Internal-slat fixing device

A fixing device and shutter technology, applied in door/window protection devices, windows/doors, building components, etc., can solve problems such as failure of insulating glass, easy failure of butyl rubber, and reduced elasticity of grooved aluminum spacers, so as to prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

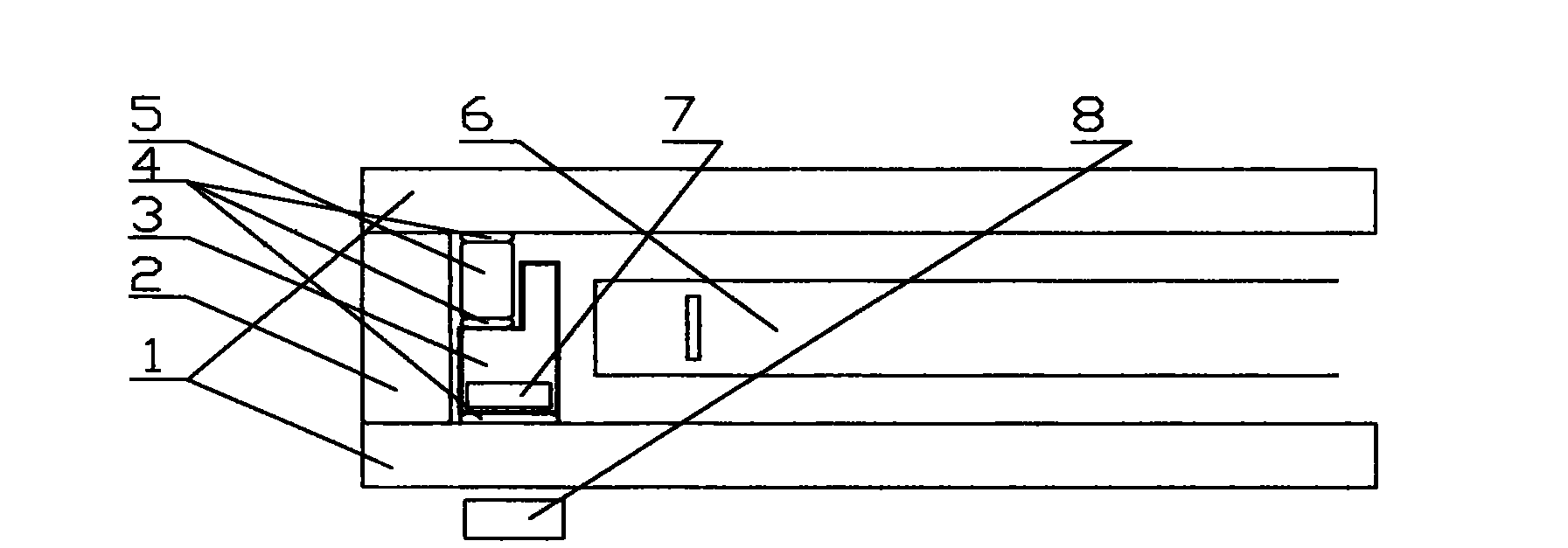

[0012] like figure 1 The elastic rubber strip embodiment shown is embodiment 1, figure 1 The built-in louver 3 is glued on the glass 1 by the inner layer glue 4, the elastic rubber strip 5 is glued on the glass 1 by the inner layer glue 4 on one side, and the other side is glued on the built-in louver 3 by the inner layer glue 4. The outer layer of glue 2 is sealed, the louver 6 and the built-in magnet 7 are part of the built-in louver 3, and the magnetic control handle 8 is on the outer surface of the insulating glass.

Embodiment 2

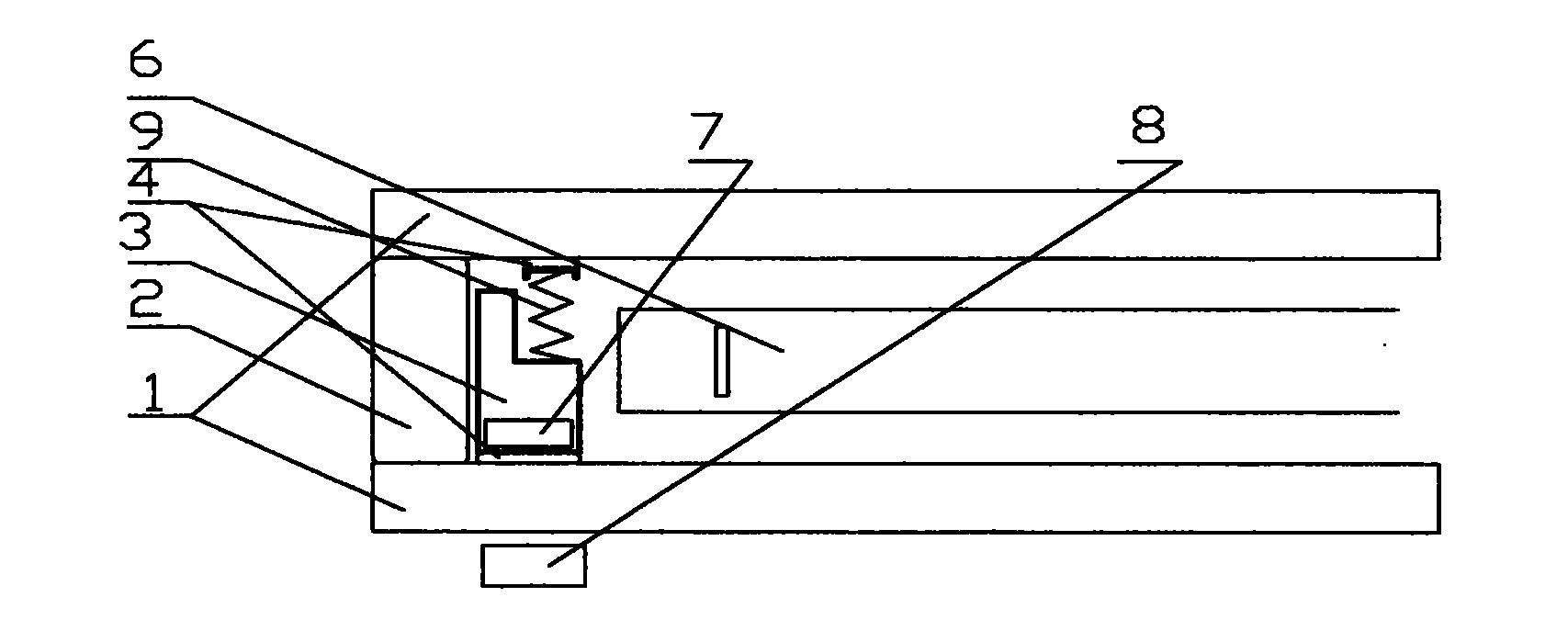

[0014] like figure 2 The spring embodiment shown is Embodiment 2, figure 2 The built-in louver 3 is glued to the glass 1 by the inner layer glue 4, the spring 9 is glued to the glass 1 by the inner layer glue 4 on one side, and the other side is fixed on the built-in louver 3, and the surrounding is sealed with the outer layer glue 2. The louver 6 And the built-in magnet 7 is a part of the built-in shutter 3, and the magnetic control handle 8 is on the outer surface of the insulating glass.

Embodiment 3

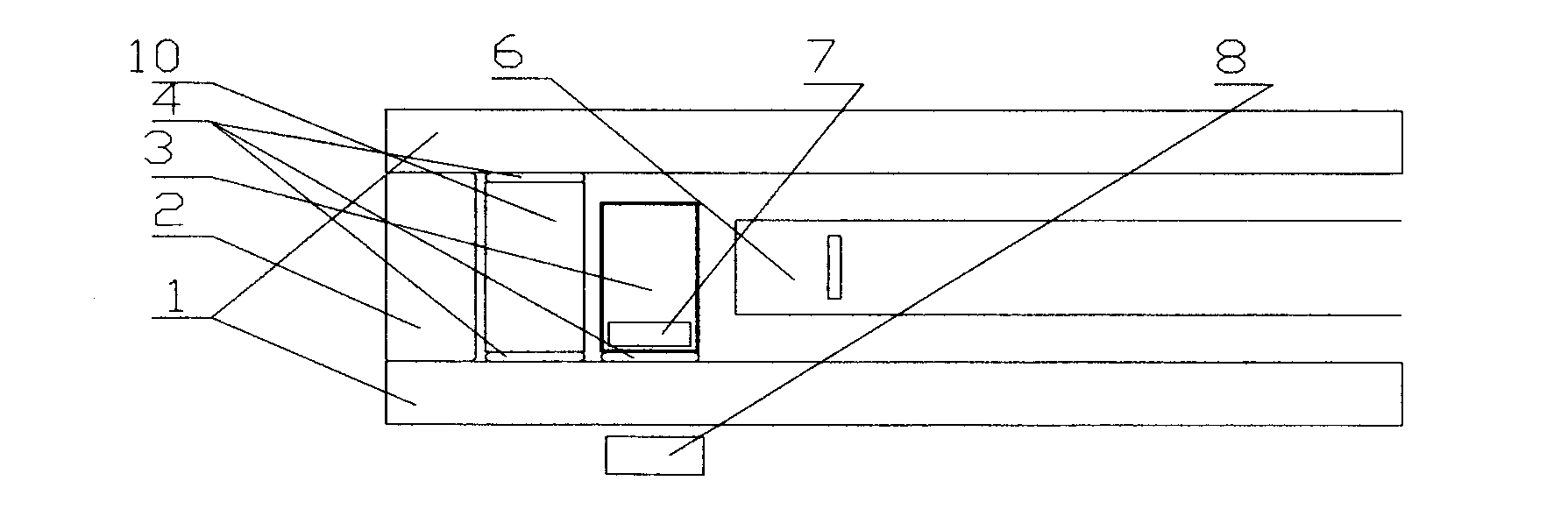

[0016] like image 3 The spacer bar embodiment shown is Embodiment 3, image 3 The built-in louver 3 is glued to the glass 1 by the inner layer glue 4, the spacer 10 is glued to the glass 1 by the inner layer glue 4, and the surrounding is sealed with the outer layer glue 2, the louver 6 and the built-in magnet 7 are built-in louver 3. In part, the magnetic control handle 8 is on the outer surface of the insulating glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com