Seeding rate adjusting device for seed metering device

The technology of quantity adjustment and seed metering device, which is applied to the parts of the seeder, can solve the problems of low seeding efficiency, inconvenient use, high labor intensity, etc., and achieve the effects of high seeding efficiency, convenient operation, safe and reliable seeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

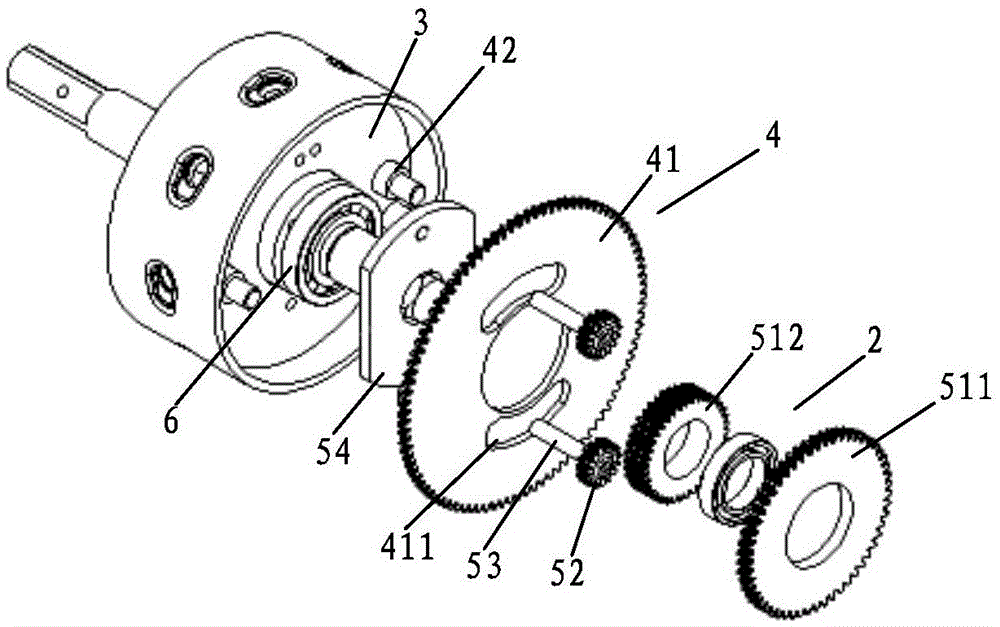

[0020] refer to figure 1 with figure 2 , the present embodiment relates to the sowing amount adjustment device of the seed meter, comprising a main shaft 1 and an outer hole wheel 2 rotatably mounted on the main shaft 1, an inner hole wheel 3, a rotation driving mechanism 4 and a locking mechanism 5, the outer hole The outer circumference of the wheel 2 is respectively provided with a through hole 21, and the outer circumference of the inner hole wheel 3 is provided with a groove 31 corresponding to the through hole 21, and the inner hole wheel 3 is rotatable and slidably sleeved. In the outer hole wheel 2; the rotation drive mechanism 4 is fixedly connected with the inner hole wheel 3, and the output end of the locking mechanism 5 can slide and press the inner hole wheel 3, and the inner hole wheel 3 It is fixedly connected with the outer hole wheel 2. During installation, the main shaft 1, the rotating drive mechanism 4 and the locking mechanism 5 are separately connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com