Broach assembly for lathe

A technology of knife components and lathes, which is applied in the direction of broaching machines, broaching machine devices, metal processing machinery parts, etc., can solve the problems of no machine tools, equipment investment and site investment waste, high-priced subcontracting processing, etc., to ensure stability and guarantee The effect of concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below. All other implementations obtained below fall within the protection scope of the present invention.

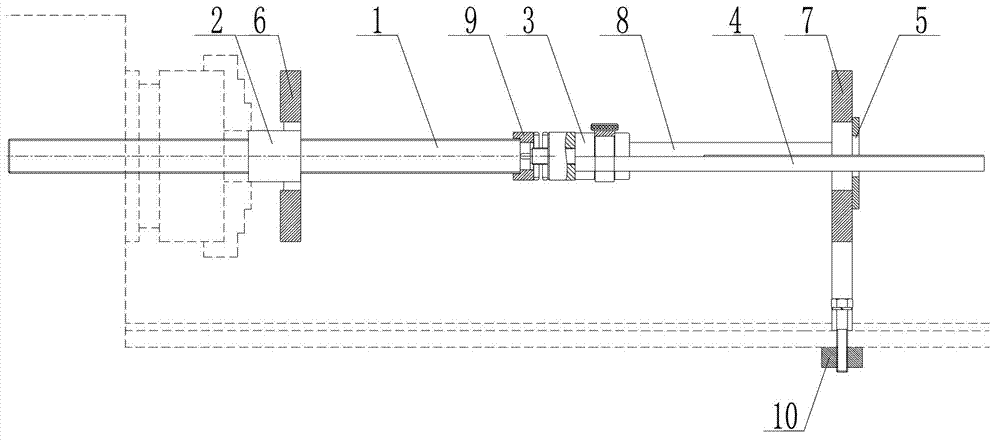

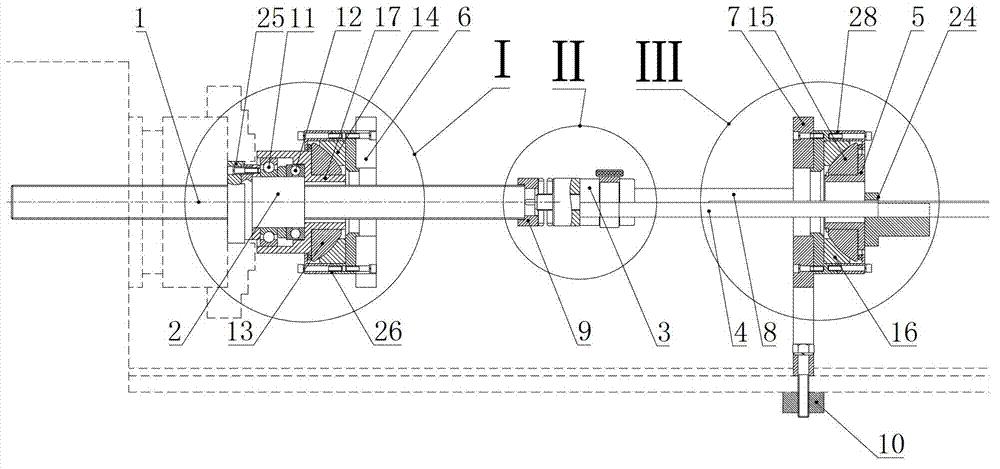

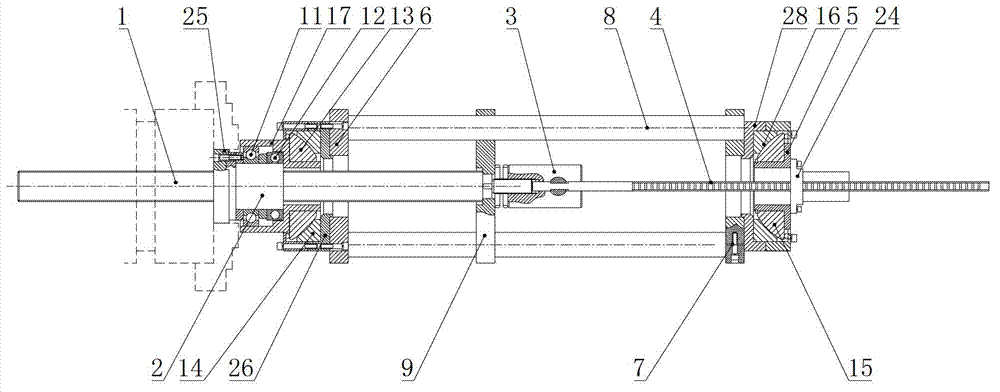

[0044] One embodiment of the present invention provides a broach assembly for a lathe, such as figure 1 As shown, it includes a screw rod 1, a screw nut 2, a guide device, a connecting member 3, a broach 4 and a workpiece fixing device 5;

[0045]The screw 1 and the screw nut 2 are socketed and matched; one end of the screw 1 is connected to the broach 4 through the connecting member 3; the length direction of the broach 4 is the same as the axial direction of the screw 1;

[0046] The guide device includes a front base 6, a rear base 7, a track 8, a guide arm 9 and a fixed member 10 for fixed connection with the lathe;

[0047] The front base 6 is rotatably connected to the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com