Capacitor bank trimming method and trimming system thereof

A capacitor bank and capacitor technology, applied in the field of capacitors, can solve problems such as low installation efficiency and difficulty in finding capacitor units, and achieve the effects of improving installation efficiency, ensuring integrity and accuracy, and ensuring overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

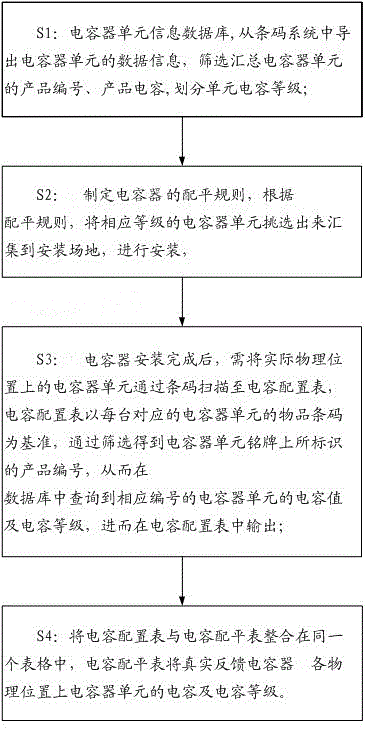

[0034] Such as figure 1 , the invention provides a method for balancing capacitor banks, comprising the steps of:

[0035] S1: Classify all capacitor units according to capacitance, and mark the capacitor units according to regulations;

[0036] The step S1 is specifically: the capacitor unit information database is established on the basis of the barcode data system, the data information of the capacitor unit is derived from the barcode system, and the product number and product capacitance of the capacitor unit are screened and summarized: identifying all available for assembly, Qualified capacitor units; comprehensively analyze the capacitance deviation, formulate unit classification benchmarks, and classify qualified products that can be used for assembly;

[0037] S2: Calculate the average capacitance value of all capacitor units, and formulate the trimming rules for capacitors;

[0038] The step S2 specifically includes: formulating capacitor trim rules; according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com