Pit sealing method

A cellar and sealing cover technology, applied in the field of cellar sealing, can solve the problems of bacteria pollution, inconvenient operation, loss of water dispersion, etc., and achieve the advantages of easy processing, manufacturing and installation, convenient processing and use, and improved resistance to deformation effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

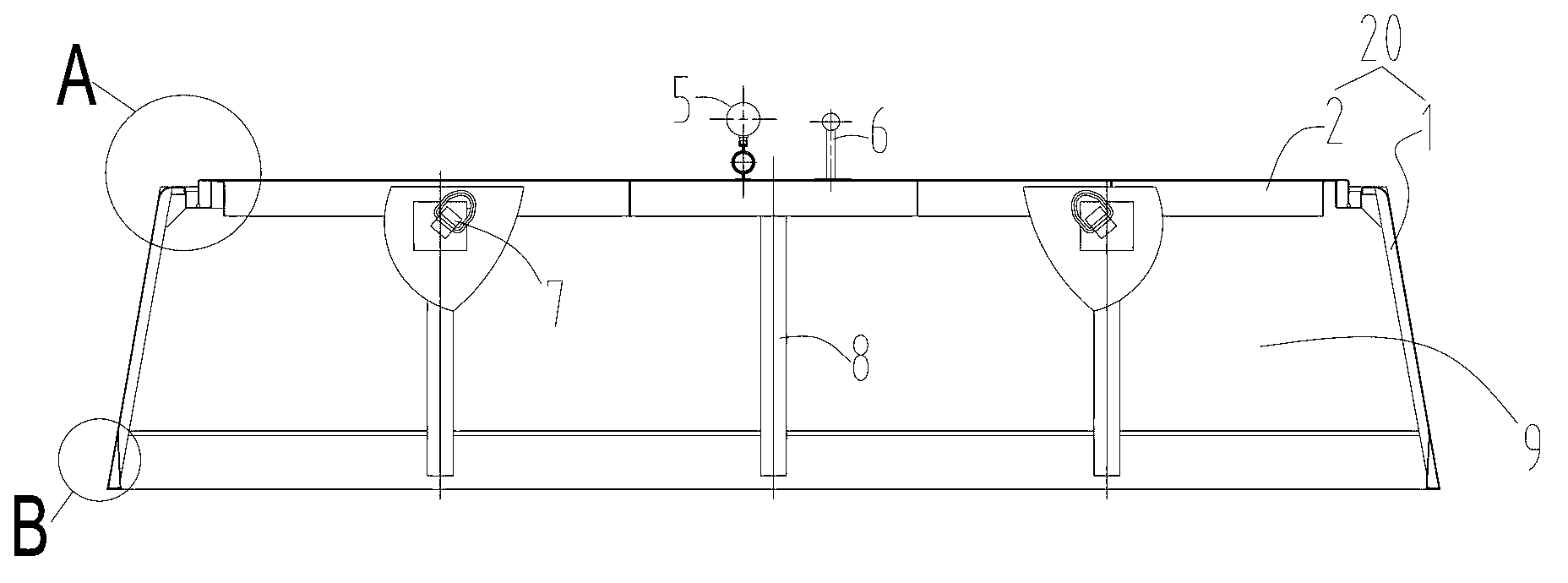

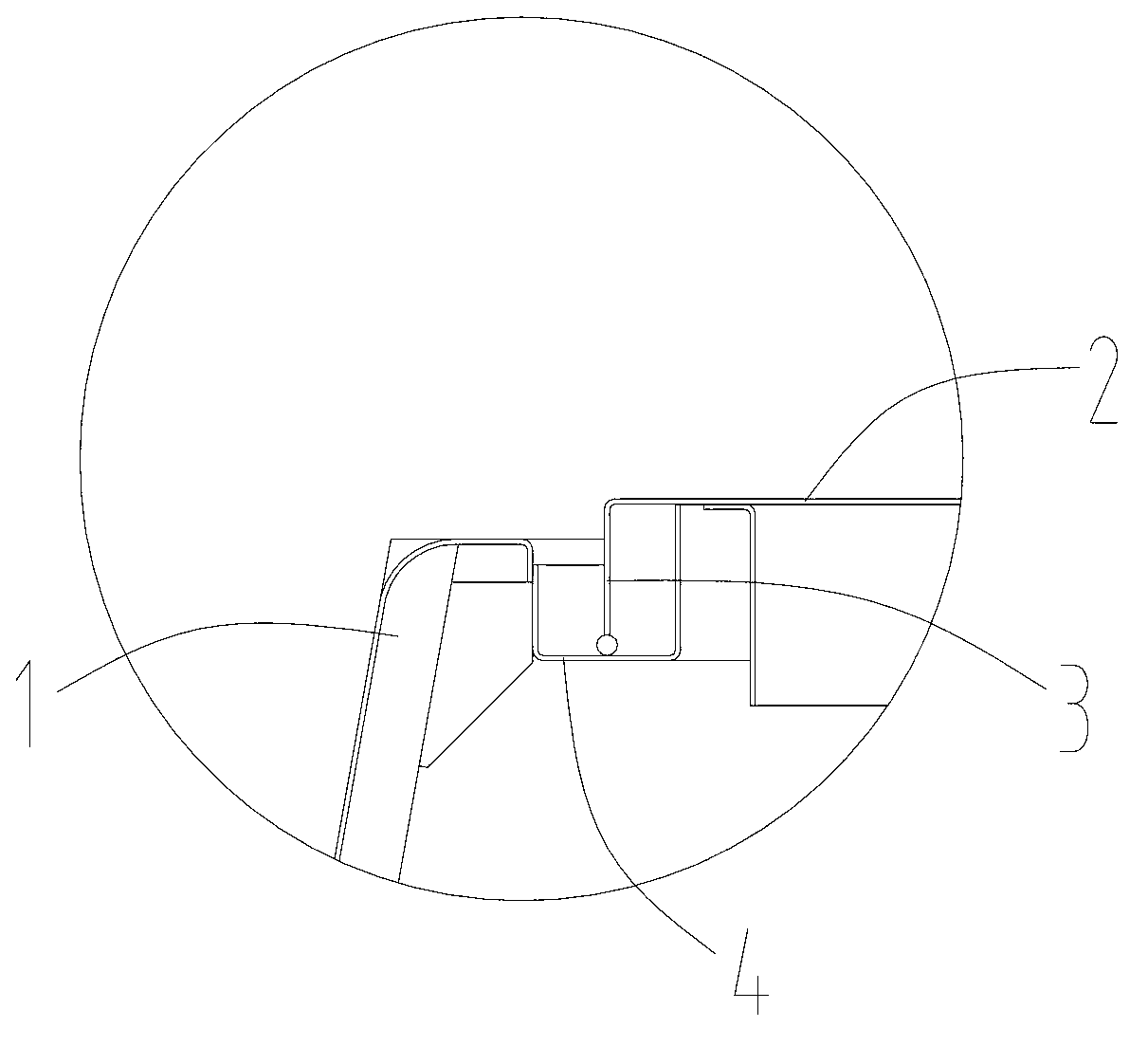

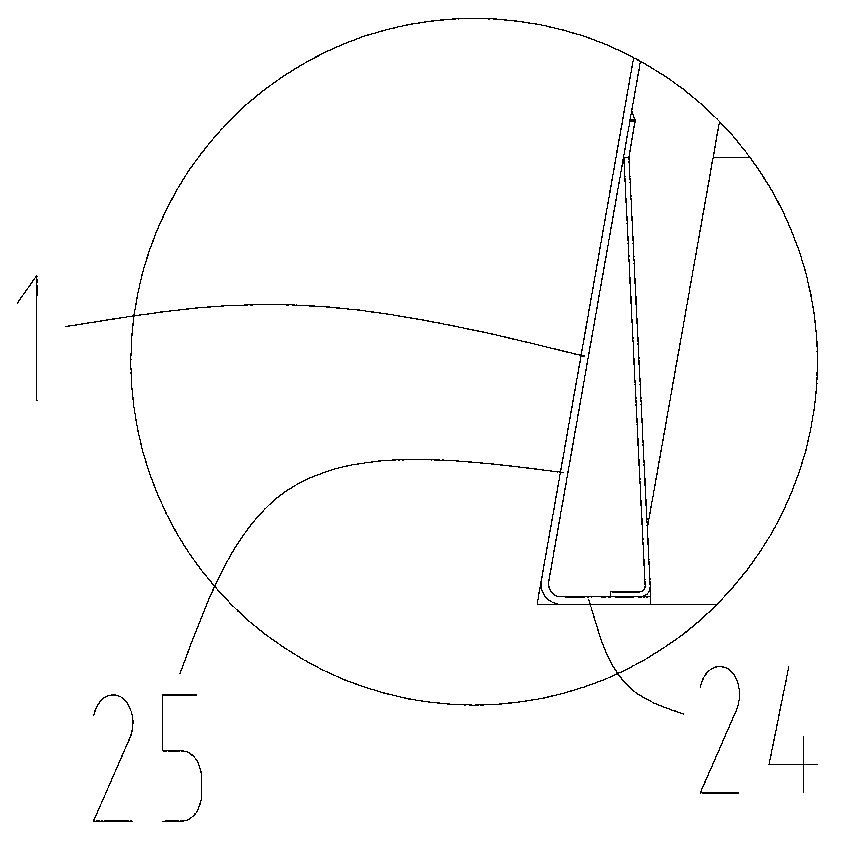

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0053] Such as Figure 9 As shown, in the cellar sealing method of the present invention, the cellar 18 is sealed by the sealing cover 20, and the sealing cover 20 is provided with an exhaust device for discharging the gas in the sealing cover. The traditional method of sealing the cellar is generally to seal a certain thickness of mud on the surface of the surface of the cellar after the grains are poured into the full cellar. Because the mud is greatly affected by environmental factors, the seal will dry out and crack, resulting in poor sealing. However, the present invention adopts the sealing cover 20 to seal the cellar 18, which can effectively seal the fermented grains at the top of the cellar, and provide the environment required for anaerobic fermentation for the microbes of the fermented grains. Moreover, the sealing cover 20 is not g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com