Fast lofting method for connecting points of overhead line system of railway tunnel and automatic measuring system

A tunnel contact and measurement system technology, which is applied in the direction of measuring devices, measuring instruments, surveying and navigation, etc., can solve the problems of untimely processing, low safety factor, and unguaranteed accuracy, etc., and achieves shortened stakeout time, easy and fast operation, and guaranteed The effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The new method for quickly setting out the connection point of the railway tunnel catenary of the present invention is specifically carried out according to the following steps:

[0044] Step 1: Make the tripod of the automated measurement system;

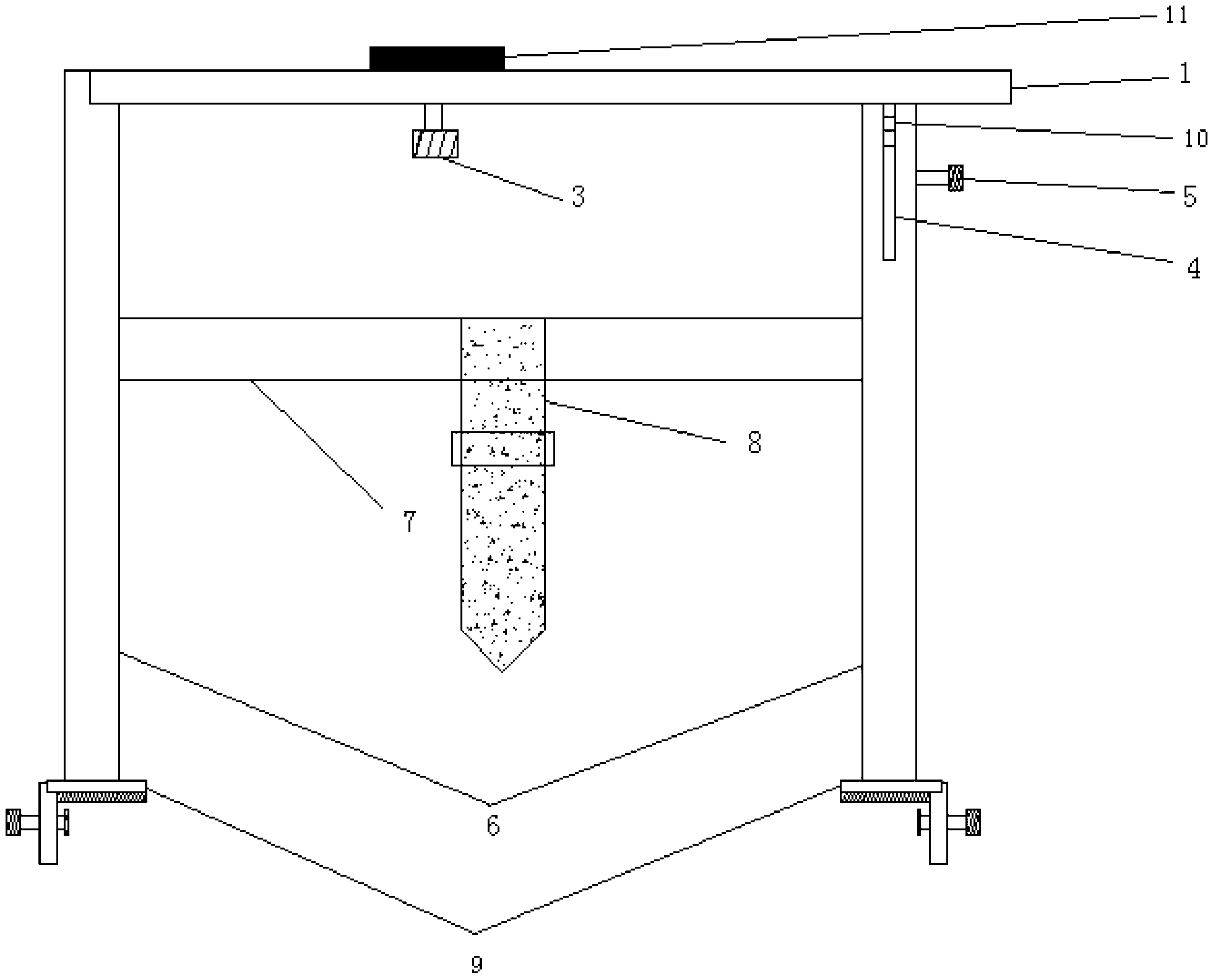

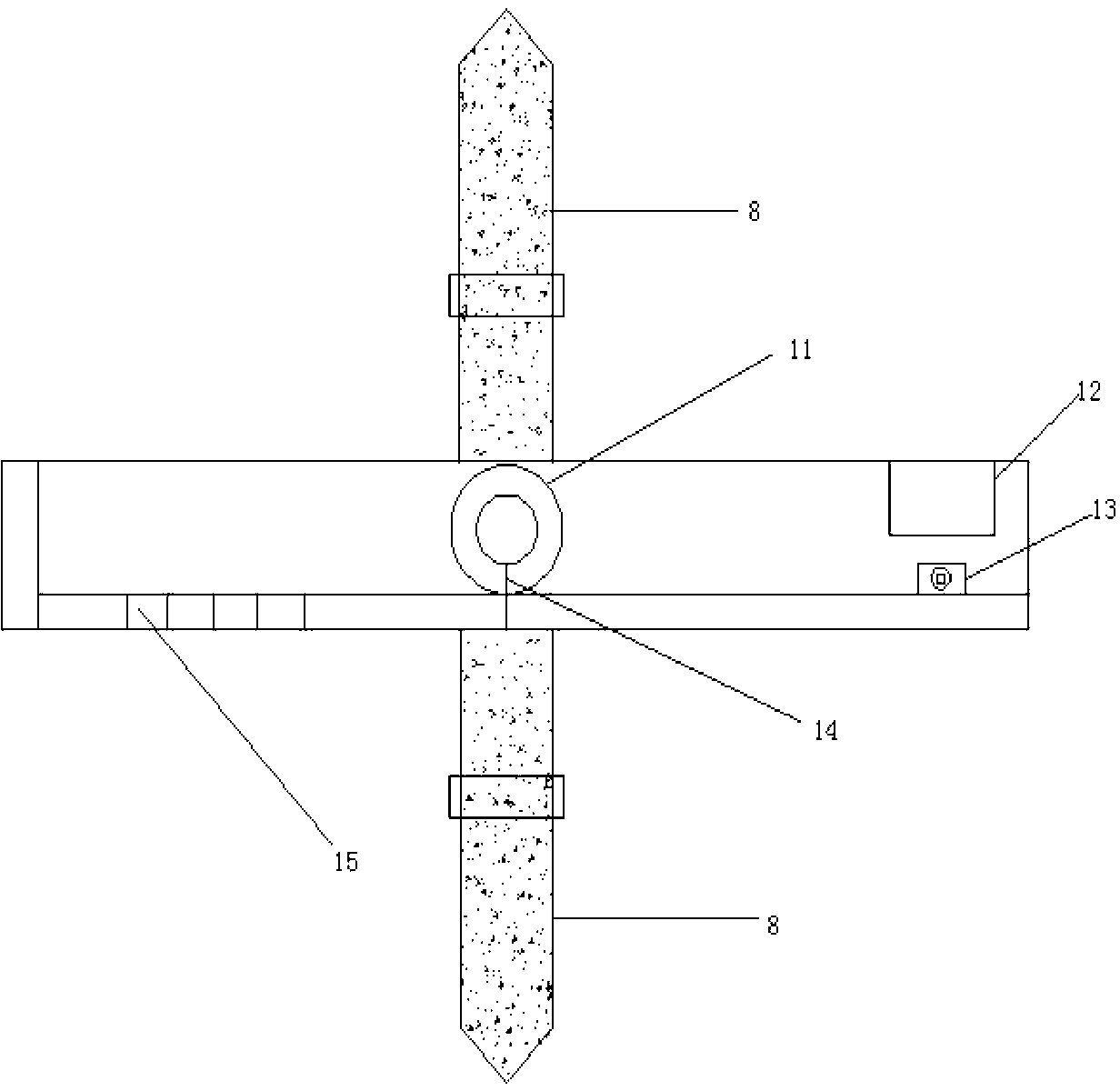

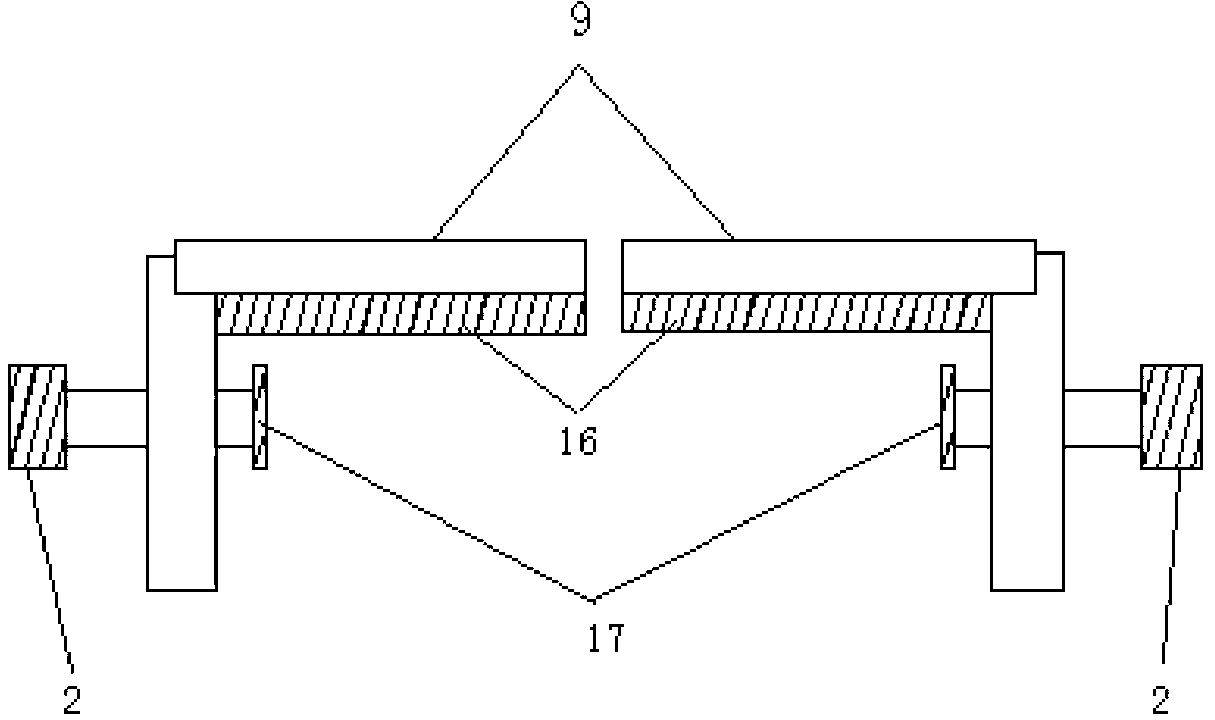

[0045] The automated measurement system includes a tripod and a total station installed on the tripod. see Figure 1-Figure 3 , the tripod includes a rectangular workbench 1, pillars 6 are respectively installed below the two ends of the workbench 1 in the length direction, and the top of one of the pillars 6 is connected to one end of the workbench 1 through a rotating shaft, and the workbench 1 can rotate around the rotating shaft; The upper part of another pillar 6 is hollow, and a telescopic rod 4 is inserted therein. The upper end of the telescopic rod 4 is connected with the workbench 1 through a rotating shaft, and the telescopic rod 4 can rotate around the rotating shaft; the telescopic rod 4 can move up and down in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com