Digging equipment

A technology of equipment and feeding machine, which is applied in the field of cutting device for processing parts, can solve the problem of difficulty in obtaining sapphire rods at one time, and achieve the effect of low processing cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

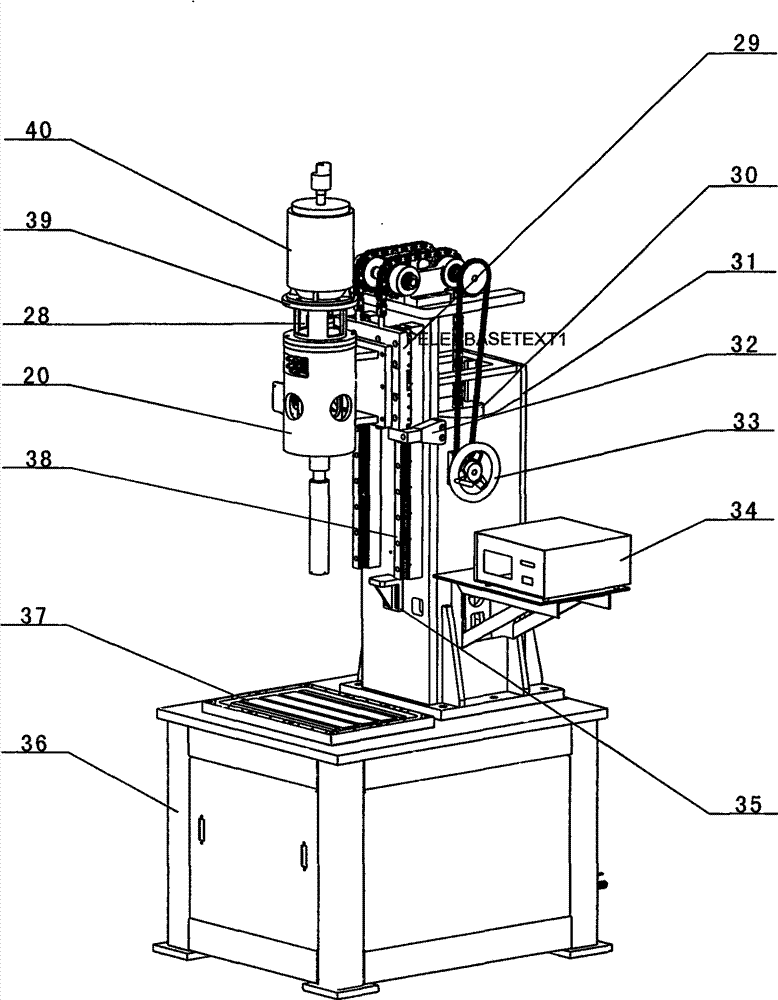

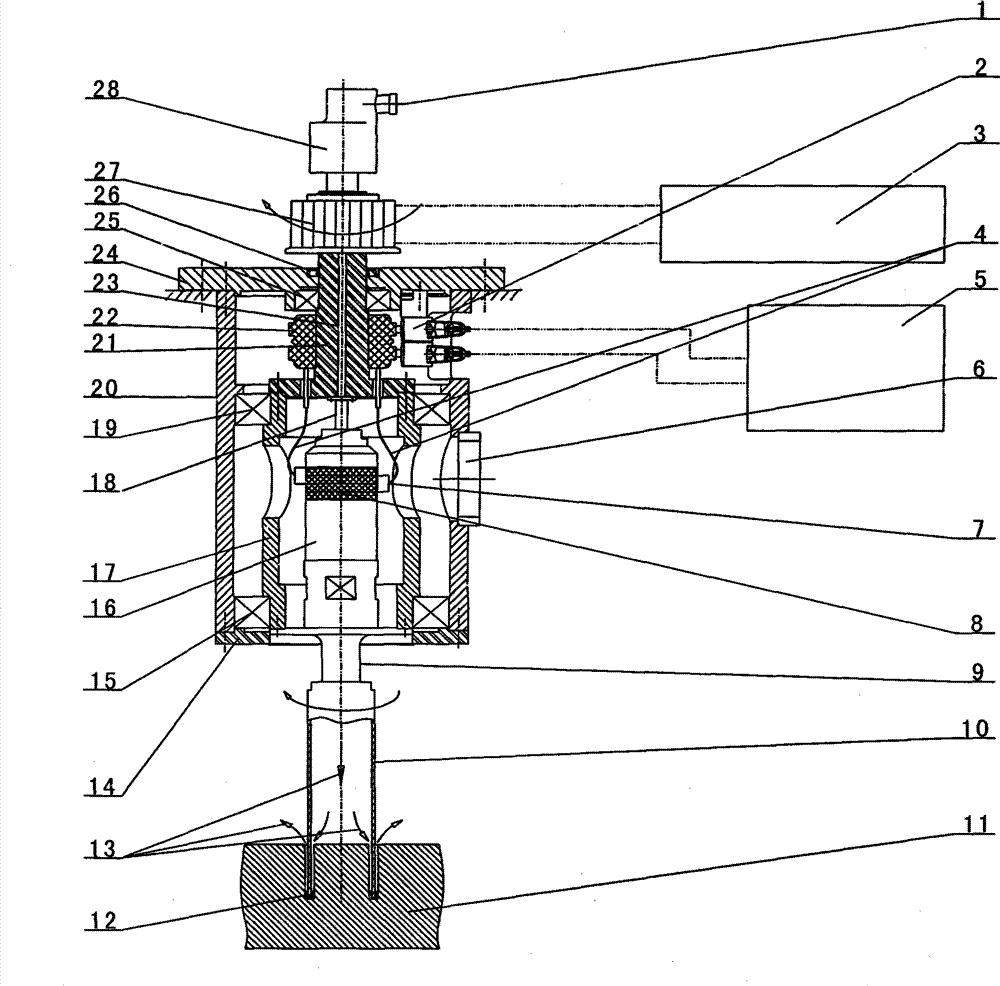

[0024] combined with figure 1 Or 2 middle digging equipment, including ultrasonic vibration rotary digging machine, fixed bottom plate 29, counterweight 30, column 31, upper limit 32, main shaft lifting transmission chain device 33, ultrasonic generator and control box 34, lower limit 35, machine Frame 36, workbench 37 and rolling linear guide rail pair 38, the outer sleeve 20 of the ultrasonic vibration rotary digging machine is fixed on the fixed base plate 29, and the fixed base plate 29 is connected to the rolling linear guide rail pair set on the column 31 on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com