Combined type support structure and assembly method thereof

A bracket structure and combined technology, which is applied in the direction of transportation and packaging, circuit or fluid pipeline, vehicle parts, etc., can solve the problem of cost, increase in mass, encroachment on the layout space of the front cabin, and the large volume of the battery and suspension cushion installation device and other issues, to achieve the effect of simple manufacturing process, cost reduction, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

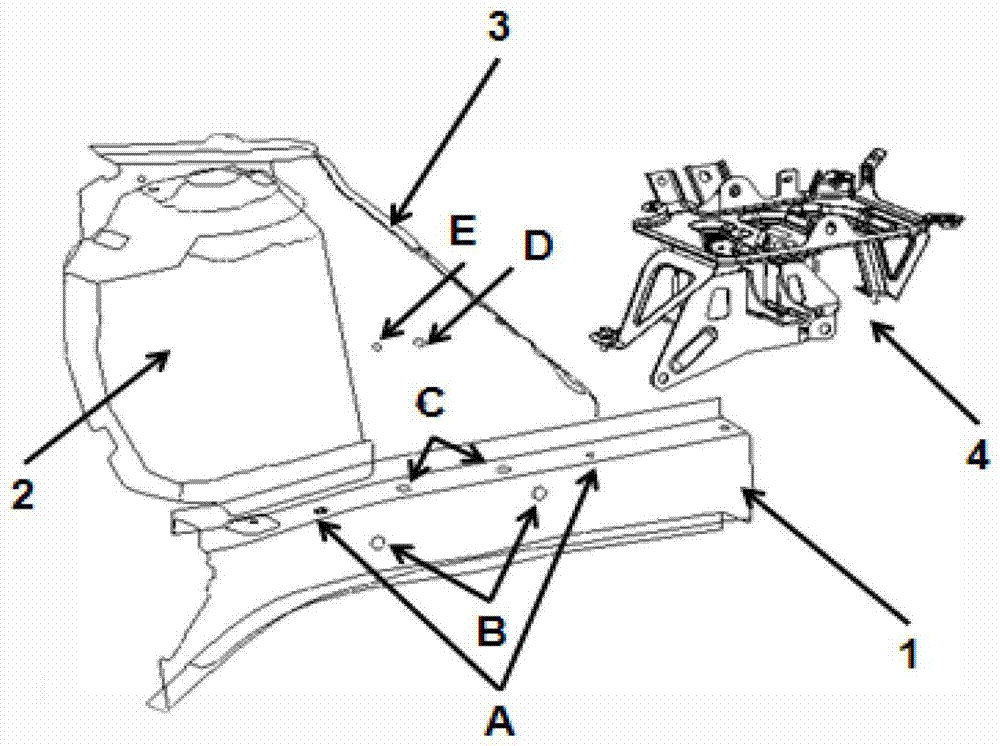

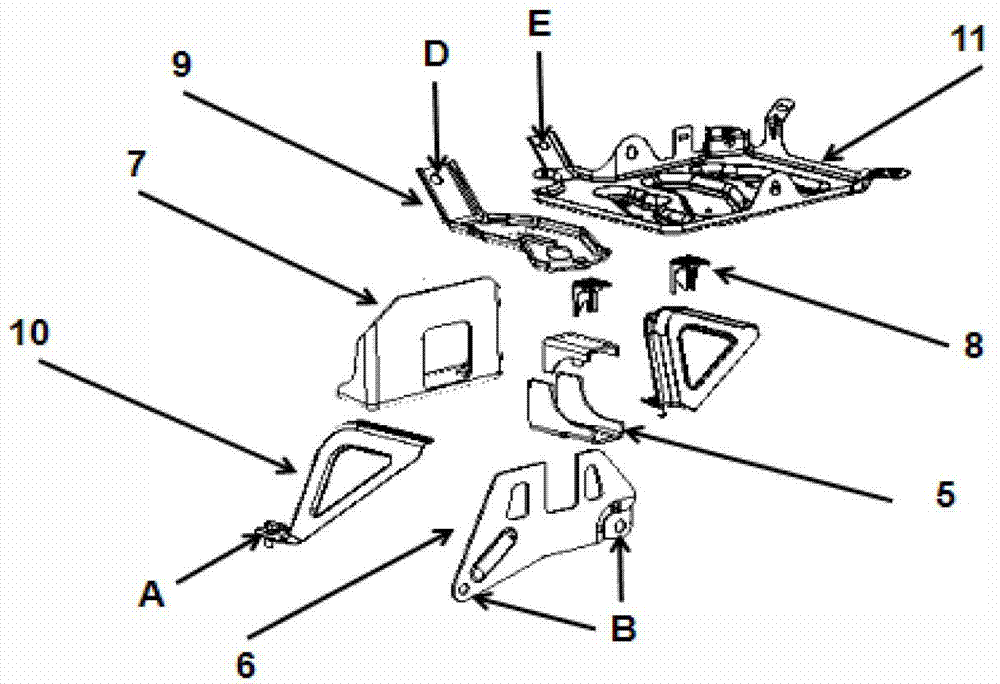

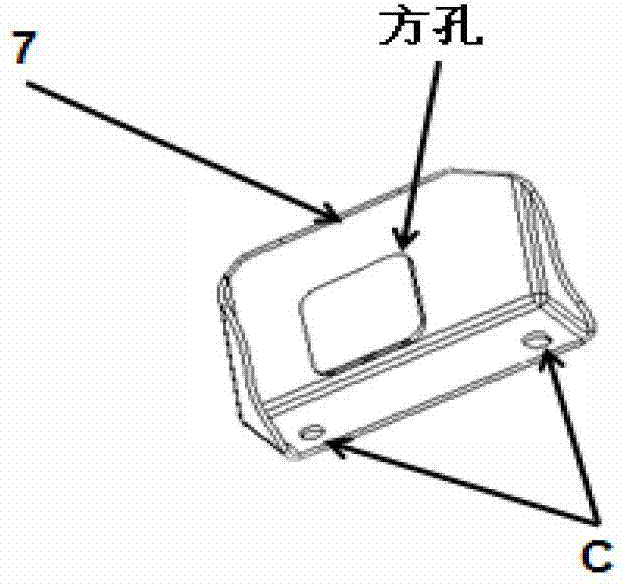

[0070] figure 1 The middle combined mounting bracket 4 is connected with the front longitudinal beam body 1 of the vehicle body through three bolts A, B, and C (six bolts are required). Connect with the body sheet metal part 3 through two bolts at D and E (two bolts are required). The specific structure of the combined mounting bracket is as follows: figure 2 . figure 2 The middle combined support part 5 is composed of upper and lower parts, the upper and lower parts synthesize the pliers mouth-like structure through "radian", and the outsourcing sheet metal parts 12 with rubber suspension cushions (see the attachment for details) Figure 4 ) are seam welded to hold the rubber suspension cushions in place. The combined bracket part 6 is connected with the lower part of the part 5 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com