Internal combustion engine with injection valve

An engine and injection valve technology, applied in the direction of engine components, machines/engines, fuel injection devices, etc., can solve the problems of complexity, valve retention, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

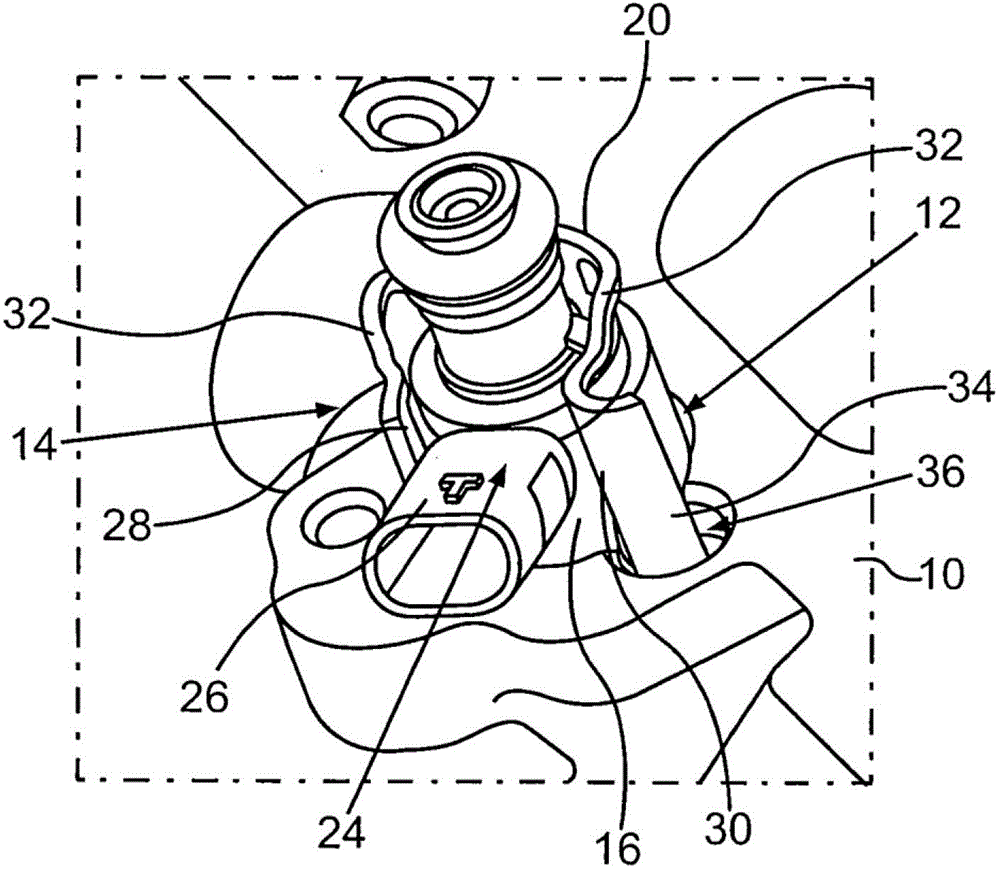

[0023] figure 1 A perspective view of a detail of a cylinder head 10 for an engine is shown. Cylinder head 10 has receiving bores 12 for injection valves 14 .

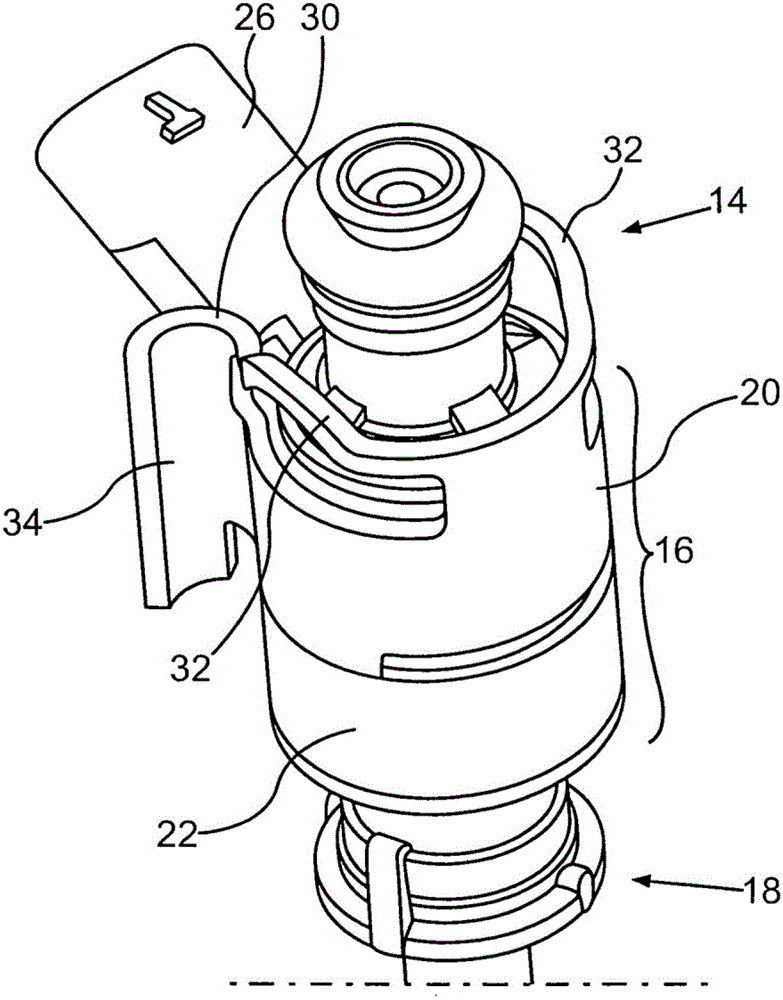

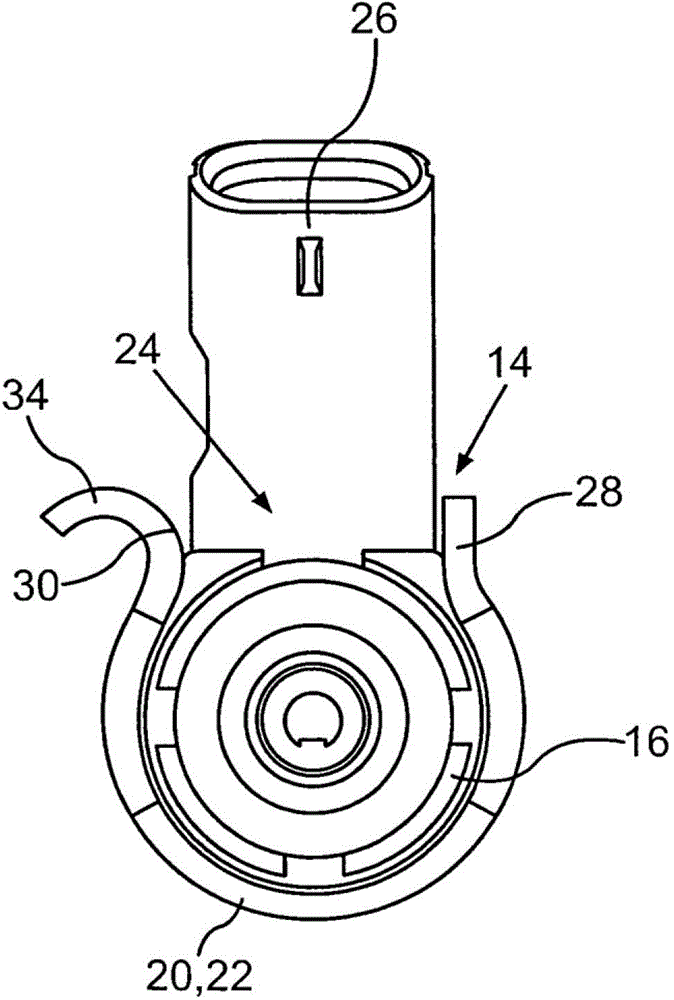

[0024] figure 2 Injection valve 14 , which is shown separately in perspective in FIG. 2 , is inserted with shank region 16 into receiving bore 12 , whereby it protrudes with its nozzle end 18 into the combustion chamber of the engine. Fuel can be injected under high pressure into the combustion chamber via injection valve 14 , which allows better mixture formation in the combustion chamber. In addition, the direct injection of fuel allows different mixing ratios to be produced in different regions of the combustion chamber, whereby it is achieved that the engine is operated at its optimum thermodynamic operating point and thus its efficiency is optimized.

[0025] In order to allow such a locally controlled mixture formation, precise positioning of the injection valve 14 in the receiving bore 12 is required. It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com