Novel oxyhydrogen flame gun

A flame gun, hydrogen and oxygen technology, applied in the field of machinery, can solve the problems that the temperature of the hydrogen and oxygen flame cannot be controlled at will, the loss of precious items, and can only be controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

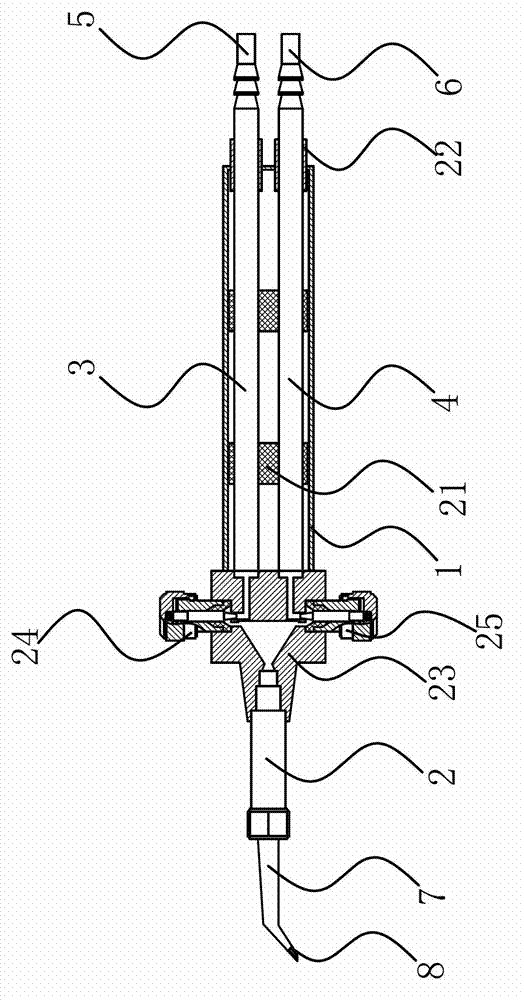

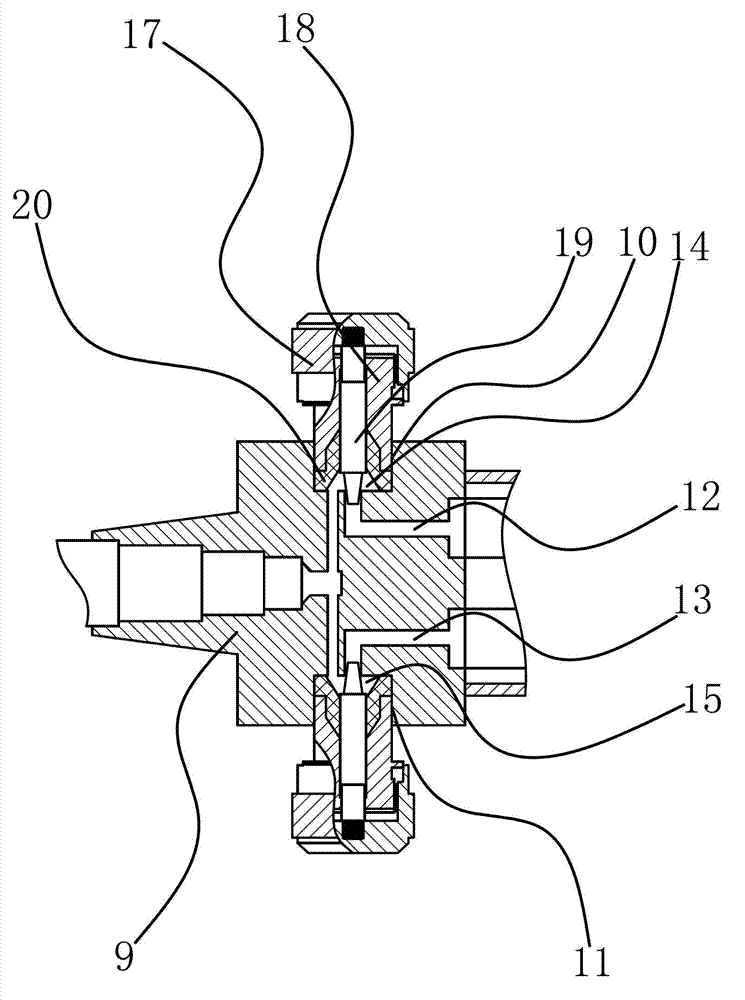

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention. In order to clearly express the structure of the present invention, the embodiments all take the upper and lower arrangement of the hydrogen regulating valve and the oxygen regulating valve as an example. In practice In the application, it is advisable to arrange the hydrogen regulating valve and the oxygen regulating valve adjacent to each other for convenient operation, but the present invention is not limited to these embodiments.

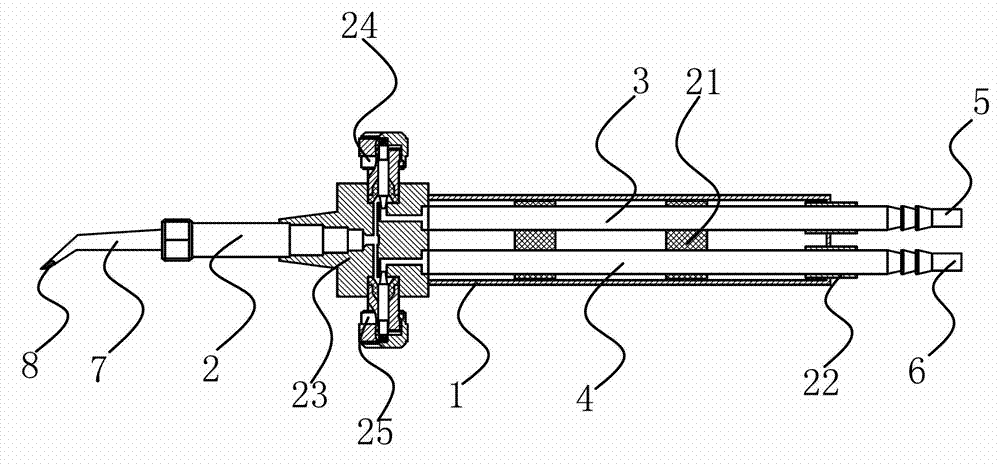

[0022] Such as figure 1 and figure 2 As shown, a novel hydrogen-oxygen flame gun comprises a gun shaft 1, a mixed gas output pipe 2, a hydrogen inlet pipe 3, an oxygen inlet pipe 4, a hydrogen inlet pipe connector 5, an oxygen inlet pipe connector 6 and a regulating device 23 and is connected with The gun nozzle 7 that is threaded and sealed at the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com