Automobile timing driving belt for oil immersion

A technology for transmission belts and automobiles, applied in the directions of transmission belts, belts/chains/gears, fiber types, etc., can solve the problems of large power consumption, troublesome maintenance, and high noise of chain transmission, and achieve light weight, save use and maintenance costs, and reduce noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

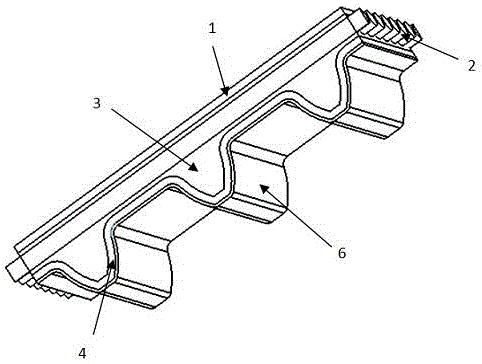

[0035] An automobile timing drive belt for immersion in oil, see figure 1 and figure 2 , including an annular belt body 5, a plurality of teeth 3 formed at intervals along the inner peripheral surface of the belt body and a core wire 2 embedded along the circumference of the belt body, the outer peripheral surface of the belt body is provided with a back fabric layer 1 The inner peripheral surface of the belt body is provided with a toothed fabric layer 4 covering the teeth, and the outer surface of the toothed fabric layer is coated with a fluorine-containing emulsion coating 6. The materials and preparation process of the above structures are as follows:

[0036] 1. Back fabric layer: use PA66 fiber twisted into yarn to weave the canvas, after the dipping treatment of dipping glue with the same main component as the main component of the belt body (hydrogenated nitrile rubber), coating method: dipping once , The front and back sides of the canvas are painted 3 times; then...

Embodiment 2

[0059] An automobile timing drive belt for immersion in oil, the specific structure and preparation method are the same as in Example 1, the difference is that:

[0060] Wherein, the preparation of the impregnating mortar: the mixing rubber and acetone are mixed to obtain the impregnating mortar, wherein the mass ratio of the mixing rubber and acetone is 1:6. The rubber compound is prepared by mixing the following components in parts by weight: hydrogenated nitrile rubber 2020L: 100; zinc oxide: 6; stearic acid: 2; phenolic adhesive resin: 6; carbon black N330: 55; Agent TP-95: 5; white carbon black: 12; crosslinking agent DCP: 5; co-crosslinking agent TAIC: 2.

Embodiment 3

[0062] An automobile timing drive belt for immersion in oil, the specific structure and preparation method are the same as in Example 1, the difference is that:

[0063] The main body of the belt is prepared by mixing the following components in parts by weight: hydrogenated nitrile rubber 2020L: 100; aramid staple fiber: 8; zinc oxide: 8; stearic acid: 2; carbon black N774: 65; Softener TP-95: 6; white carbon black: 12; crosslinking agent DCP: 4; sulfur: 0.8.

[0064] The production process of the oil-immersed automobile timing drive belt of the present invention is the same as that of the existing product except for the above-mentioned steps. No tensioning device is required during use, and the transmission belt can be completely submerged in engine oil to achieve the same service life as the engine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com