Automatic control electric furnace flue gas combustion settling chamber

A technology of burning settling chamber and flue gas, which is applied in the field of separation, which can solve the problems of many dead angles, unfavorable CO burnout, and no automatic control device, etc., and achieve the effect of avoiding CO accumulation, eliminating dead angles, and avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

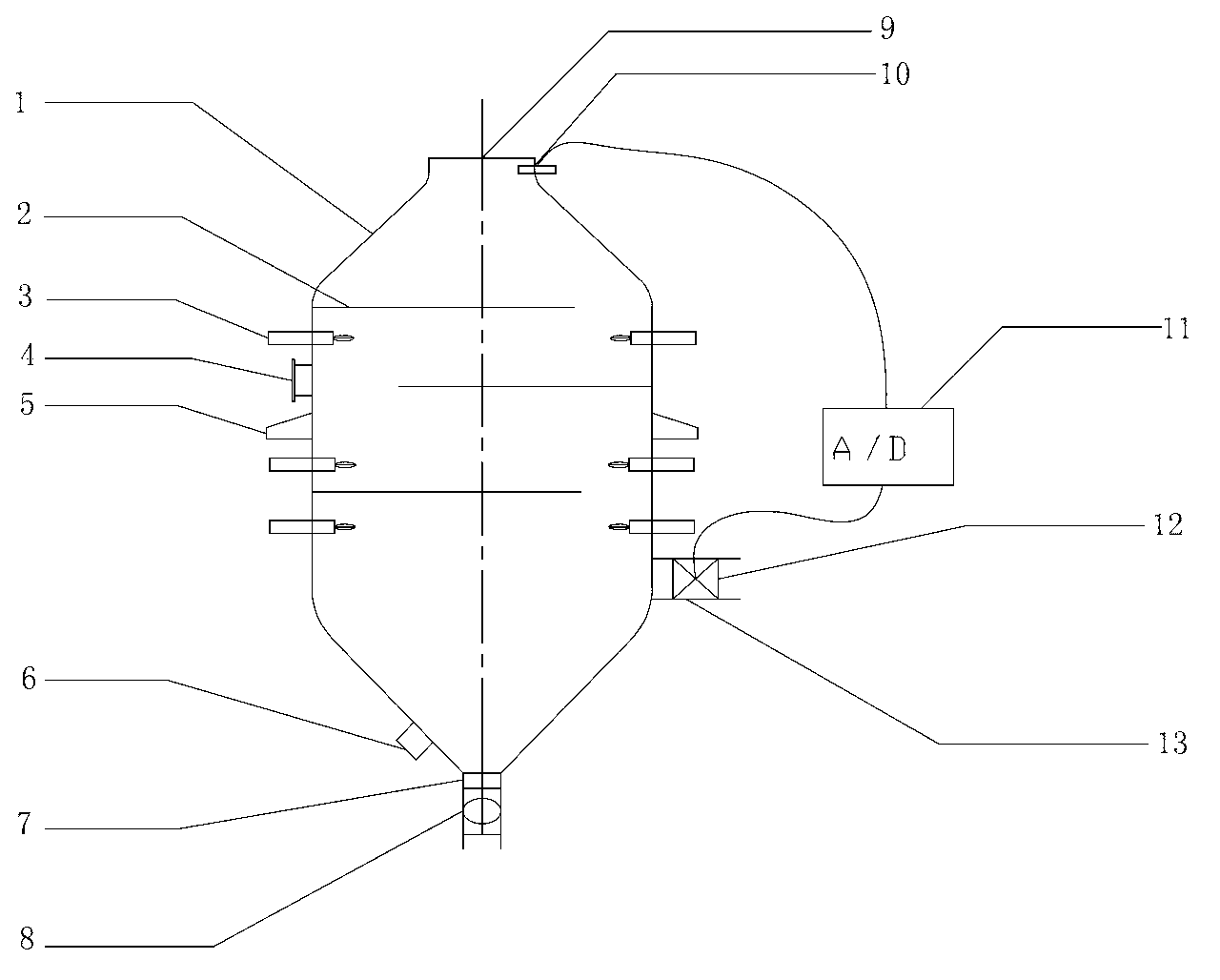

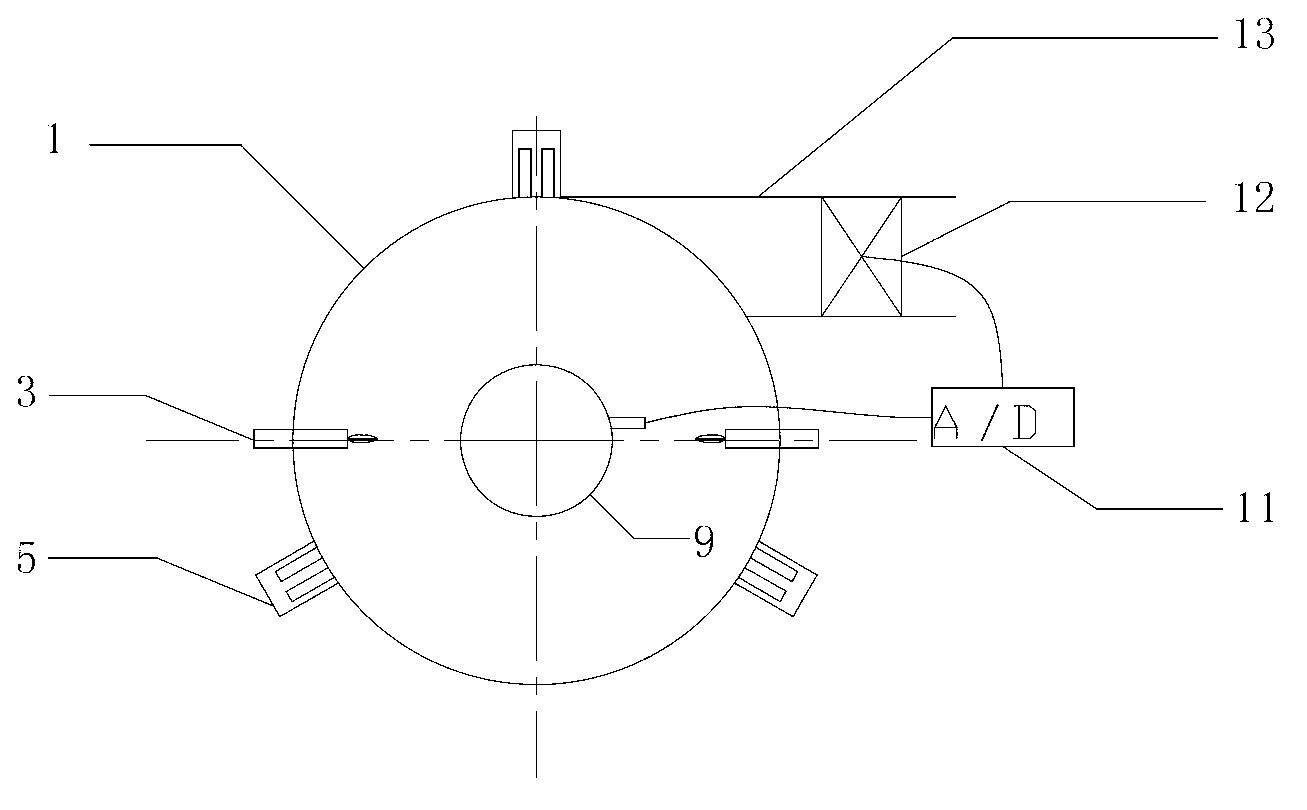

[0017] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 with figure 2 As shown, it is a structural schematic diagram of the present invention. The self-controlled electric furnace flue gas combustion settling chamber includes a shell 1, a baffle plate 2, a support 5, a burner 3, a flue gas inlet 13, a flue gas outlet 9, and an ash discharge port 7 , Rapper 6, CO concentration monitoring device 10 and A / D converter 11. The cross-section of the shell 1 is circular, which can effectively eliminate the dead angle existing in the shell of the traditional structure and avoid the phenomenon of CO accumulation. The shell 1 is provided with a maintenance manhole 4, and the upper and lower parts of the shell 1 are set as Taper structure, the inner wall of the shell is equipped with vaporization cooling coil or water-cooled heat exchange tube. When the vaporization cooling coil structure is adopted, it can absorb the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com