Stem content in leaf infrared imaging detection method based on active heating

A detection method and infrared imaging technology, which is applied in the direction of measuring devices, test sample preparation, instruments, etc., can solve the problems of long detection cycle, hysteresis, and inability to meet the real-time control of production dynamics well, and achieve processing speed Fast, high efficiency, overcome the effect of long detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

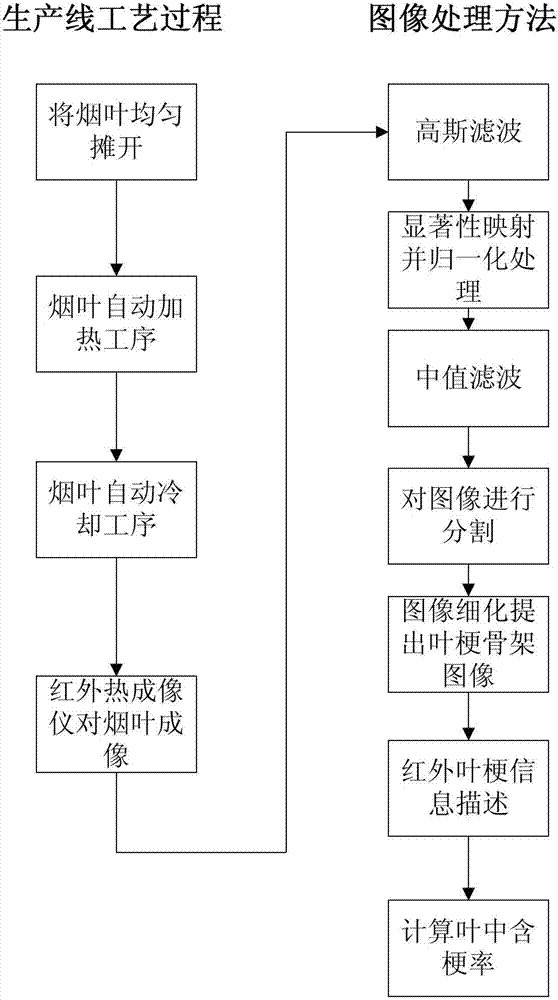

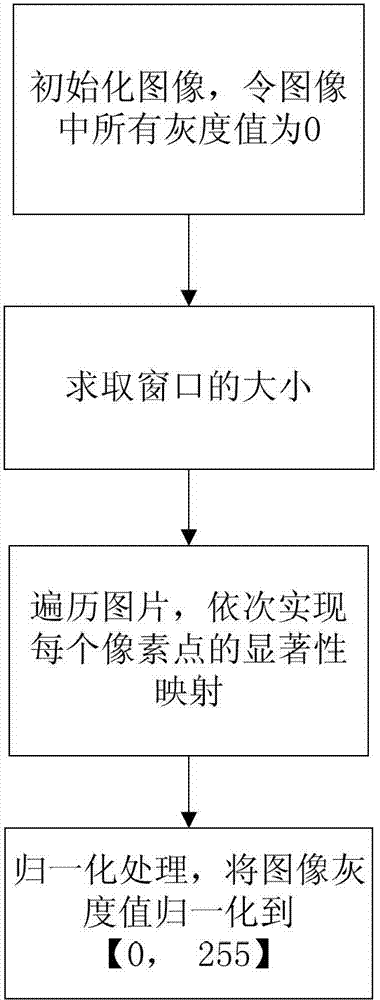

[0028] The invention is based on an actively heated infrared imaging detection method for stalks in leaves, combined with an application example of a threshing and redrying production line. Such as figure 1 ,Proceed as follows:

[0029] In the first step, the tobacco leaves are evenly thinned through the vibrating plate and the acceleration belt, and the thinned tobacco leaves enter the oven along with the conveying production line;

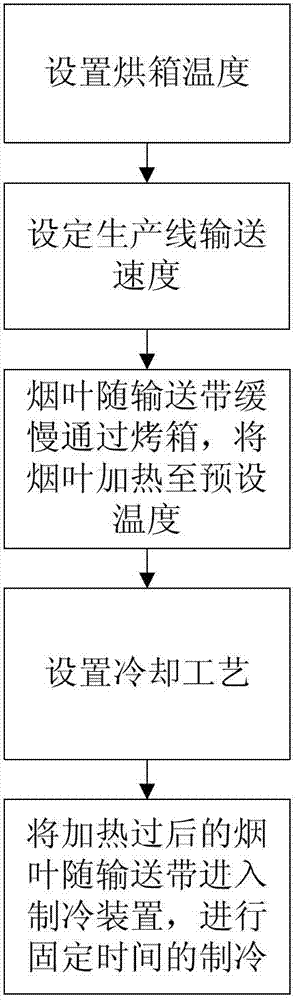

[0030] The second step, such as figure 2 , Tobacco automatic heating process. Set the conveying speed of the production line and the temperature of the oven so that the tobacco leaves are heated to 50-100 degrees after passing through the process. In this embodiment, the temperature of the oven is set at 120-200 degrees, and the speed of the production line is 1-3 m / s.

[0031] The third step is the automatic rapid cooling process of tobacco leaves. After the automatic heating is completed, the tobacco leaves are cooled, and the cooling pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com