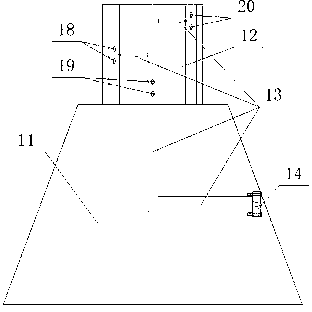

Wind cup type fiber Bragg grating wind speed and direction sensor

A wind speed, direction and sensor technology, applied in instruments, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problem of large sensor hysteresis, low sensor measurement accuracy and sensitivity, wind resistance easily affected by wind speed, wind direction and impurities in the wind impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] When the sensor measures the displacement of the fiber Bragg grating =0.001nm, =0.001nm, , put the data into the formula (11), and obtain the wind angle tangent value as:

[0091] = 0.578

[0092] Calculate the wind direction angle according to the inverse trigonometric function:

[0093] = =30.03°

[0094] wind angle =30° and the various parameters of the sensor are brought into the formula (12), and the wind speed is obtained as:

[0095] =1.20 m / s.

Embodiment 2

[0097] When the sensor measures the displacement of the fiber Bragg grating =0.096nm, =0.424nm, , the calculated wind direction angle =10.01°, wind speed =19.99m / s.

Embodiment 3

[0099] When the sensor measures the displacement of the fiber Bragg grating when =0.519nm, = -0.424nm, , , the calculated wind direction angle =110.01°, wind speed =19.99m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com