Turnout device for monorail crane in coal mine and moving method of turnout device

A monorail crane and turnout technology, which is applied to the latching mechanism for turnouts, rails, and hydraulic equipment for operating turnouts or line breakers, etc., can solve the problems of rusting of sliding fulcrums and inability to perform normal direction change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

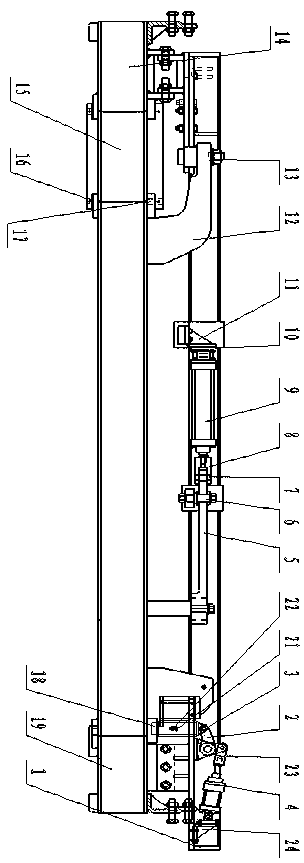

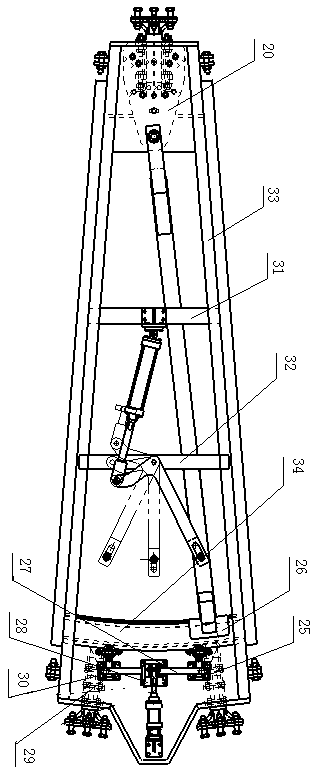

[0014] Embodiment one: figure 1 , figure 2 As shown, this embodiment includes a frame 33, a swing rail 12, a rail entry 19, and a rail exit 14. One end of the swing rail 12 is connected to the frame 33 through a bearing, and the other end is arranged on a slideway 34 through a bearing 26 and driven by the cylinder 9 to swing , the slideway 34 is arc-shaped.

[0015] The frame 33 is a trapezoidal frame, with lifting lugs welded on the frame 33, and the lifting lugs are connected with the mine roadway bolt through the lifting rings; the frame 33 is provided with reinforcing ribs (ie short beams 31 and long beams 32).

[0016] The cylinder liner at one end of the cylinder 9 is installed on the short beam 31 of the frame 33, and the piston rod at the other end is connected with one end of the crank arm 5. The middle of the crank arm 5 is arranged on the long beam 32 of the frame by a bearing pin. The other end is connected with the swing rail 12 .

[0017] There are two entry ...

Embodiment 2

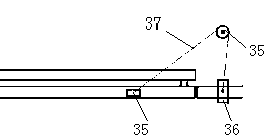

[0021] Embodiment two: image 3 , Figure 4 As shown, the locking mechanism of the present embodiment includes a rail clamp 36, a steel strand 37, and a fixed pulley 35. And steel strand 37 is connected with swing rail 12, and when swing rail 12 swings to a side of track, the rail clamp device 36 of this side is opened, and the rail clamp device locking of the other side prevents driver's misoperation from causing crash accident to take place.

[0022] Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com