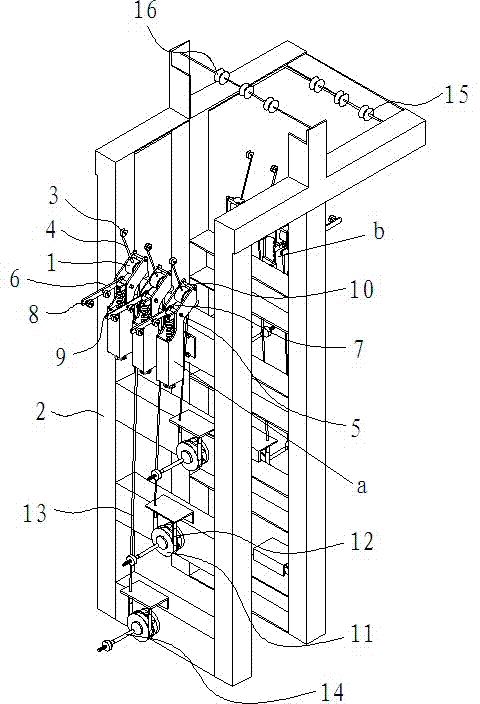

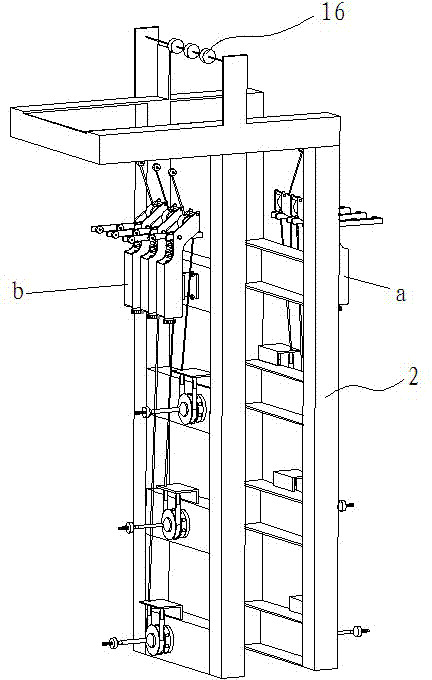

The wiring structure of the wire feeding winch

A wiring structure and wire feeding technology, which is applied in the wiring structure field of the wire feeding winch, can solve the problems of periodic tension changes, large space occupation, and high cost, and achieve the effects of stable wire feeding tension, high wire feeding efficiency, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The wiring structure of the wire feeding winch includes several wire feeding mechanisms, each of which is provided with an output wheel 3; several wire feeding mechanisms form a wire feeding unit, and two groups of the wire feeding units are arranged oppositely to form a feeding wheel. Line unit group, two groups of wire feeding units are respectively forward wire feeding unit a and rear wire feeding unit b, the upper end of the rear wire feeding unit b group is fixed with a wheel frame, and the wheel frame is provided with parallel to each other and the The two sets of transition wheels perpendicular to the wire feeding direction of the wire feeding mechanism are the first transition wheel 15 and the second transition wheel 16 respectively, and the first transition wheel 15 protrudes from the wire feeding end of the back wire feeding unit b On the outside, the second transition wheel 16 protrudes above the wire feeding end of the rear wire feeding unit b.

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com