Power cable basket structure for large-sized wind generating set

A technology for wind turbines and power cables, which is applied in the direction of cable installation, cable installation devices, electrical components, etc., and can solve problems such as potential safety hazards, misalignment of power cables, and easy wear and tear on the cable sheath

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

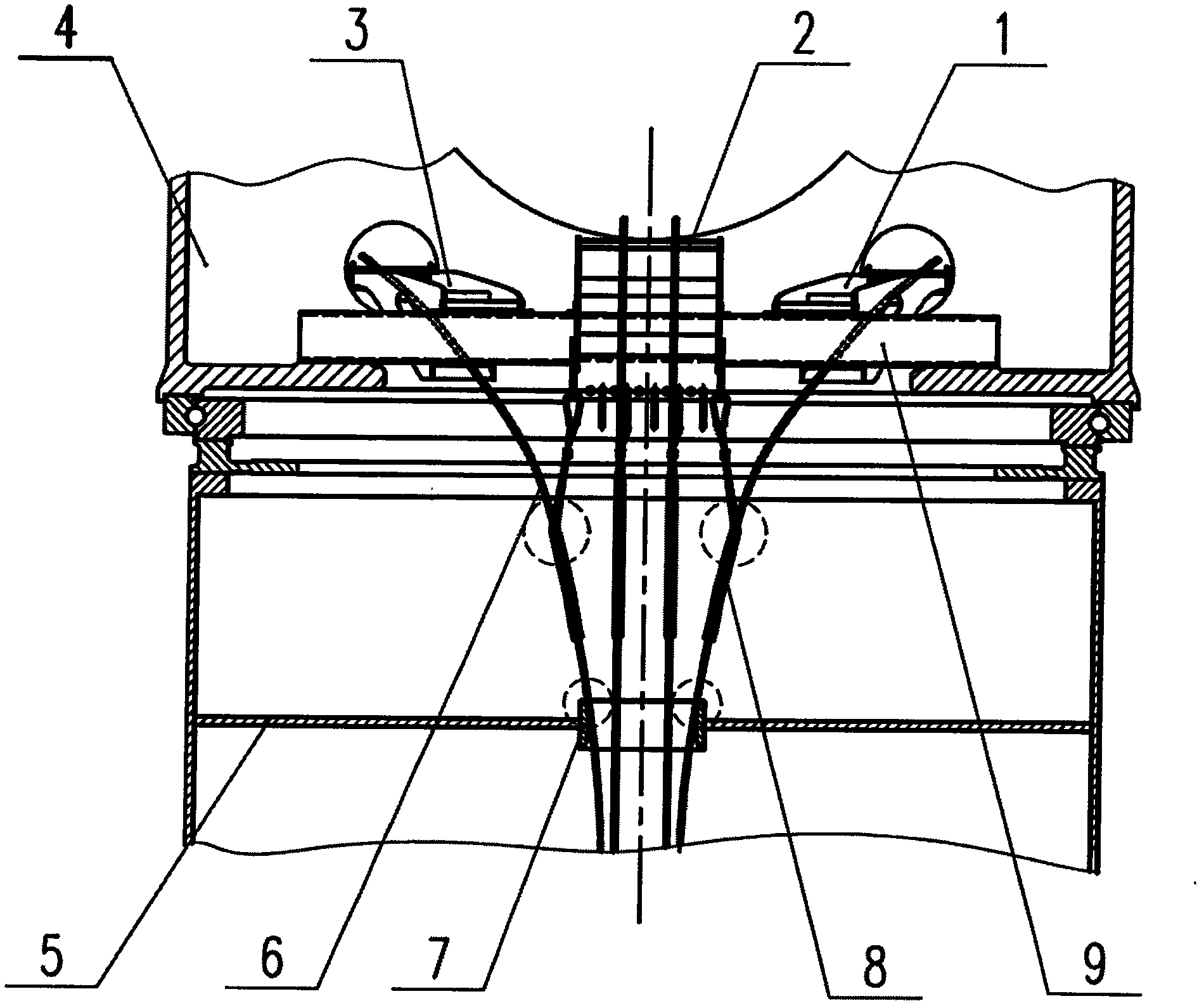

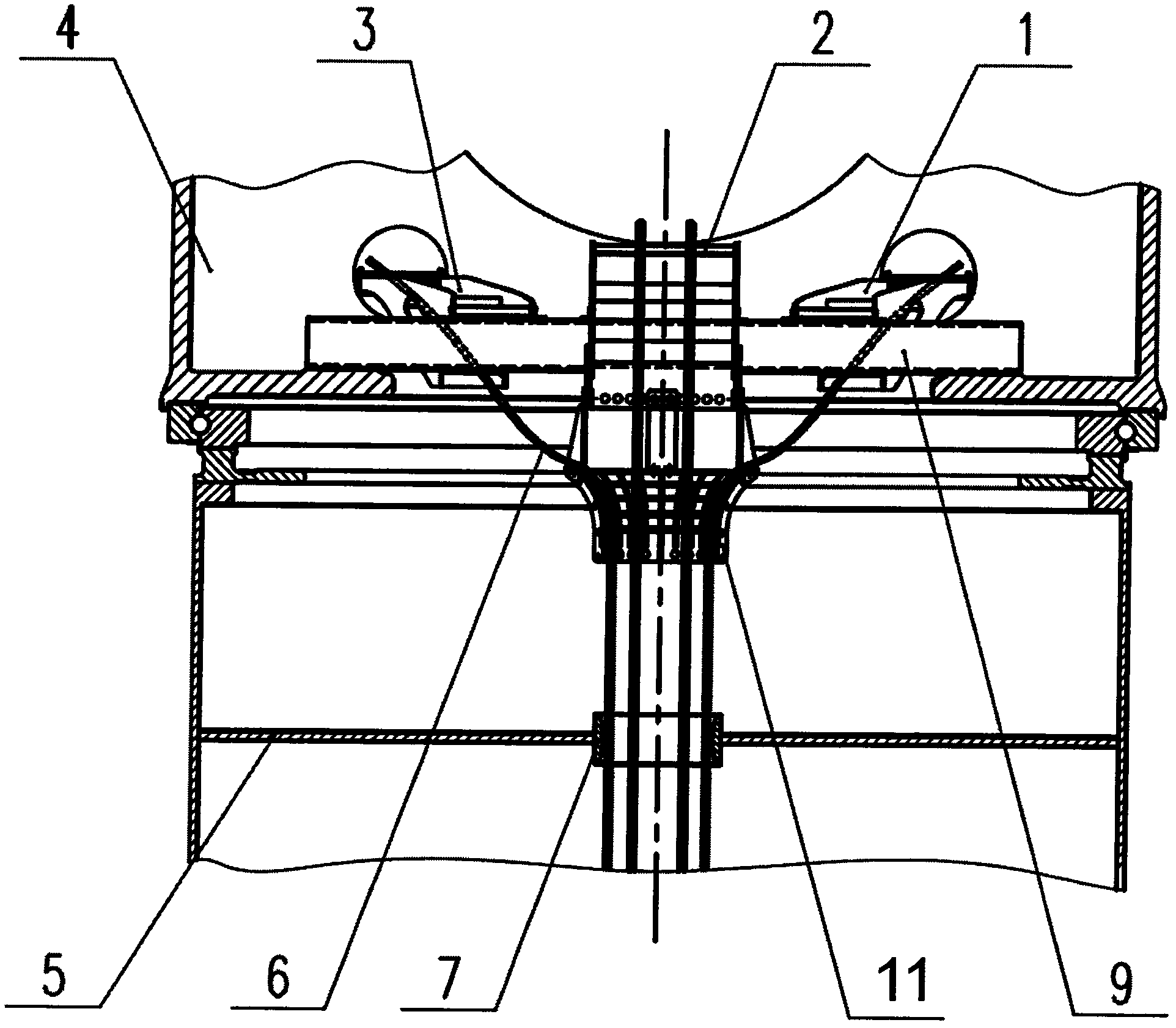

[0013] figure 1 The structure of the wind power generating set using the cable net is shown in , the power cables (6) enter the tower from the right cable rack (1), the middle cable rack (2), and the left cable rack (3). , the power cable (6) is fixed on the U-shaped hanging plate (10) on the channel steel beam (9) at the bottom of the engine room through the cable net (8), because the cable net (8) needs to bear the power cable (6) Due to the weight and the misalignment of the power cables (6) on both sides, the outer skin of the power cables (6) is easily damaged during the operation of the wind turbine, and the damage mainly occurs in the figure 1 In the circle of the dotted line, damage to the sheath of the power cable (6) will bring a major safety hazard to the wind power generating set.

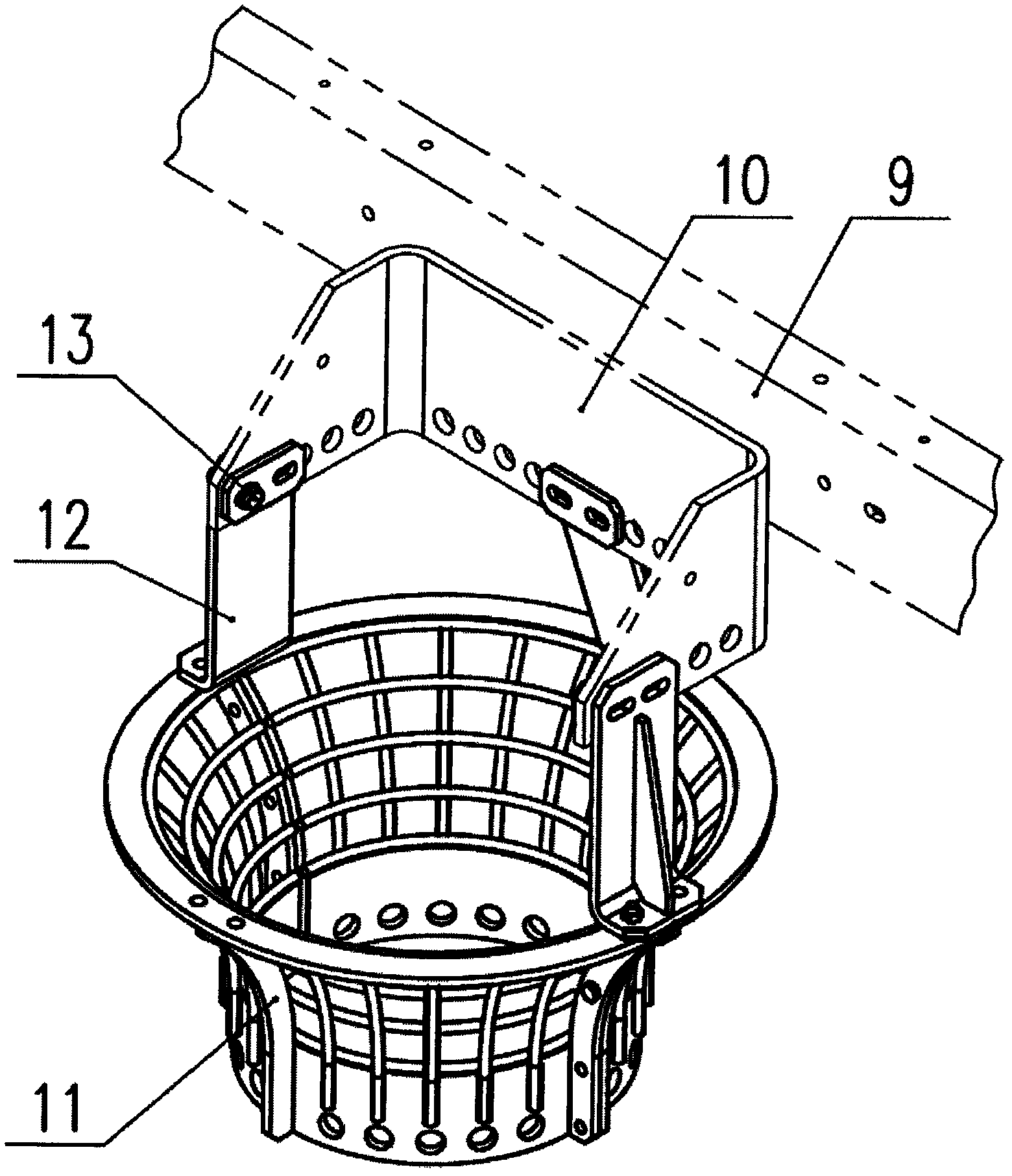

[0014] figure 2 It is a structural diagram of the power cable hanging basket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com