Cloth roll lifting device of heat shrinkable film cloth roll packaging machine

A packaging machine and heat-shrinkable film technology, applied in packaging and other directions, can solve the problems of prone to skew, heavy cloth rolls, and unfavorable transportation, and achieve the effect of avoiding skew.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

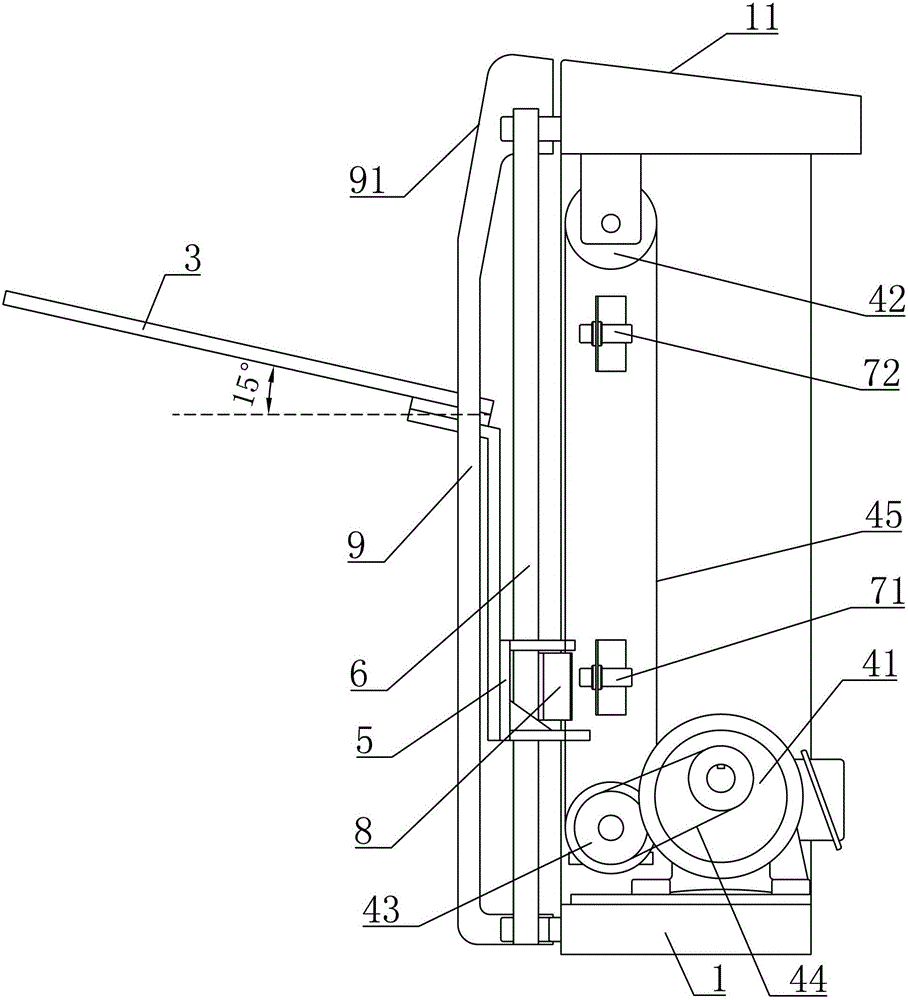

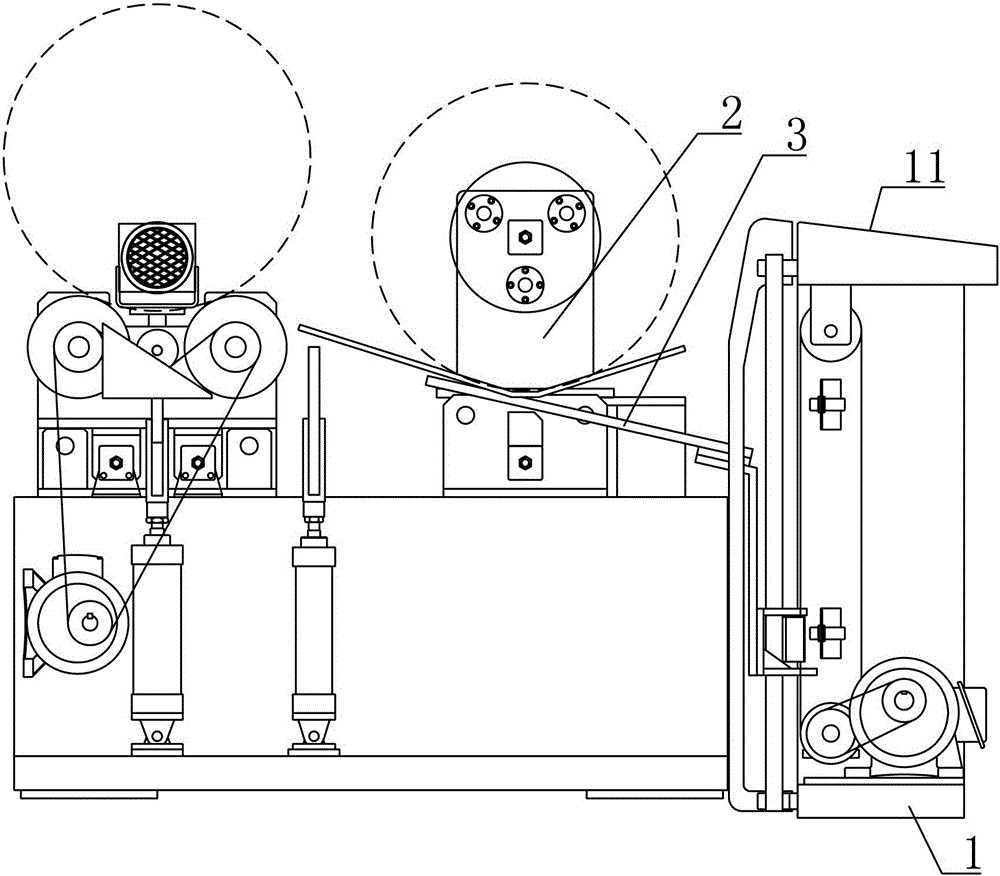

[0014] Embodiment 1: As shown in the figure, a cloth roll lift-off device of a heat-shrinkable film cloth roll packaging machine includes a frame 1 arranged on the rear side of the end flattening device 2, and the frame 1 is provided with a The cloth lifting rod 3 that is suitable for the flattening device 2 and the driving assembly for driving the cloth lifting rod 3 to move up and down, the driving assembly includes a driving motor 41, an upper transmission gear 42 and a lower transmission gear 43 arranged on the frame, and the driving The motor 41 is connected with the lower transmission gear 43 through the first transmission chain 44, and the upper transmission gear 42 is connected with the lower transmission gear 43 through the second transmission chain 45. The rod 3 is fixedly connected with the mobile mounting frame 5, and the cloth lifting rod 3 is inclined upward at 15° from the horizontal plane. A guide column 6 is fixedly arranged in the vertical direction, and the ...

Embodiment 2

[0015] Embodiment 2: Other structures are the same as Embodiment 1, the difference is that: the cloth lifting rod is inclined upward at 1° from the horizontal plane.

Embodiment 3

[0016] Embodiment 3: Other structures are the same as Embodiment 1, the difference is that: the cloth lifting rod is inclined upward at 45° to the horizontal plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com