Pulp distributer

A distributor and pulp technology, applied in liquid distribution, distribution devices, special distribution devices, etc., can solve the problems that the secondary uniform distribution of the pulp cannot be achieved, and it is difficult to evenly distribute the pulp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0022] This example includes:

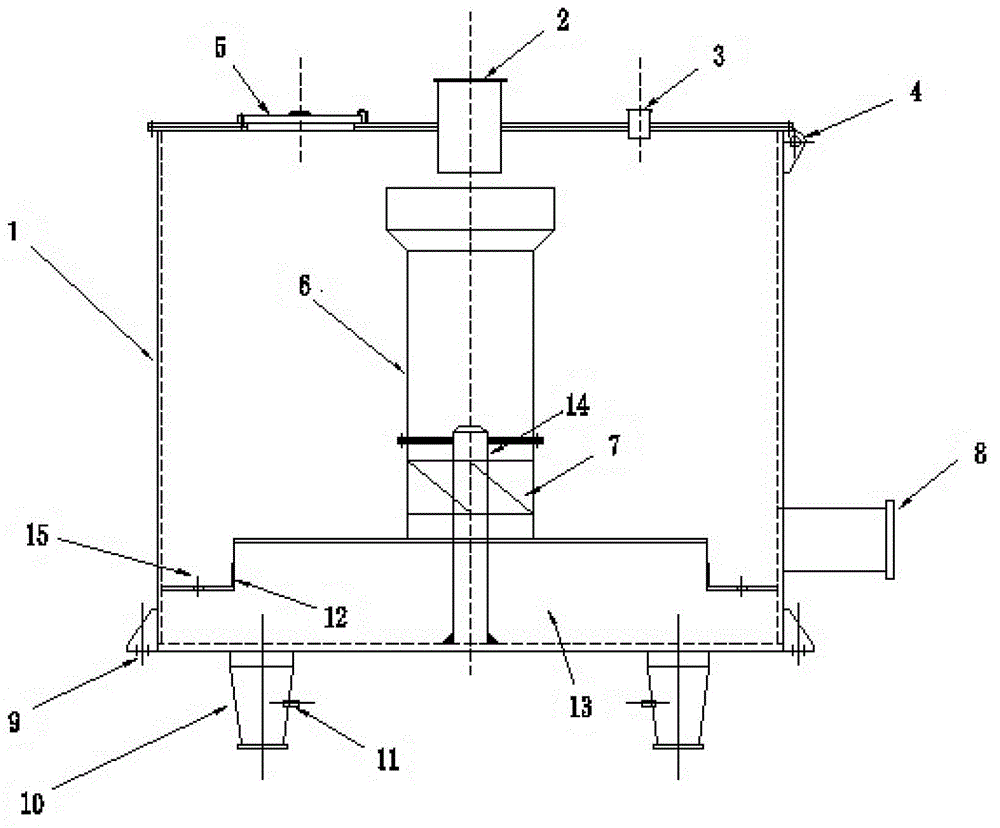

[0023] The outer barrel body 1 and the inner barrel body 6 installed inside the outer barrel body 1 through the rotating shaft 14, wherein:

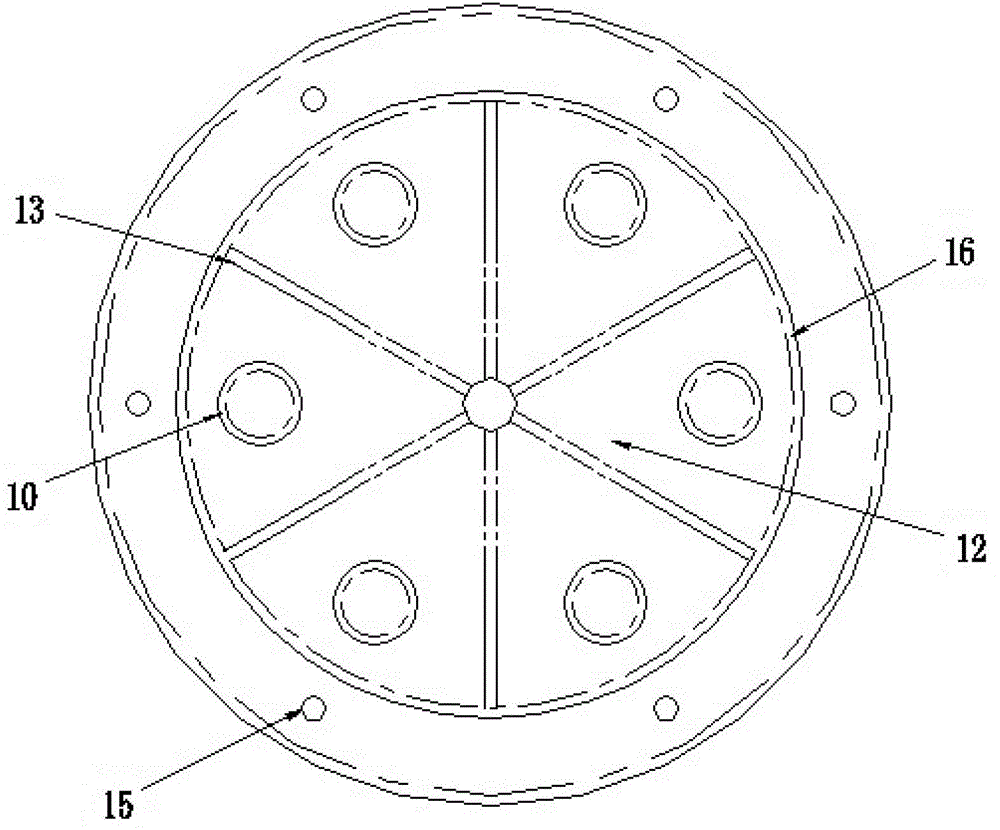

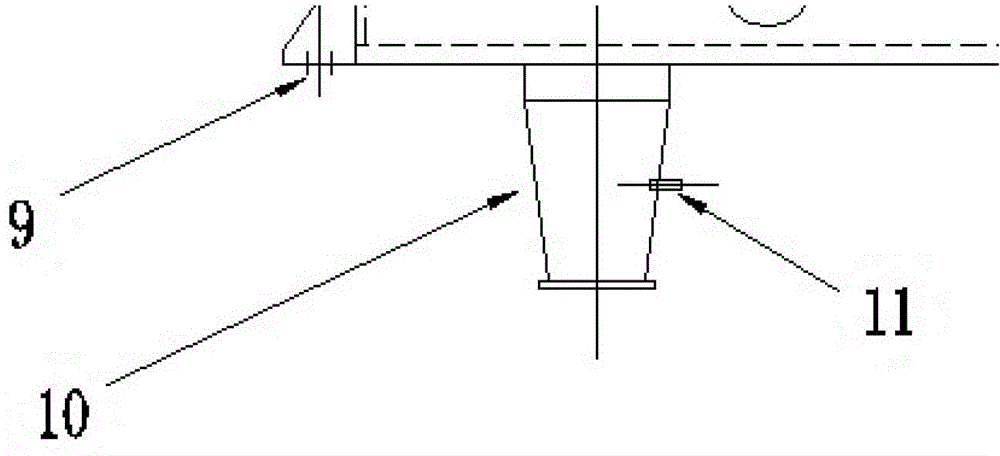

[0024] - The lid of the outer barrel body 1 is respectively provided with an ore inlet 2, a ventilation port 3 and a manhole 5, and several partition plates 13 are arranged at the bottom of the outer barrel body 1, and the partition plates 13 are connected with the inner barrel body 6. An overflow secondary distribution tank 12 is provided at the corresponding position; an overflow pipe 8 is provided on the outer surface of the outer barrel bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com