Building assembled with prefabricated space frame substructures and construction method thereof

A technology of frame sub-structure and beam sub-structure, applied in the direction of building structure, construction, etc., can solve the problems of reducing construction efficiency, the integrity and reliability of dry method connection is not as good as wet method, and the construction quality of the joint is difficult to guarantee, etc., and achieves rapid construction. , Simplified design and production process, good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The patent of the present invention proposes a house assembly construction method based on a large prefabricated space frame substructure, and its specific implementation process and method will be further described in conjunction with the accompanying drawings.

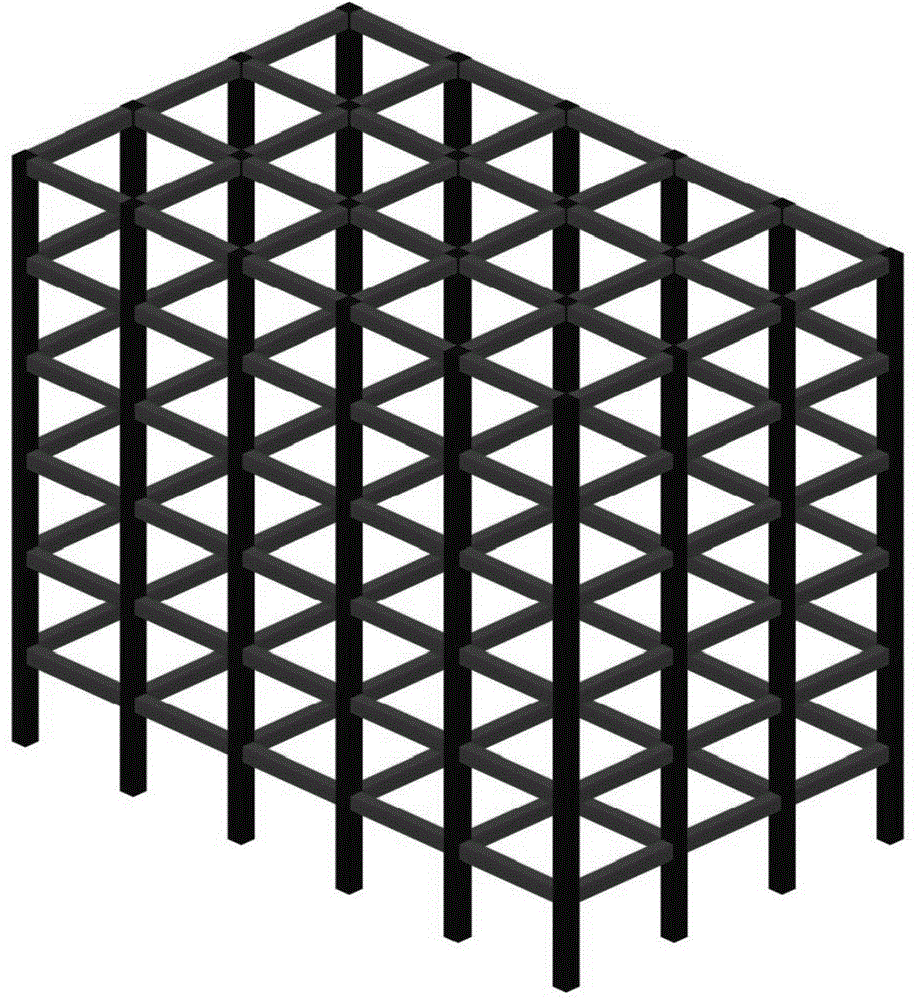

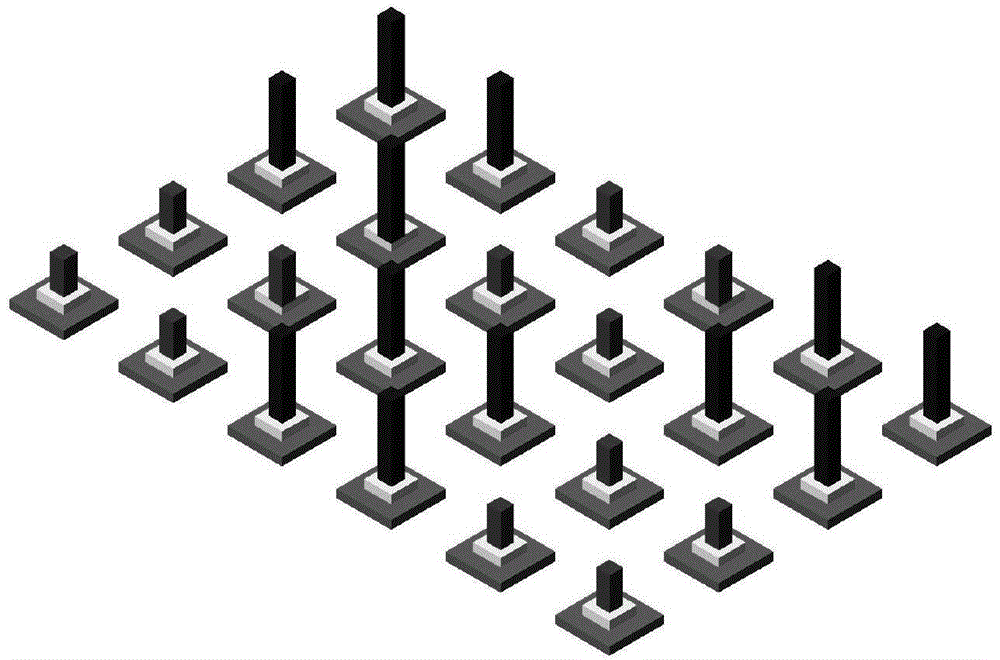

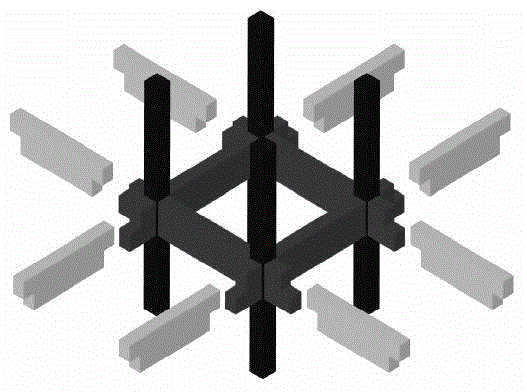

[0050] A building assembled from prefabricated space frame substructures includes a building foundation, multiple types of prefabricated space frame substructures and prefabricated beam substructures. The single-layer prefabricated space frame substructure is composed of four horizontal ring-shaped closed beams in the middle , four columns at the upper part of the beam node, four columns at the lower part of the beam node and multiple horizontal cantilevered short beams around the beam node, considering the vertical and horizontal expansion at the same time, the prefabricated space frame substructure is double-layered and one-way Two-span and two-way two-span prefabricated space frame substructure, the prefabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com