Double-ultrasonic-high-frequency induction combined precision micro-connection device and method

A high-frequency induction and micro-connection technology, used in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve problems such as connection space limitations, reduce space limitations, avoid incomplete removal of insulating layers, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

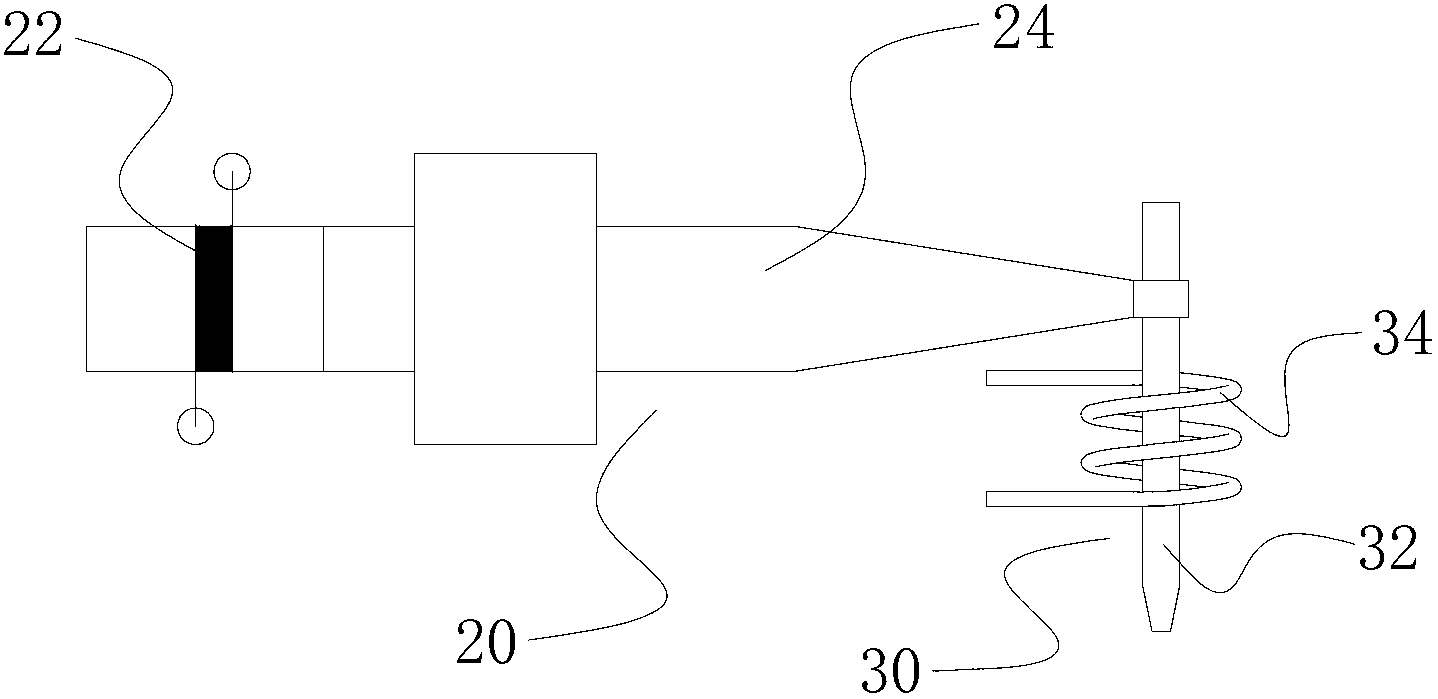

[0064] Such as Figure 1 to Figure 7 As shown, a double ultrasonic-high frequency induction composite precision micro-connection method, the specific implementation steps are as follows:

[0065] (1) Start the power supply, and preset the connection parameters according to the material and size of the workpiece to be connected;

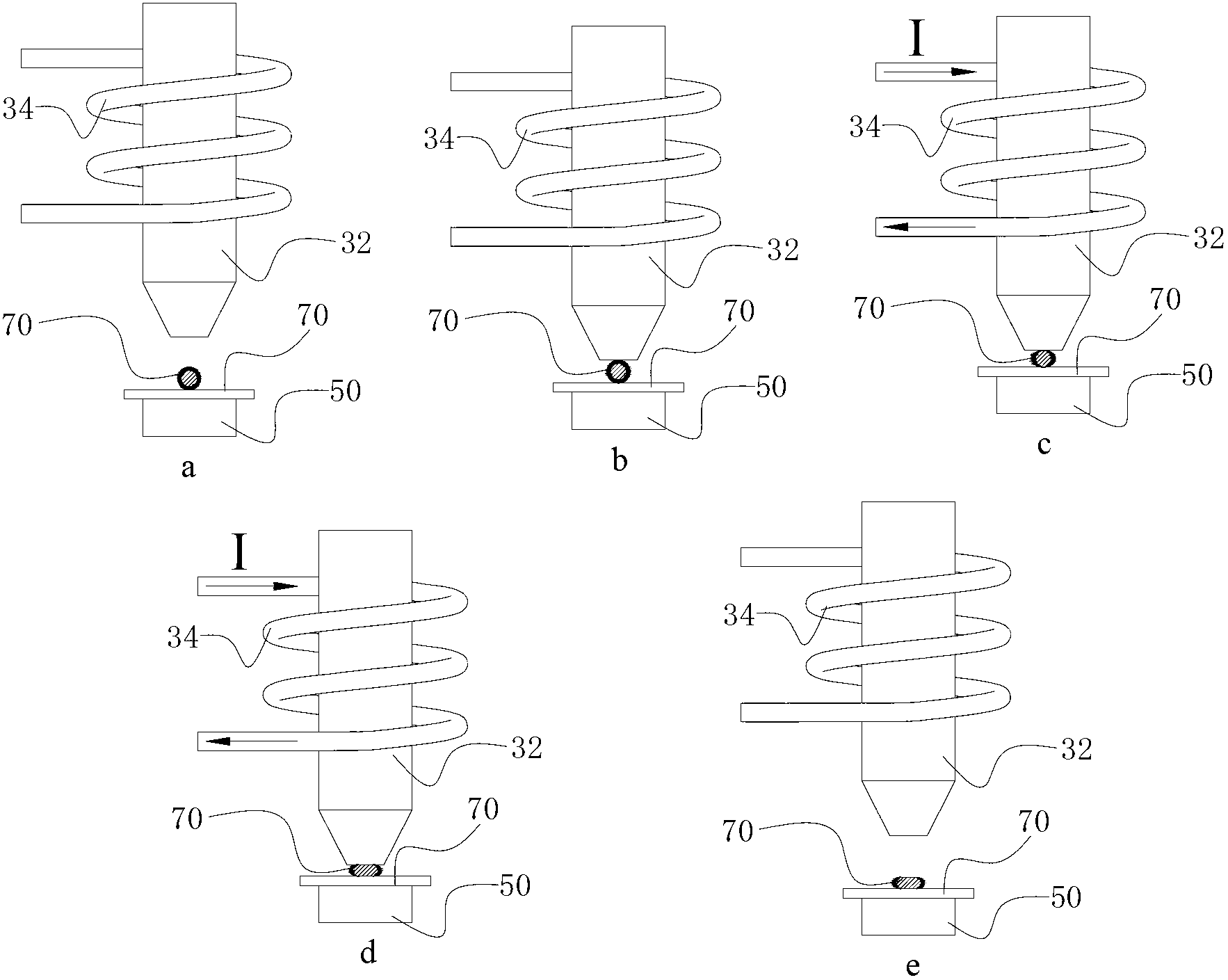

[0066] (2) Place the workpiece to be connected between the high-frequency induction self-heating head of the connection device and the worktable; ( image 3 a)

[0067] (3) The high-frequency induction self-heating head starts to descend from the initial position, and presses the workpiece to be connected with a predetermined pressure; ( image 3 b)

[0068] (4) When the pressure reaches the preset value, trigger the control end of the upper ultrasonic vibration system and high-frequency induction self-heating device, respectively make the ultrasonic vibration system and high-frequency induction self-heating head work, and input heat energy to the ...

Embodiment 2

[0084] In this embodiment, except for the following features, other structures and processes are the same as in Embodiment 1: the pressurization method is pneumatic pressurization.

[0085] In the step (1), the workpieces to be connected are aluminum wires and aluminum sheets respectively.

[0086] In the step (1), press Figure 8 The work shown requires preset connection parameters, the preset pressurization mode is the secondary loading mode, and the ultrasonic loading mode is the constant amplitude loading mode.

[0087] In the step (4), when the pressure reaches the preset value, the control terminals of the upper and lower ultrasonic vibration systems and the high-frequency induction self-heating device are triggered, and heat energy and two beams of ultrasonic waves are input to the joint to be connected to realize the control of the workpiece. Precision micro-joints. In this example, combined with Figure 8 pair connection phase (t 1 -t 4 ) are specified as follows...

Embodiment 3

[0092] In this embodiment, except the following features, other structures and processes are the same as in Embodiment 2:

[0093] In the step (1), press Figure 9 The work shown requires preset connection parameters.

[0094] In the step (4), when the pressure reaches the preset value, the control terminal of the upper ultrasonic vibration system and the high-frequency induction self-heating device is triggered, and heat energy and ultrasonic waves are input to the joint to be connected to realize precise micro-connection of the workpiece. In this example, combined with Figure 9 For the time period t in the connection phase 3 -t 5 The specific instructions are as follows:

[0095] time period t 3 -t 4 : Enter the secondary loading stage, the pressure increases to F 2 . with t 1 -t 3 After the connection work is completed, the contact area becomes larger and larger, and the joint is basically formed.

[0096] time period t 3 -t 4 : The ultrasonic vibration system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com