Ship mooring hole plate

A technology for mooring eye boards and ships, which is applied to ships and other directions, can solve the problems of low cable usage rate, waste of man-hours, and high cost, and achieve the effects of improving installation efficiency, convenient use, and increasing usage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

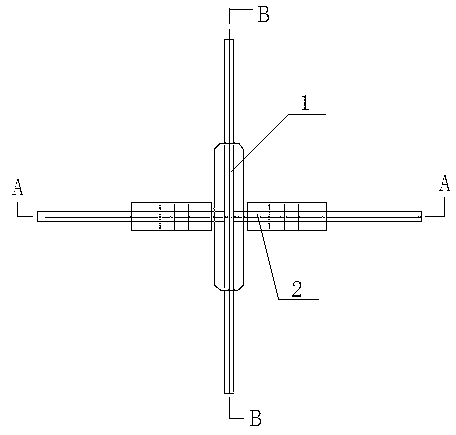

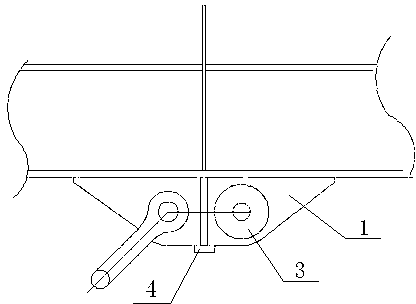

[0012] Such as figure 1 , figure 2 with image 3 As shown, the mooring eye plate of a ship includes a longitudinal web 1, a transverse web 2, a cladding plate 3 and a transverse panel 4, the longitudinal web 1 and the transverse web 2 are cross-welded together, and the cladding plate 3 is installed on On the longitudinal web 1, the transverse panel 4 is installed on the transverse web 2, the longitudinal web 1 is provided with a through hole, and the cladding plate 3 is provided with a hole corresponding to the through hole on the longitudinal web 1, the ship of the present invention The mooring eye plate is prefabricated by using the high-strength AH36 steel plate stocked by the shipyard, and the safe working load mark (SWL85T) is welded, the groove is made, the completion inspection is completed, and the number is put into storage. And note that the welding form between the eye plate and the ship's outer plate is full penetration, and flaw detection is required after weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com