Composite steel capable of conveniently recovering core material and recovering method of composite steel

A technology of composite steel and core material, applied in sheet pile walls, layered products, construction, etc., can solve the problems of leftover rods, waste of materials, construction obstacles of buildings, etc., to reduce frictional resistance, and the recycling method is simple and convenient. The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] detailed description

[0020] The present invention will be explained below with reference to the drawings.

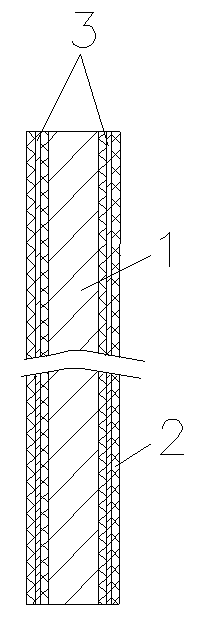

[0021] Such as figure 1 Shown is a composite steel material capable of easily recovering core material according to the present invention, comprising a steel body and a fusible wrap layer 2; the fusible wrap layer 2 is arranged on the outside of the steel body and tightly wraps the steel The body; the fusible wrap 2 is provided with an electric heating device 3; in this embodiment, the steel body is a steel bar 1; of course, the steel bar body can also be a steel pipe, a steel strand, or a section steel; The fusible wrap layer 2 is made of epoxy resin or plastic or wax or nylon. Of course, the electric heating device 3 can also be arranged on the inner side wall or the outer side wall of the fusible wrap layer 2.

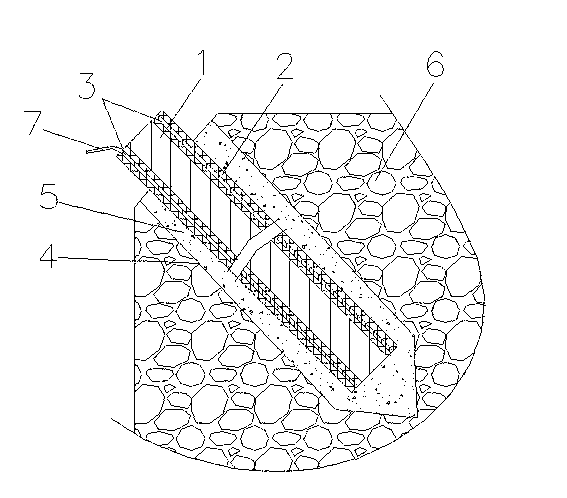

[0022] Such as figure 2 Shown is a schematic diagram of the application state of a composite steel material capable of easily recovering core materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com