Automatic assembling machine of air outlet of air conditioner

A technology for air outlets and assembly machines, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc. It can solve the problems of loading blades and connecting rods after connection, heavy workload of assembly workers, and increased labor costs, so as to achieve assembly efficiency High efficiency, good assembly efficiency and fast assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

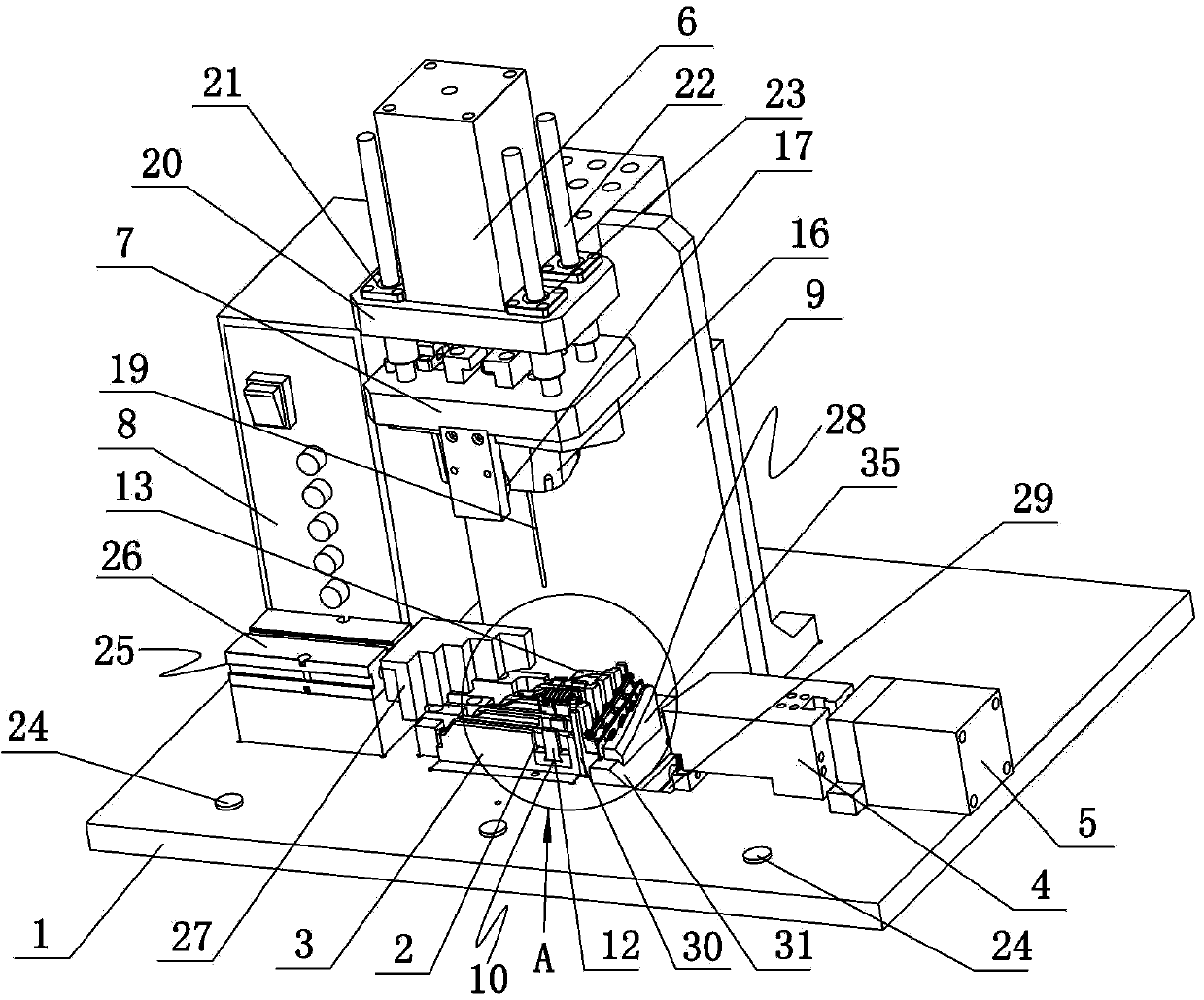

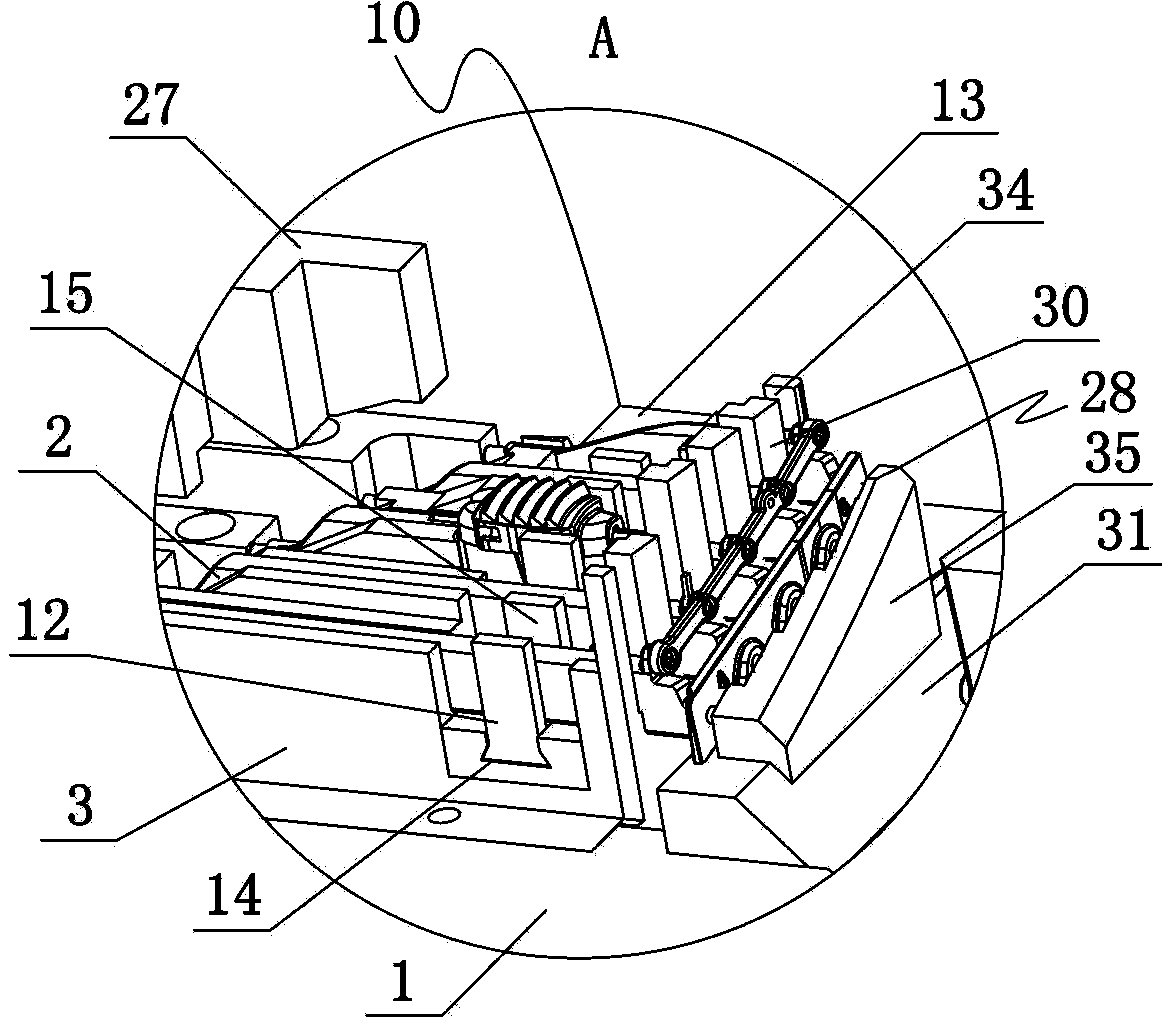

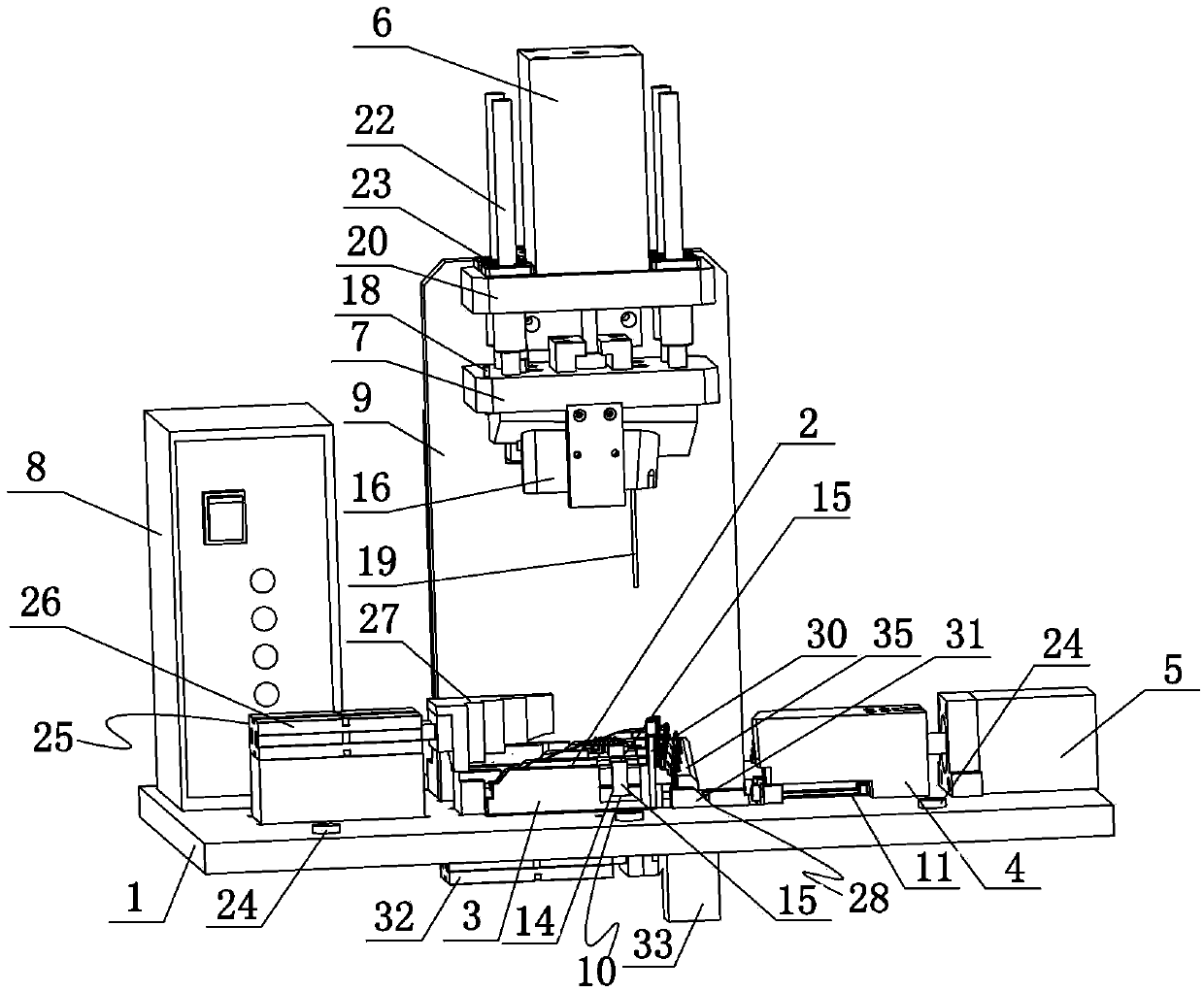

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 An air-conditioning air outlet automatic assembly machine is shown, which includes a bottom plate 1, a positioning block 3 provided with a plurality of blade positioning grooves 2, a connecting rod mounting seat 4 and a connecting rod mounting cylinder 5 (of course other parts are included, but Since the invention point of the present invention is not involved, so it will not be repeated here), the number of blade positioning grooves 2 is set according to the required air-conditioning outlets of different sizes, there are three, four or five, etc., the positioning Block 3 and connecting rod installation cylinder 5 are all fixed on the base plate 1, and described connecting rod mounting seat 4 is slidably connected on the base plate 1 between positioning block 3 and connecting rod ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com