Air spring strut with elastic piston bearing

A technology of air springs and struts, applied in the direction of springs, vehicle springs, elastic suspensions, etc., can solve the problems of increased frictional contact and increased wear, and achieve the effect of a simple manufacturing method or connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

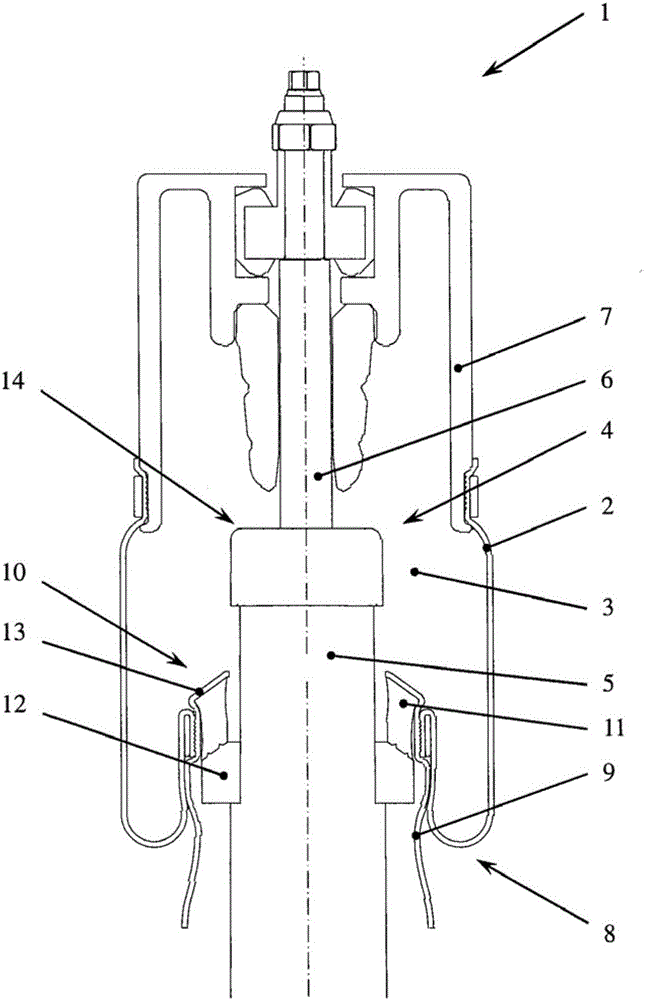

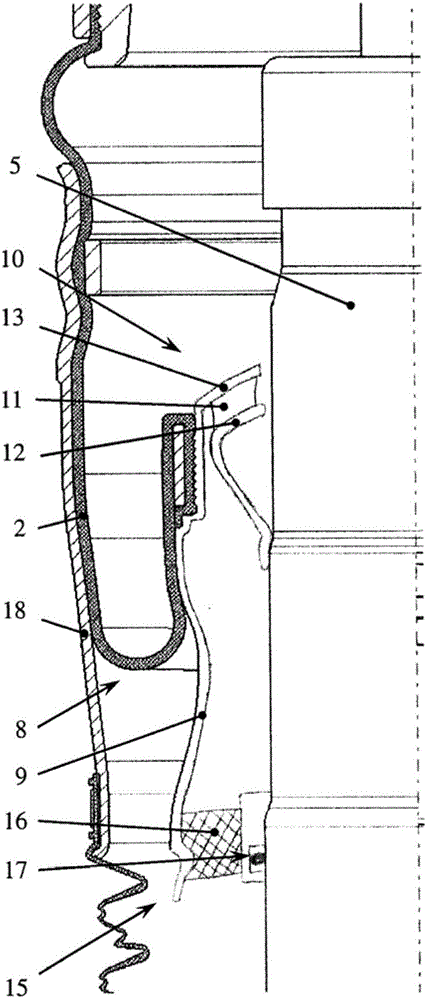

[0025] figure 1 An air spring strut 1 for a passenger car is shown. The air spring bellows 2 consists of rubber reinforced with reinforcement components and surrounds the working chamber 3 . Also centrally located inside the working chamber is a telescopic damper 4 which has a housing which is formed as a damper cylinder 5 with an internally located damping piston not shown in detail, and which There is also a piston rod 6 connected to the damping piston.

[0026] The air spring bellows 2 is fastened at one upper end to the air spring cover 7 and at the other lower end to form a bead 8 on the air spring piston 9 connected to the damper cylinder 5 and can be The air spring coils up on the outside of the piston.

[0027] The air spring piston 9 is connected at its upper end above the bead 8 to the damper cylinder 5 via an elastic bearing 10 .

[0028] The elastic support 10 consists of an elastic body 11, here a rubber body, which is arranged on a collar 12 protruding axiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com