High-pressure heat-storing/or cold-storing device

A cold storage device and heat storage technology, which is applied in the direction of household refrigeration devices, heat storage equipment, energy storage, etc., can solve the problems of increased heat capacity of the tank wall, reduced heat/cold storage efficiency, and difficult recovery of heat/cold energy. Achieve the effect of high thermal energy grade, low cost and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

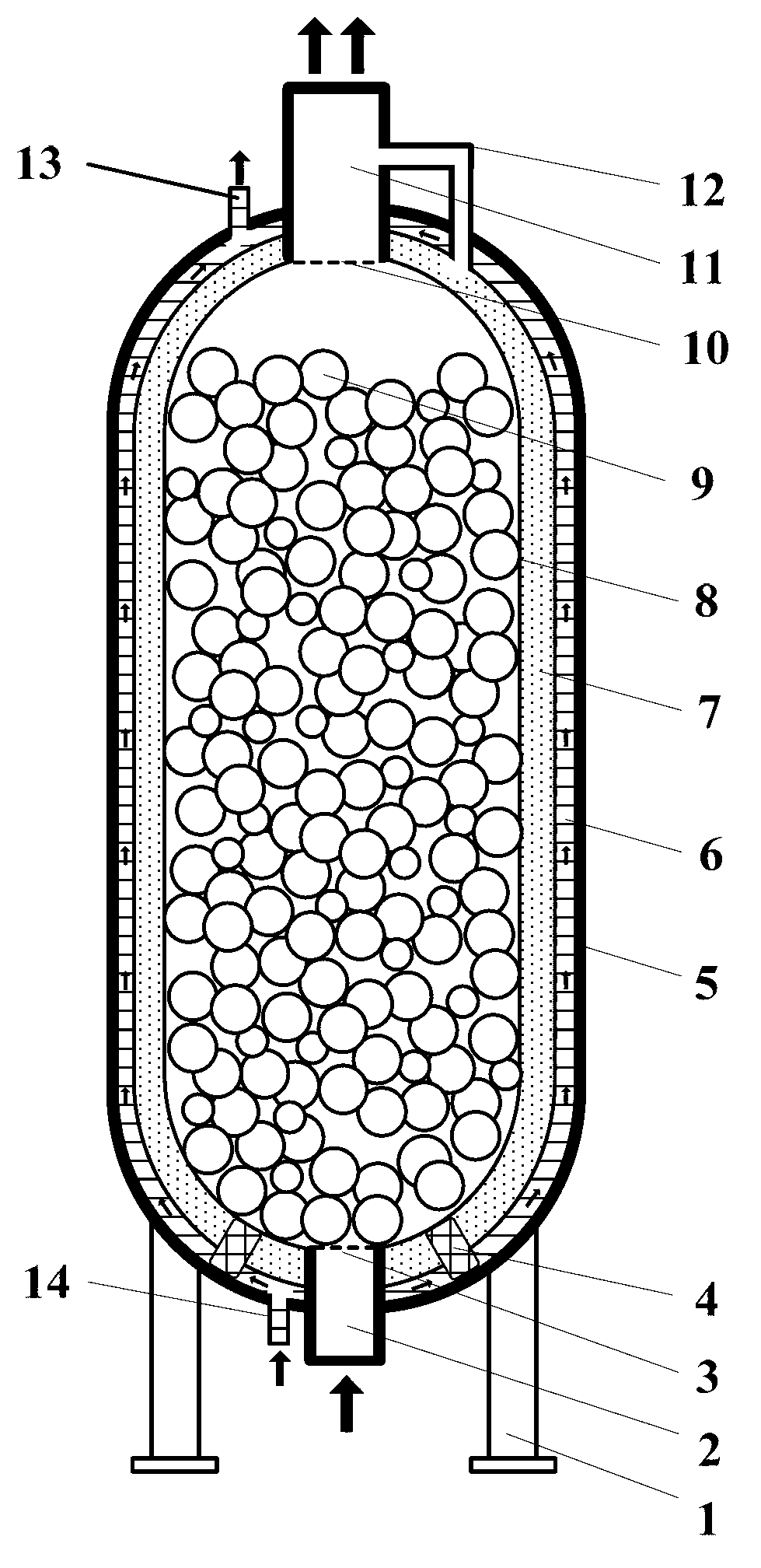

Embodiment 1

[0040] like figure 1As shown, it is embodiment 1 of the high-pressure heat storage / cold storage device of the present invention. In this embodiment, the top feed port and the top heat transfer medium nozzle are the same opening, and the bottom discharge port and the bottom heat transfer medium nozzle are same opening. Among them, including the base 1, the bottom discharge port and the bottom heat transfer medium nozzle 2, the bottom porous baffle 3, the inner shell support device 4, the thick-walled shell 5, the cooling / heating liquid layer 6, the insulation layer 7, the thin-walled Inner shell 8, solid heat storage / cold medium 9, top porous baffle 10, top feed inlet and top heat transfer medium nozzle 11, pressure pipe 12, top cooling / heating liquid nozzle 13, bottom cooling / heating Liquid nozzle 14. One end of the pressure pipe 12 communicates with the top heat transfer medium nozzle 11 , and the other end communicates with the insulation layer 7 after passing through the ...

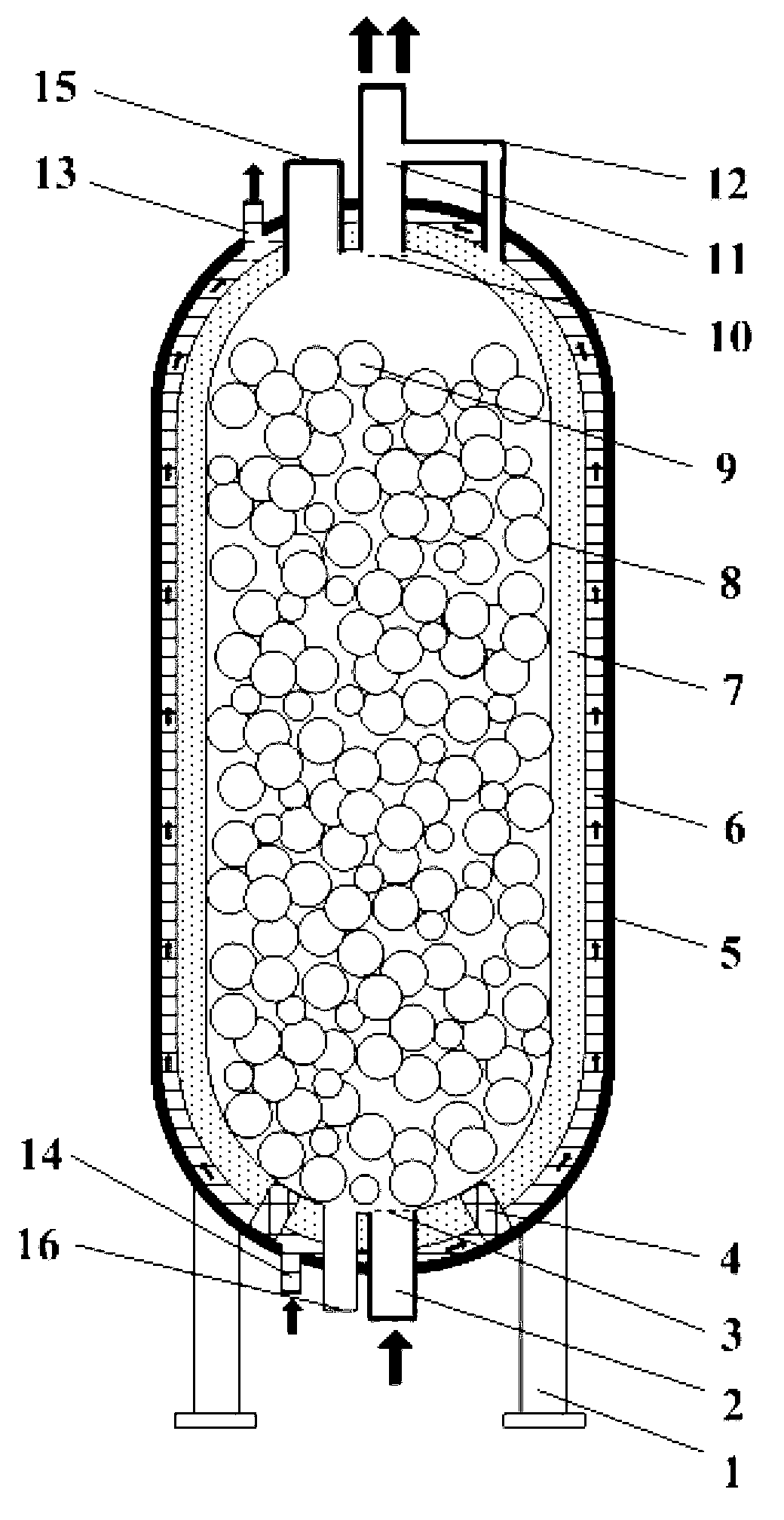

Embodiment 2

[0047] like figure 2 As shown, it is Embodiment 2 of the high-pressure heat storage / cold storage device of the present invention. In this embodiment, the top feed port and the top heat transfer medium nozzle are different openings, and the bottom discharge port and the bottom heat transfer medium nozzle are different openings. Open your mouth. Among them, including base 1, bottom heat transfer medium nozzle 2, bottom porous baffle 3, inner shell support device 4, thick-walled outer shell 5, cooling / heating liquid layer 6, insulation layer 7, thin-walled inner shell 8, solid Heat storage / cold medium 9, top porous baffle 10, top heat transfer medium nozzle 11, pressure pipe 12, top feed inlet 15, top cooling / heating fluid nozzle 13, bottom cooling / heating fluid nozzle 14 , Bottom discharge port 16. One end of the pressure pipe 12 communicates with the top heat transfer medium nozzle 11 , and the other end communicates with the insulation layer 7 after passing through the thic...

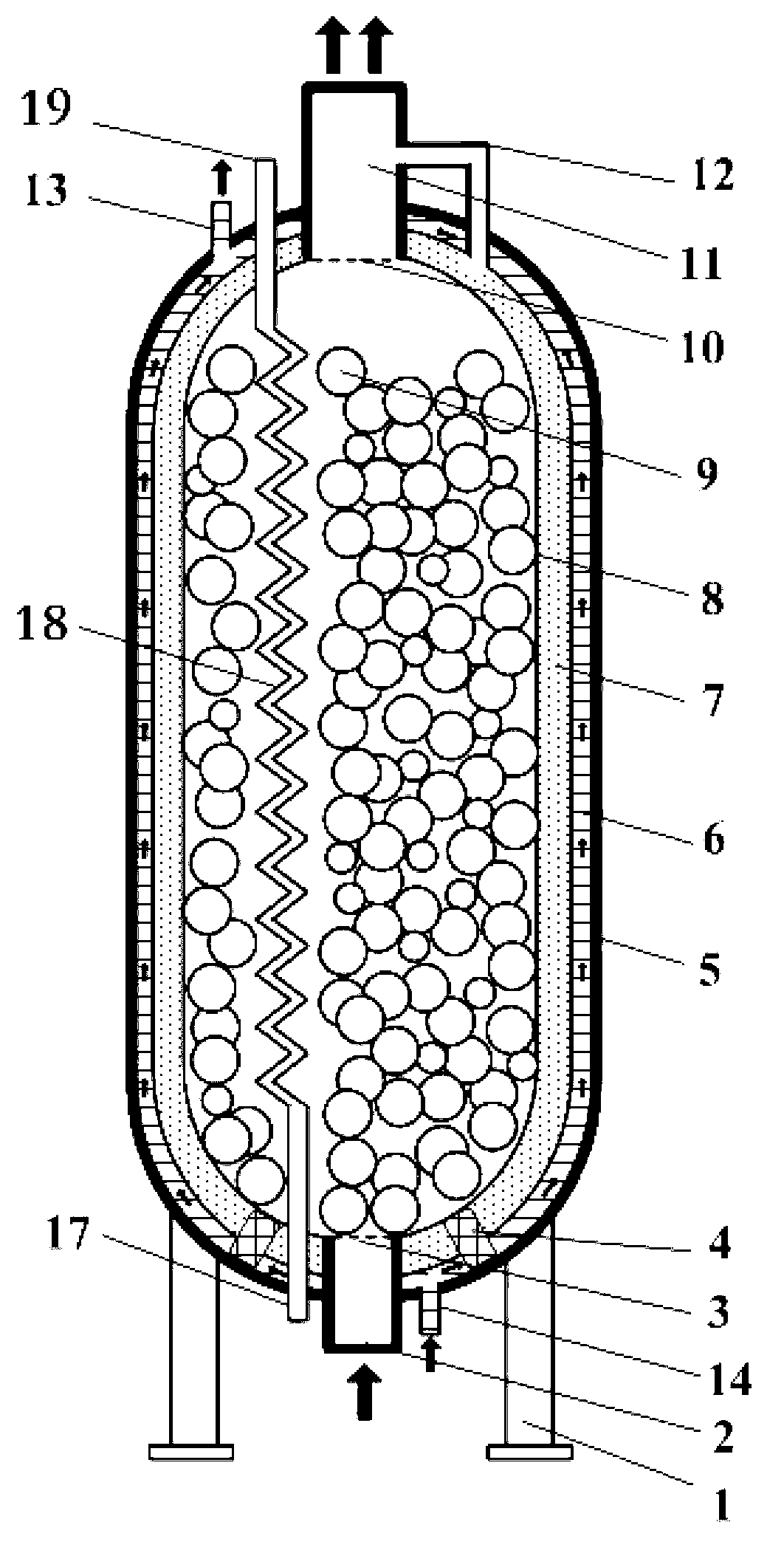

Embodiment 3

[0054] like image 3 Shown is Embodiment 3 of the high-pressure heat / cold storage device of the present invention, which is an improvement of Example 1. In this embodiment, heat exchange tubes / tube bundles are arranged vertically inside the high-pressure heat / cold storage device. In the links of storage, release and heat preservation, high / low temperature heat transfer fluids of different pressures can pass through the heat exchange tubes / tube bundles to supplement heat / cold capacity for the internal heat storage / cold medium.

[0055] Among them, including base 1, bottom discharge port and bottom heat transfer medium nozzle 2, bottom cooling / heating liquid nozzle 14, bottom porous baffle 3, inner shell support device 4, thick-walled outer shell 5, cooling / heating liquid Layer 6, insulation layer 7, thin-walled inner shell 8, solid heat storage / cold medium 9, top porous baffle 10, top inlet and top heat transfer medium nozzle 11, pressure pipe 12, heat exchange tube / Tube bund...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com