Active green guardrail support

A support and guardrail technology, applied to roads, road safety devices, roads, etc., can solve problems such as easy overturning, achieve the effect of lowering the center of gravity, convenient assembly and use, and increasing green space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

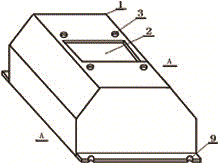

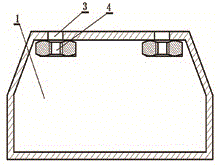

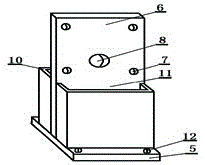

[0020] Example 1: see figure 1 , figure 2 , image 3 , Figure 4 , the active greening guardrail support, including a base and a vertical support 6, is characterized in that: the base and the vertical support 6 are made of steel plates, the vertical support 6 is perpendicular to the base, and the base is Hollow box body 1, hollow box body 1 is made up of top surface and bottom surface and surrounding wall surface, hollow box body 1 top surface is provided with Unicom hollow box body 1 inside and outside through window 2, and there are four connecting through holes 3 near the through window 2, Each connection through hole 3 is welded with a connection nut 4, and the connection nut 4 is on the inner top surface of the hollow box body 1, and the connection through hole 3 is larger than the nominal size of the connection nut 4. The beneficial effect is to obtain materials locally. The box is filled with high-density materials, such as building waste, which greatly reduces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com