Air spring

A technology of air springs and hollow parts, applied in the direction of gas shock absorbers, etc., can solve the problems of hindering the smooth displacement of the metal parts of the stopper parts, and it is difficult to ensure the cushioning performance, and achieve the effect of improving the cushioning performance and smooth displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

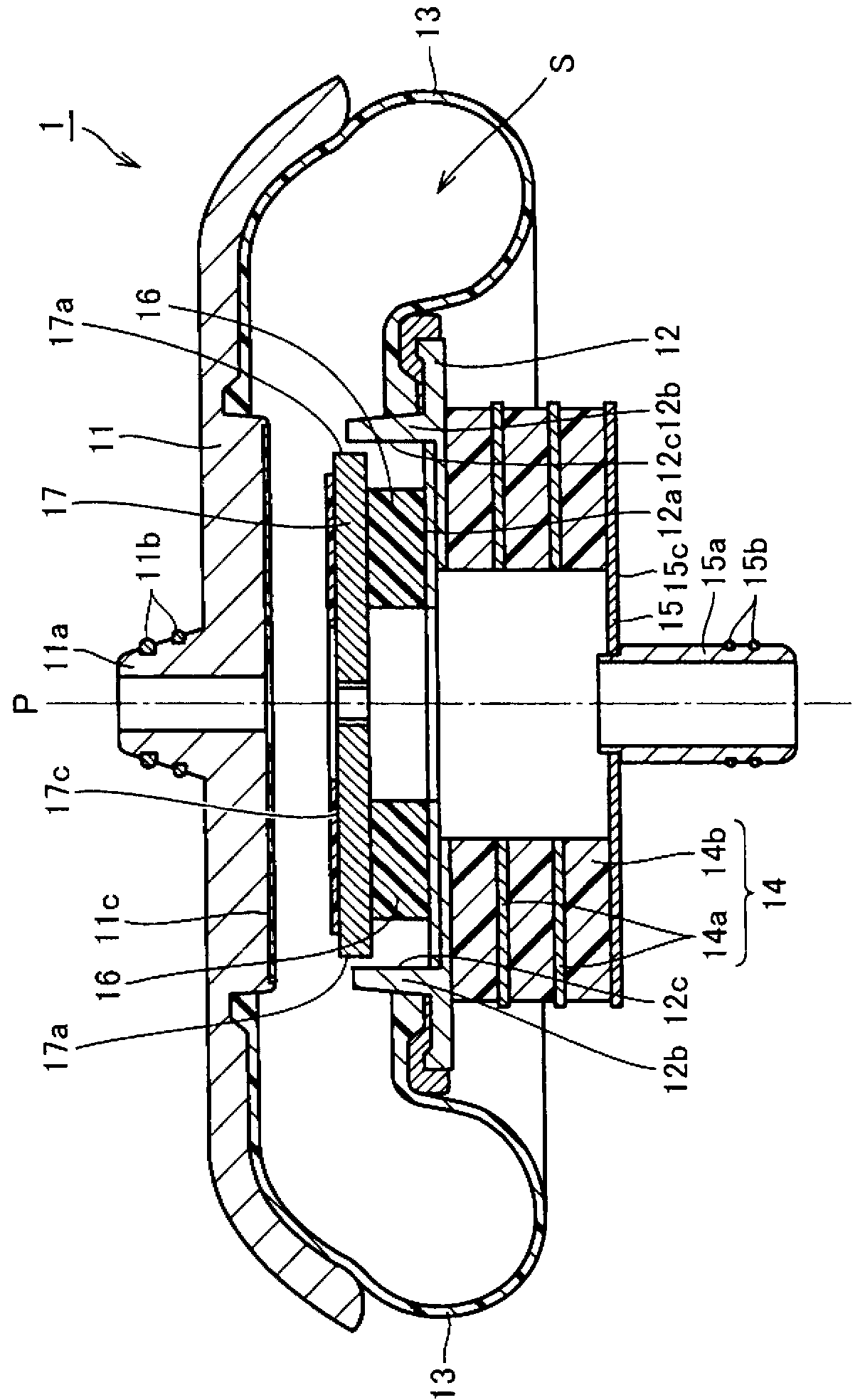

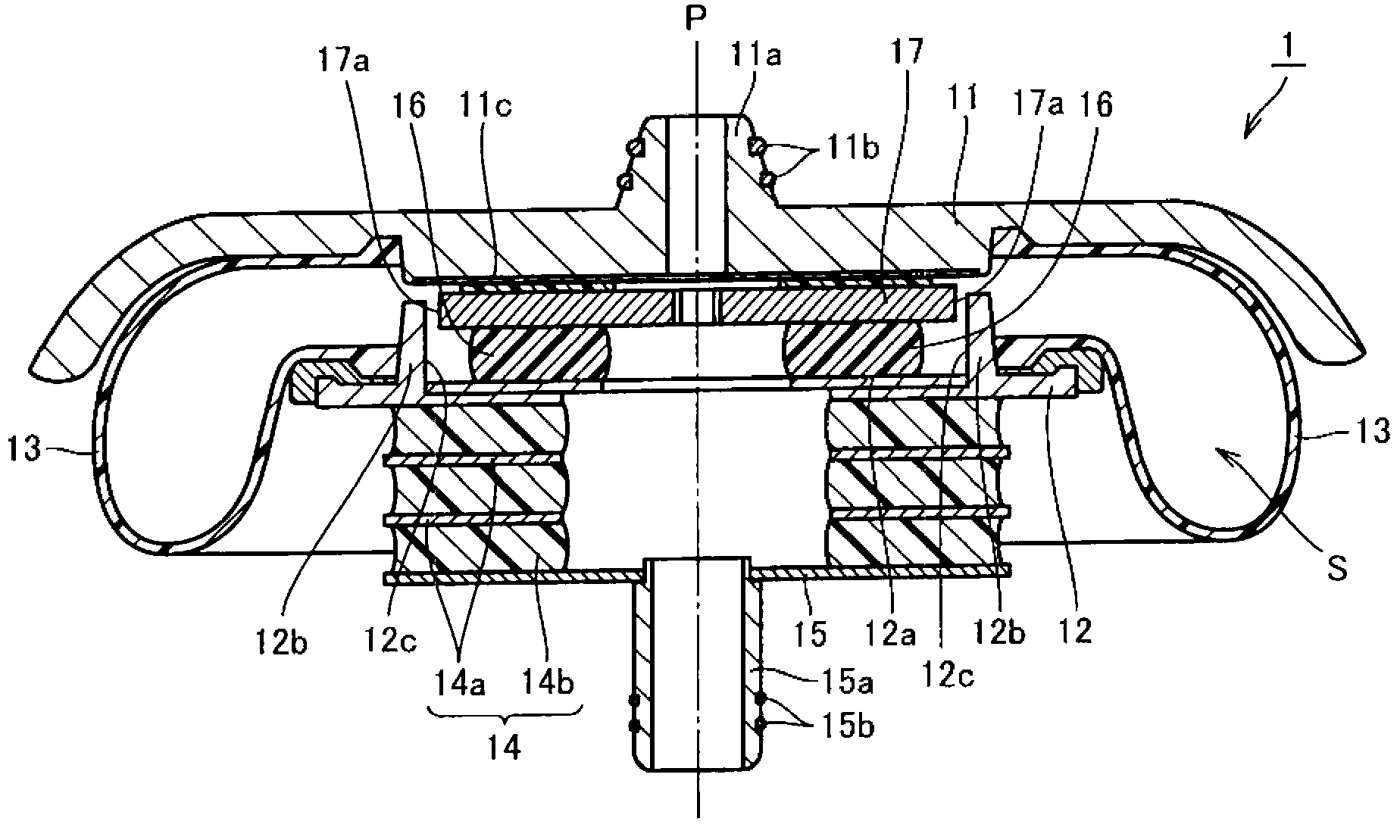

[0067] First, Embodiment 1 which is one embodiment of the present invention will be described. First, the structure of the air spring 1 of the present embodiment will be described. refer to figure 1 , The air spring 1 mainly has: the outer cylinder 11 as the first support member, the lower panel 12 as the second support member, the diaphragm 13, the outer stopper 14, the rubber lower plate 15 as the third support member, the built-in stopper member 16, and a stopper member 17 as a fourth supporting member.

[0068] In a region including the axis (central axis) P of the outer tube 11 , a vehicle body side coupling 11 a protruding along the axis P toward the side opposite to the side of the lower panel 12 is formed. An O-ring 11b is attached to the outer peripheral portion of the vehicle body side coupling 11a. The outer cylinder 11 is connected to a vehicle body side (not shown) via a vehicle body side coupling 11 a.

[0069] The lower panel 12 is arranged so as to share t...

Embodiment approach 2

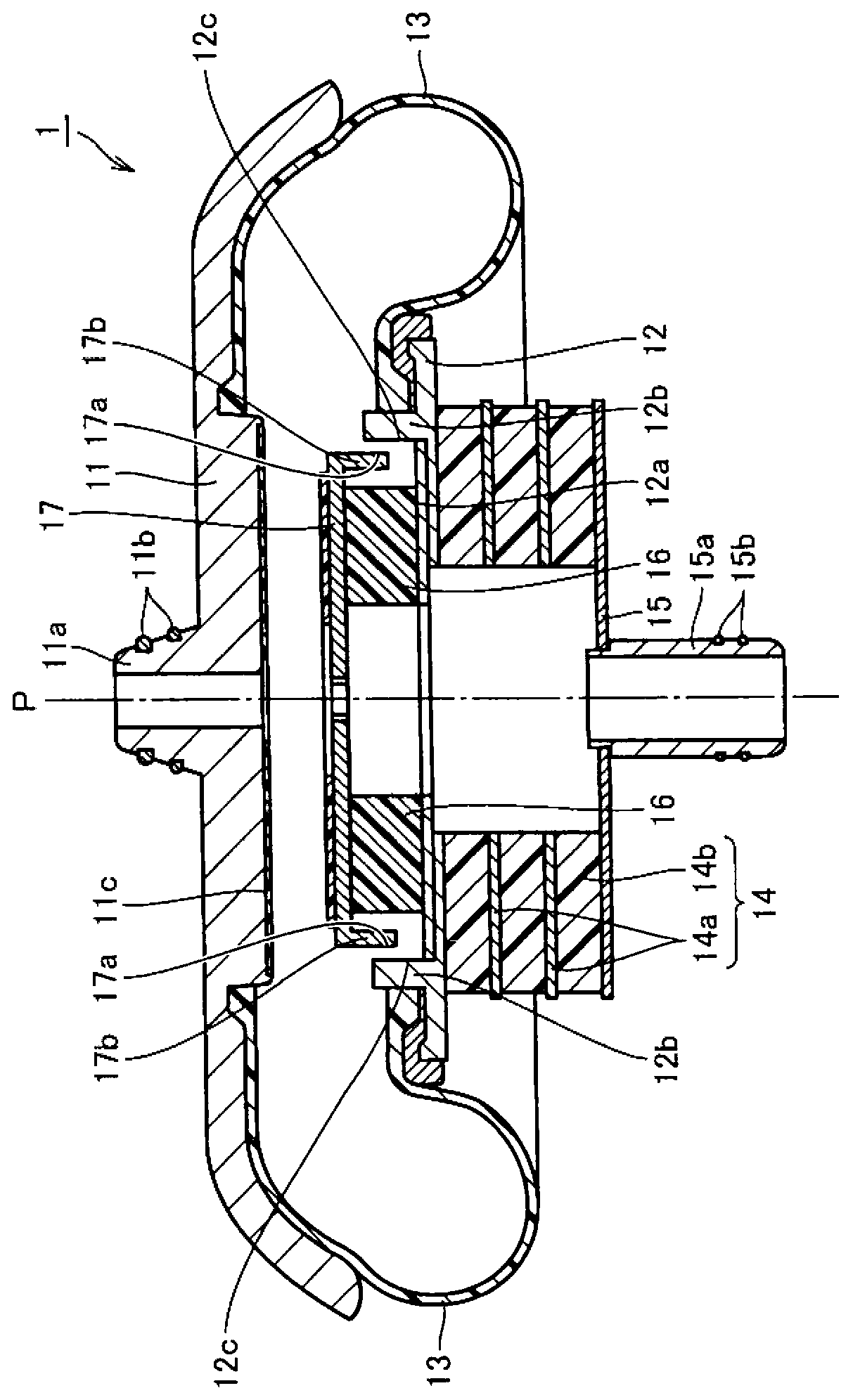

[0085] Next, Embodiment 2 which is another embodiment of the present invention will be described. The air spring 2 of the present embodiment basically has the same structure as the air spring 1 of the above-described first embodiment, and achieves the same effect. However, the air spring 2 of the present embodiment is different from the air spring 1 of the first embodiment in terms of the structure of the stopper member and the guide portion.

[0086] refer to Figure 5 , in the air spring 2, like the air spring 1, a guide portion 22b is formed on the second opposing surface 22a of the lower panel 22 facing the outer cylinder 21, and the guide portion 22b protrudes in the direction along the main load direction. , opposite to the stop member 27 in a direction perpendicular to the main load direction. Here, in this embodiment, the guide part 22b is formed on the 2nd opposing surface 22a so that it may oppose the inner peripheral surface of the stopper member 27. As shown in F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com