Directional sowing device for long seeds

A seeding device and a seeding device technology, applied in the direction of spaced quantitative sowing machinery, seeder parts, etc., can solve the problem of low seeding efficiency and achieve the effect of improving seeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

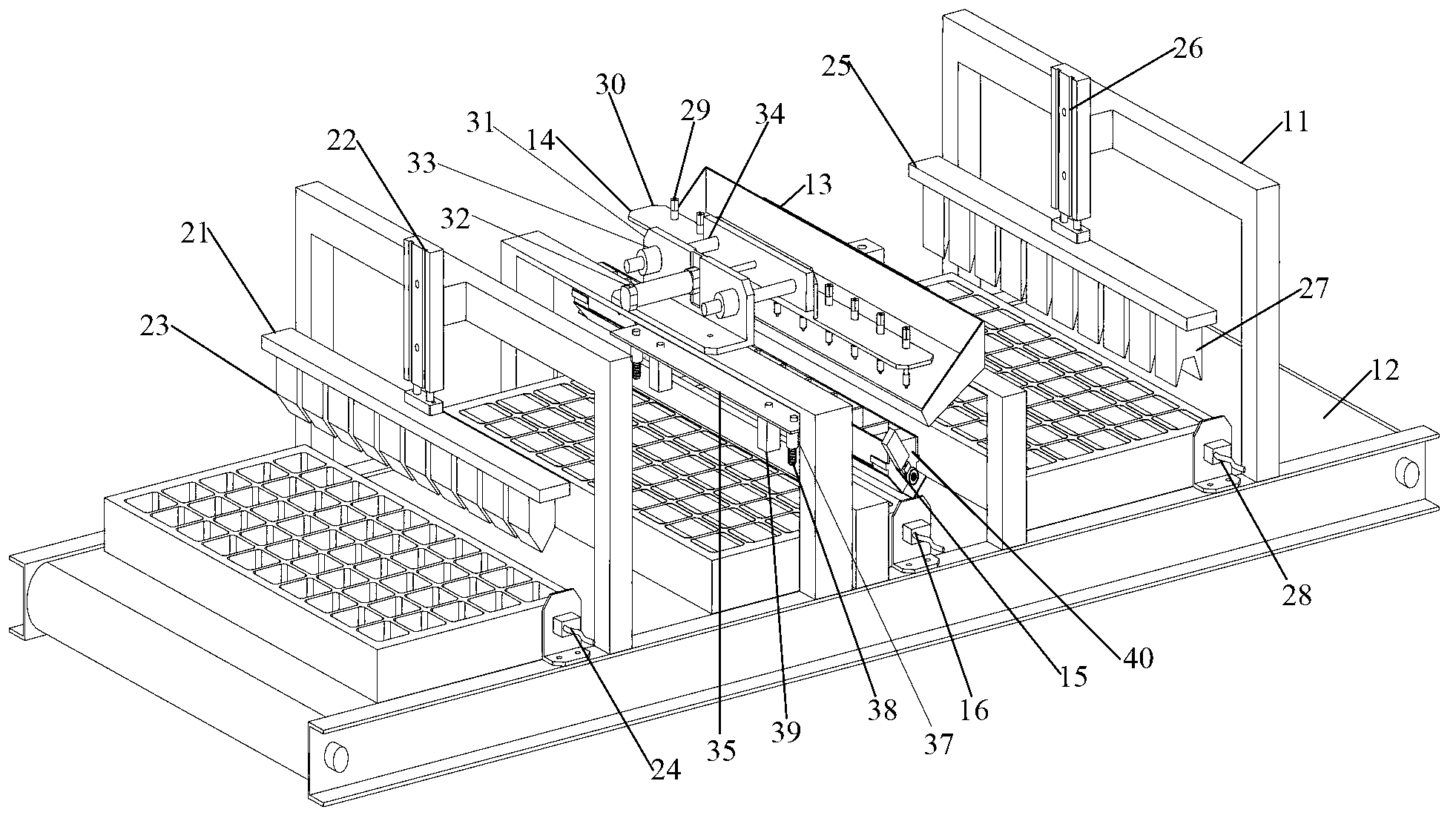

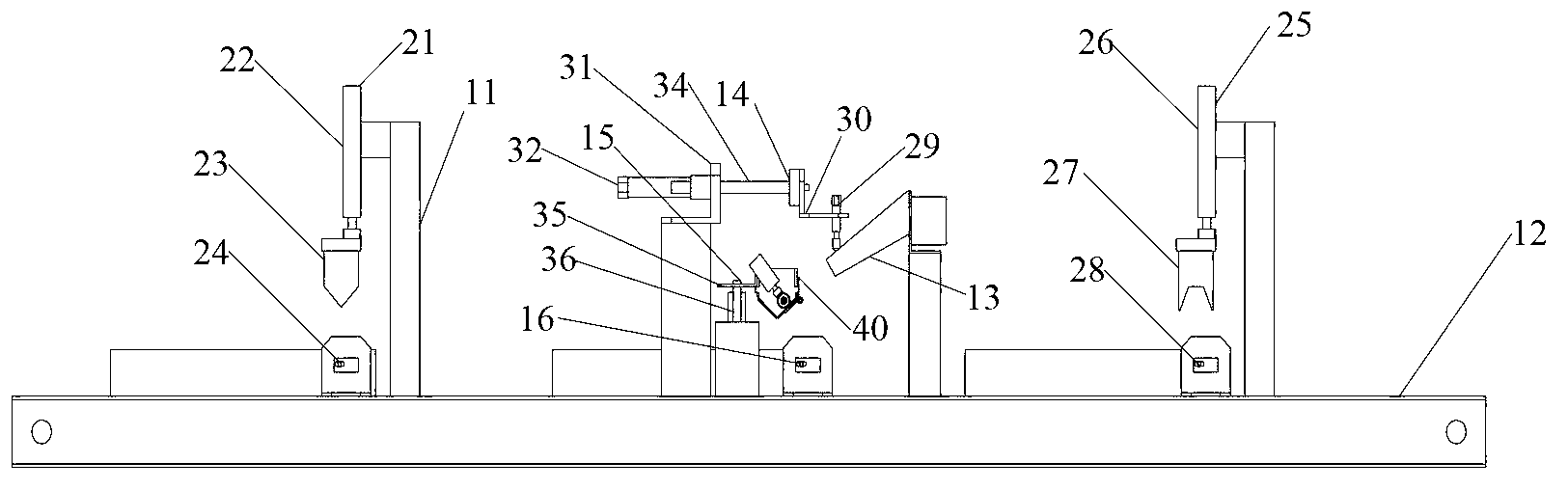

[0017] The technical solution of the present invention will be described in further detail below through specific embodiments and accompanying drawings.

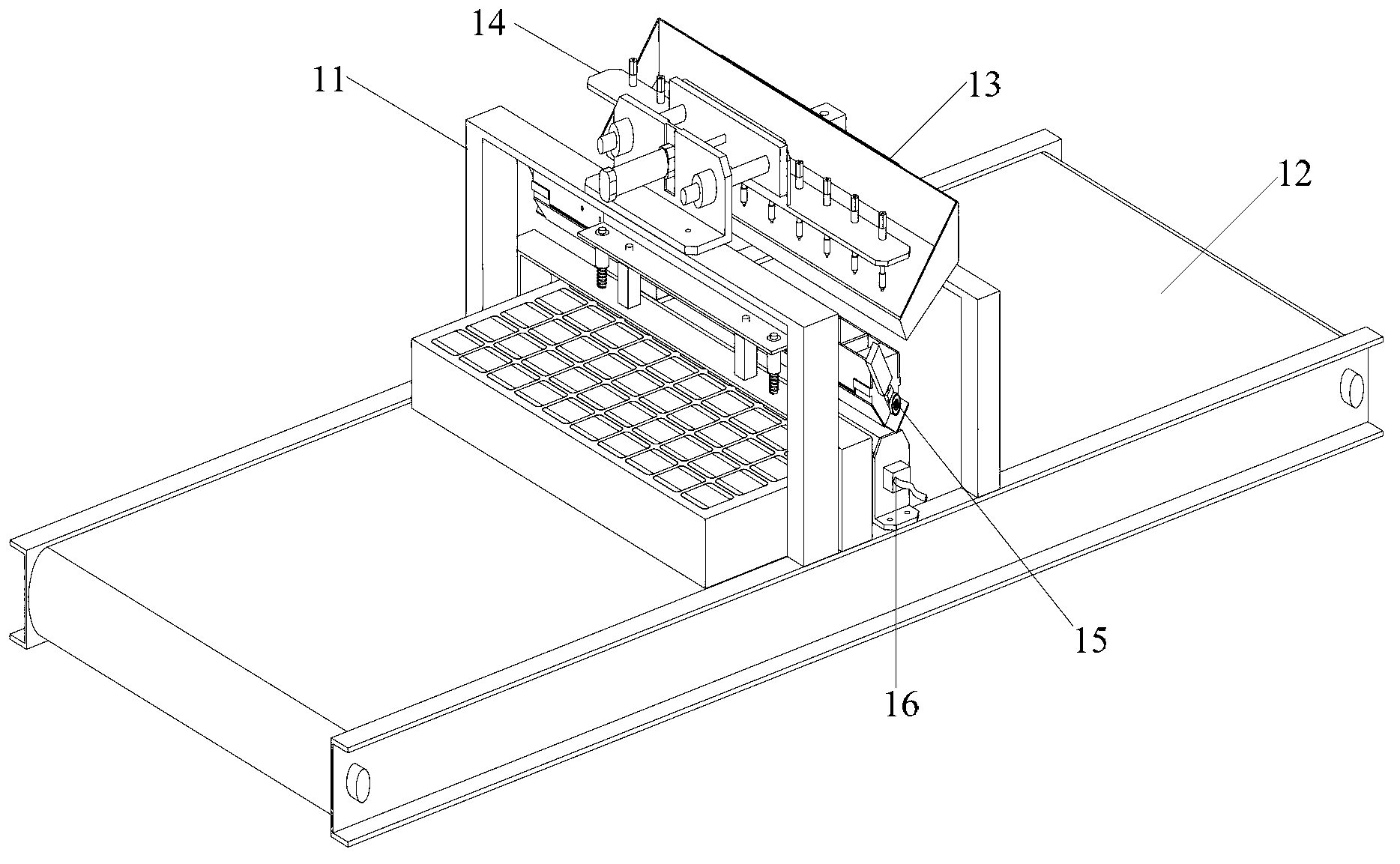

[0018] figure 1 It is a structural schematic diagram of an embodiment of the long-type seed directional sowing device provided by the present invention. Such as figure 1 Shown, this elongated seed directional sowing device can comprise: frame 11, tray conveyer belt 12, seed tank 13, suction and discharge seed device 14 and direction adjustment device 15, wherein:

[0019] The frame 11 is used to carry the tray conveyor belt 12;

[0020] The tray conveyor belt 12 is used to transfer the tray, and the tray includes multiple rows of holes;

[0021] The seed tank 13 is arranged on the frame 11 above the tray conveyor belt 12, and is used to hold long seeds to be sown;

[0022] The seed suction and discharge device 14 is arranged on the frame 11 above the tray conveyor belt 12, and is used to absorb a plurality of elongated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com