Air inlet pipe of integrated intercooler

An air intake pipe and intercooler technology, which is applied in the field of air intake pipes integrated with intercoolers, can solve the problems of unfavorable arrangement of other components of the engine, unfavorable installation and disassembly of the air intake system, and large space occupied by the air intake system. Conducive to intake air charge, saving layout space and improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

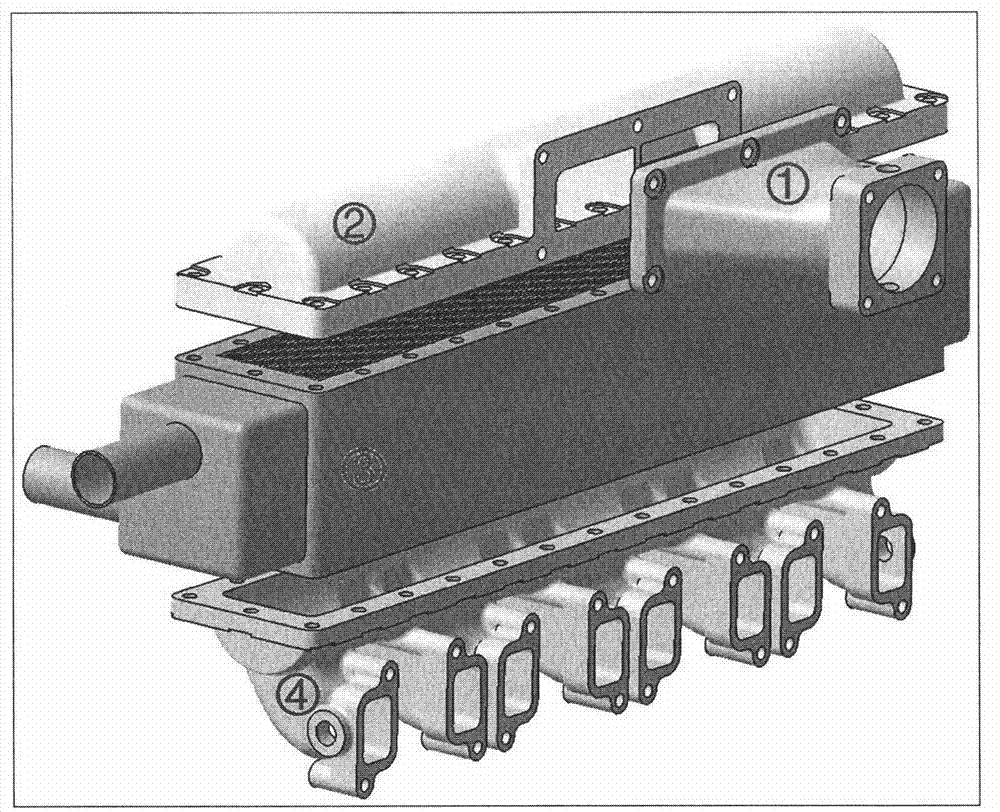

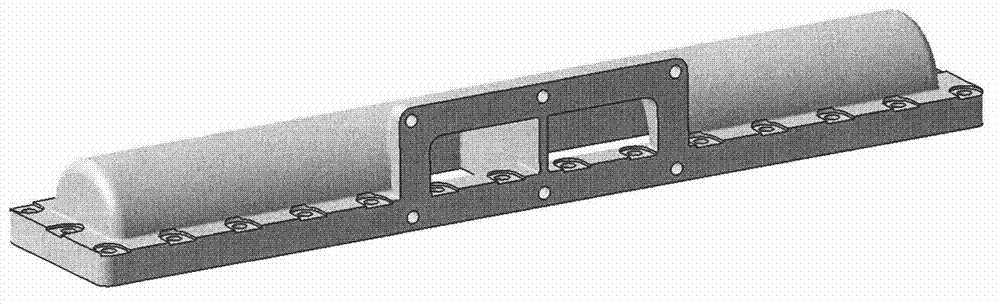

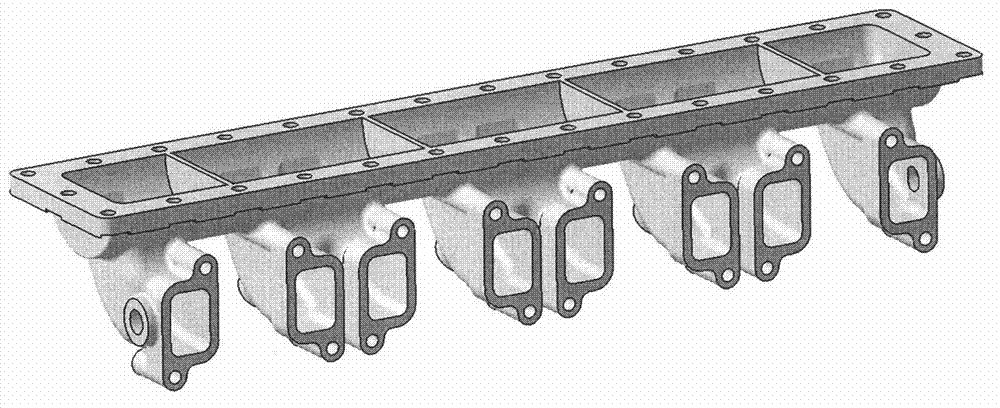

[0013] Such as figure 1 As shown, after the external fresh air is pressurized, it enters the upper air intake chamber 2 from the compressor outlet through the transition pipe 1, then enters the intercooler 3, cools down in the intercooler 3, and finally passes through the lower air intake chamber The intake manifold of 4 enters the cylinders of the engine to participate in combustion.

[0014] The upper air intake cavity partition is arranged inside the upper air intake cavity 2, so that the pressurized air evenly enters the intercooler to realize uniform cooling.

[0015] The upper air intake chamber partition is arranged in the middle of the upper air intake chamber 2, so that the pressurized air enters the left and right parts of the intercooler evenly to achieve uniform cooling.

[0016] The lower air intake chamber baffle is arranged inside the lower air intake chamber 4, so that the cooled pressurized air enters each cylinder on average, realizes uniform air intake, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com