Method for controlling rusting of bottle cap by detecting water residue in skirt teeth of bottle cap

A technology of water volume control and bottle cap, applied in the direction of non-electric variable control, control/regulation system, simultaneous control of multiple variables, etc., to achieve maintenance satisfaction, reduce economic losses, and avoid corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for controlling bottle cap corrosion by detecting the amount of residual water in the bottle cap skirt teeth, comprising the following steps:

[0030] ① Preparation: Select precision test paper with a pH range of 5.5-9.0. The length of the test paper is 61 mm and the width is 9 mm; 10 squares of equal area are marked;

[0031] ② Formulate evaluation criteria for residual water in bottle cap skirts:

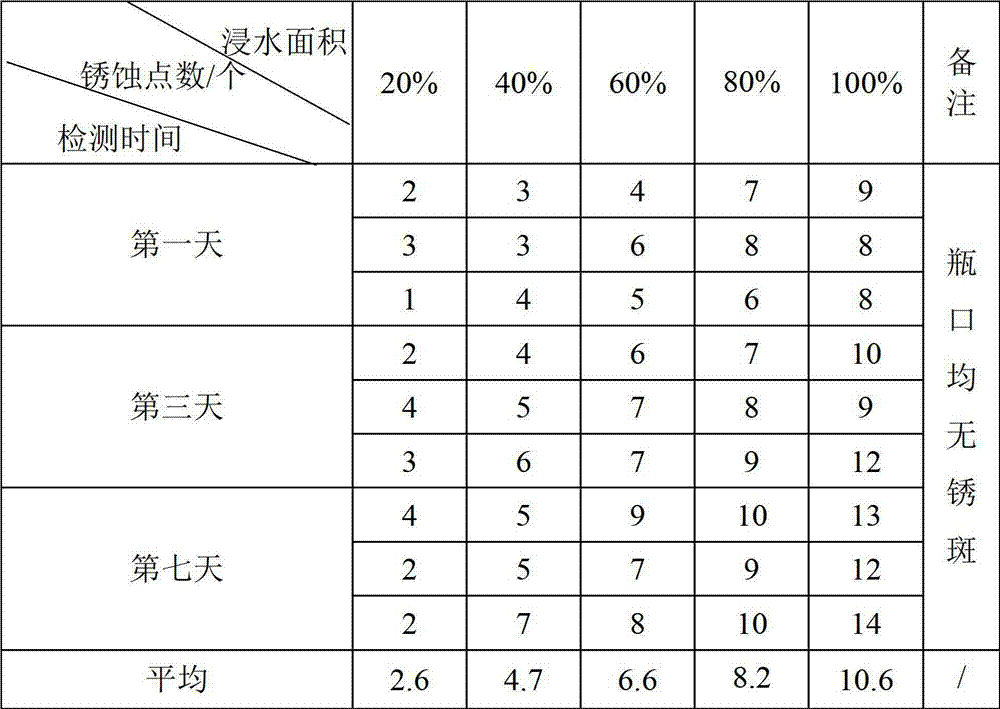

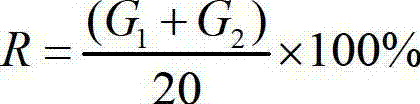

[0032] a. Take two identical aliquots of pH test paper for the test, add a certain amount of water to the two aliquots of pH test paper arranged side by side, and obtain a total water soaking area of 20% (4 grids) and 40% (8 grids) respectively. , 60% (12 grids), 80% (16 grids) and 100% (20 grids) water soaking amount;

[0033] b. Blow off the residual water in the cap skirt teeth, and according to the corresponding relationship between the water immersion area and the water immersion amount obtained in step ② (a), pipette an appropriate amount of water and blo...

Embodiment 2

[0046] A method for controlling bottle cap corrosion by detecting the amount of residual water in the bottle cap skirt teeth, comprising the following steps:

[0047] ① Preparation: Select precision test paper with a pH range of 5.5-9.0. The length of the test paper is 61 mm and the width is 9 mm; 10 squares of equal area are marked;

[0048] ② Formulate evaluation criteria for residual water in bottle cap skirts:

[0049] a. Take two identical aliquots of pH test paper for the test, add a certain amount of water to the two aliquots of pH test paper, and obtain the total water immersion area as 20% (4 grids), 40% (8 grids), and 60% respectively (12 grids), 80% (16 grids) and 100% (20 grids);

[0050] b. Blow off the residual water in the cap skirt teeth, and according to the corresponding relationship between the water immersion area and the water immersion amount obtained in step ② (a), pipette an appropriate amount of water and blow it evenly into the bottle cap skirt teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com