Nutrient restoration agent of organic activity desertification soil and preparation method thereof

A technology of desertification soil and remediation agent, applied in the field of soil remediation, can solve problems such as poor popularization and wide practicability, and achieve the effect of lasting water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 The manufacture of the solid module restoration agent of the present invention

[0045] The raw materials of this embodiment are: 40 parts of peat humic acid, 3 parts of binder, 30 parts of water-retaining agent, 1.5 parts of nitrogen fertilizer, 1.2 parts of phosphate fertilizer, and 0.3 part of potassium fertilizer.

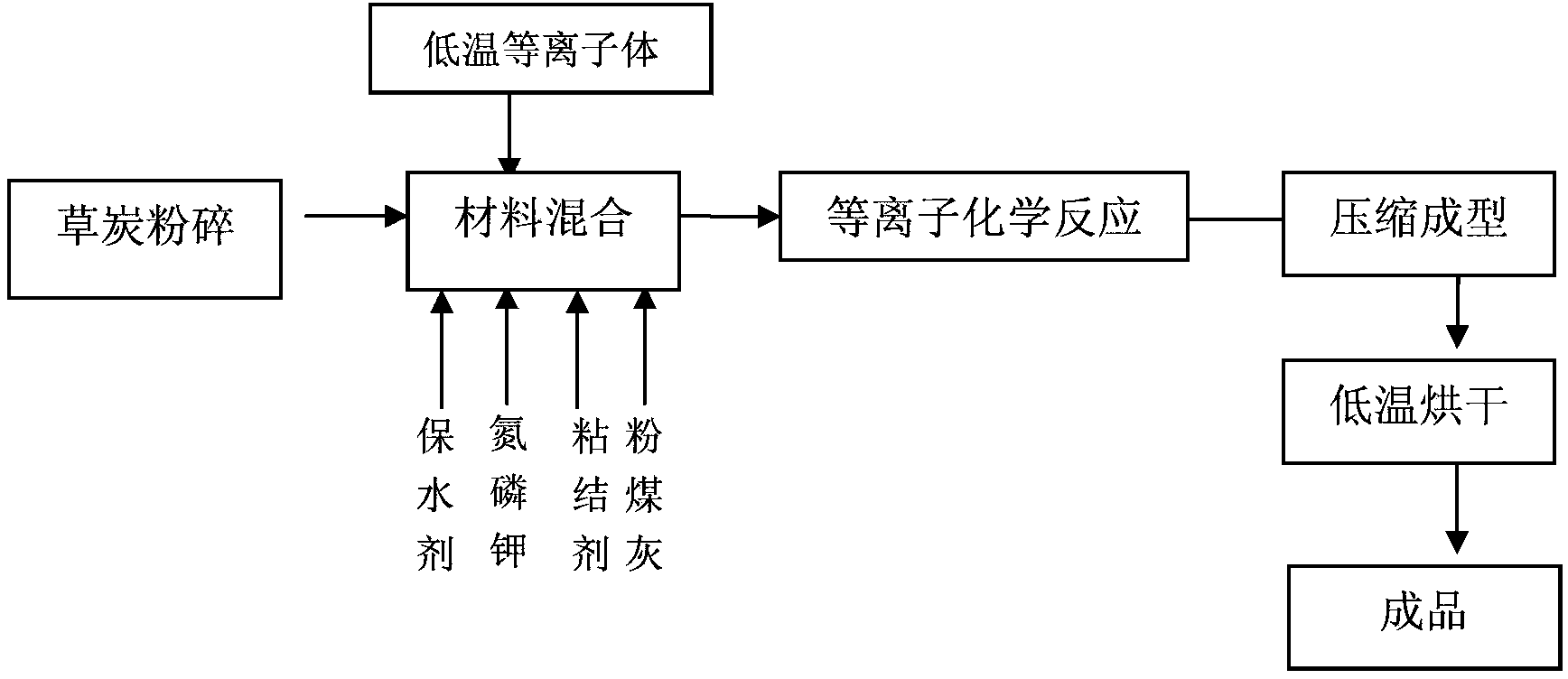

[0046] refer to figure 1Carry out the manufacture of solid module restoration agent of the present invention:

[0047] 1) Crush the peat and add other raw materials in proportion to obtain mixed raw materials;

[0048] 2) Put the mixed raw materials described in step 1) into the low-temperature plasma, and carry out the plasma chemical reaction for 1 minute;

[0049] 3) The mixed raw materials after the plasma chemical reaction are compression-molded with a length of 8 cm, a width of 8 cm, and a height of 3 cm, and dried at a low temperature of 70-80 ° C to obtain a solid module repair agent.

Embodiment 2

[0050] Embodiment 2 Manufacture of solid module restoration agent of the present invention

[0051] The raw materials of this embodiment are: 60 parts of peat humic acid, 1 part of binder, 10 parts of water-retaining agent, 1.5 parts of nitrogen fertilizer, 1.2 parts of phosphate fertilizer, and 0.3 part of potassium fertilizer.

[0052] refer to figure 1 Carry out the manufacture of solid module restoration agent of the present invention:

[0053] 1) Crush the peat and add other raw materials in proportion to obtain mixed raw materials;

[0054] 2) Put the mixed raw materials described in step 1) into the low-temperature plasma, and carry out the plasma chemical reaction for 3 minutes;

[0055] 3) The mixed raw materials after the plasma chemical reaction are compression-molded with a length of 8 cm, a width of 8 cm, and a height of 3 cm, and dried at a low temperature of 70-80 ° C to obtain a solid module repair agent.

Embodiment 3

[0056] Embodiment 3 Manufacture of the liquid coating restoration agent of the present invention

[0057] The raw materials of this embodiment are: 30 parts of weathered coal humic acid, 30 parts of cellulose, 1 part of film-forming agent, 30 parts of microbial strains, 0.7 part of nitrogen fertilizer, 0.5 part of phosphate fertilizer, and 0.1 part of potassium fertilizer.

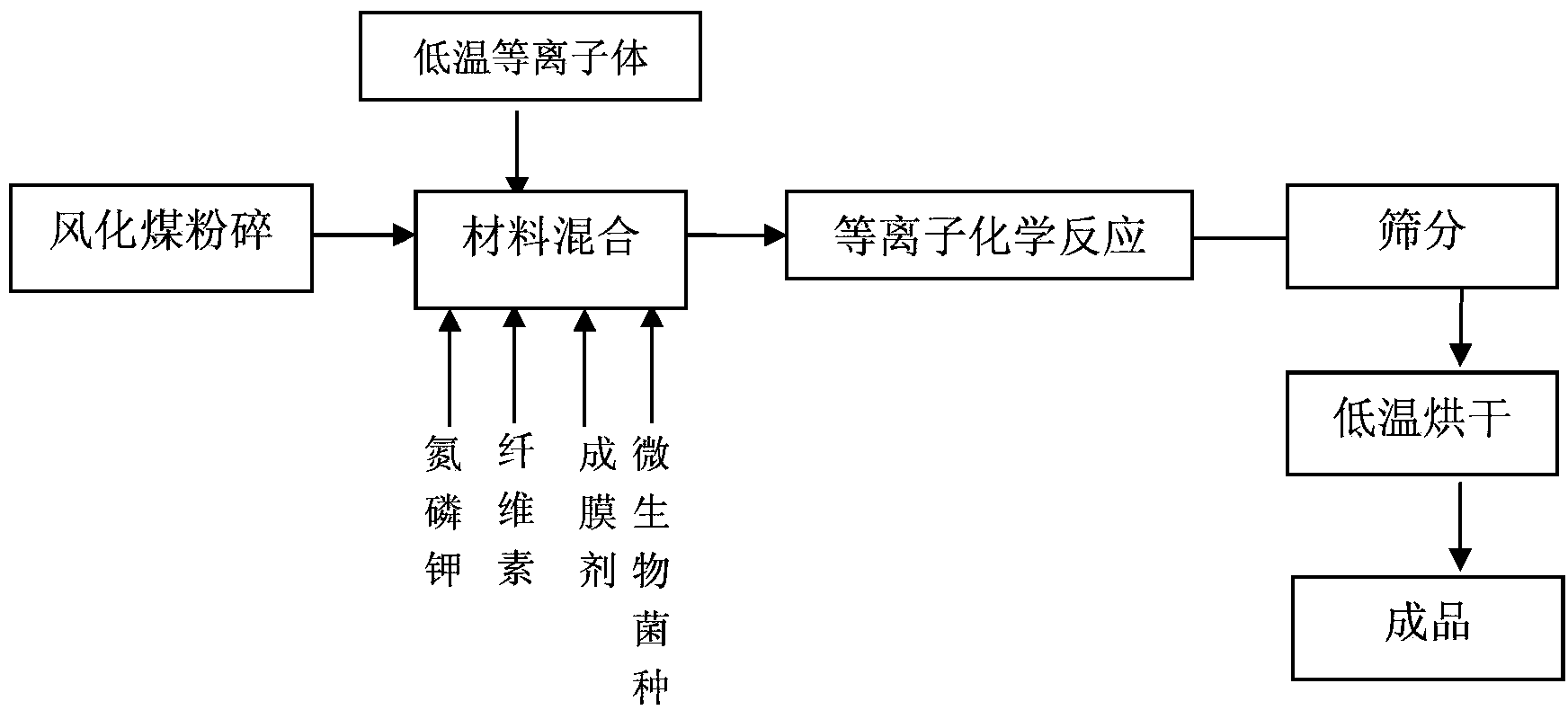

[0058] refer to figure 2 Carry out the manufacture of liquid covering restoration agent of the present invention:

[0059] 1) Grinding active humic acid, adding other raw materials in proportion to obtain mixed raw materials;

[0060] 2) Put the mixed raw materials described in step 1) into the low-temperature plasma, and carry out the plasma chemical reaction for 2 minutes;

[0061] 3) After sieving the mixed raw materials after the plasma chemical reaction to remove particles with a particle size of more than 1 micron, dry them at a low temperature of 70-80°C to obtain a liquid coating repair agent. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com