Combined heat-work production comprehensive utilization method for chemical energy produced in production of fumaric acid

A production process, fumaric acid technology, applied in the field of comprehensive utilization of chemical energy resources, can solve problems such as waste of energy resources, and achieve the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the present invention, specifically illustrate in conjunction with the following specific embodiments:

[0030] 1. Technical solution

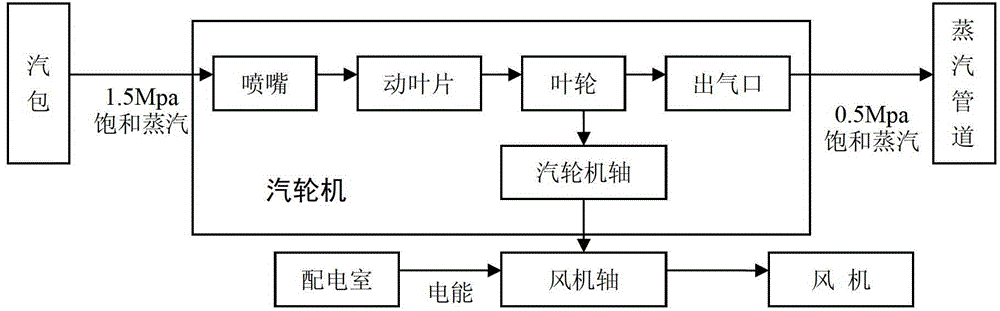

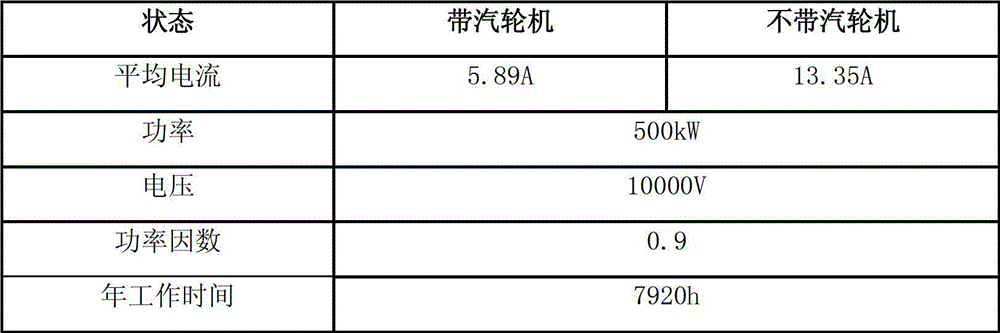

[0031] Install a saturated steam turbine coaxial with the fan after the steam drum of the 5,000-ton benzene oxidation fumaric acid production line. The 1.5Mpa saturated steam in the steam drum is transported to the steam turbine through pipelines, and the saturated steam expands in the steam turbine body to do work, and assists in driving the 500kw fan (it is still driven by electricity when the fan operation requirements are not met), so as to save electric energy. Such as figure 1 shown.

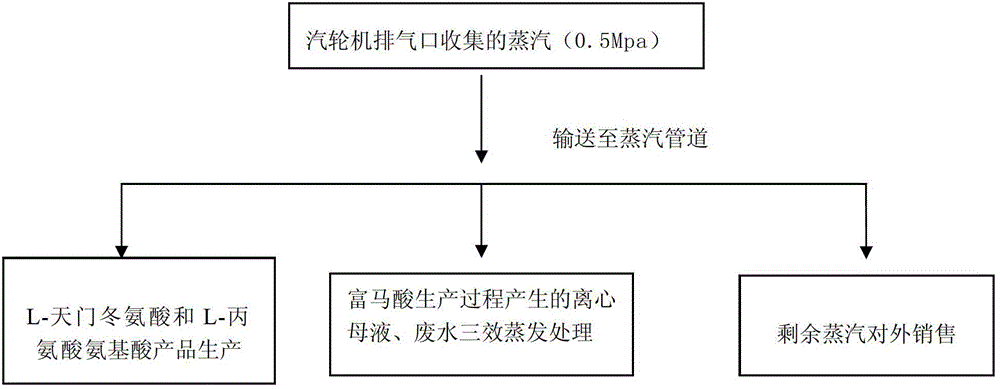

[0032] After the saturated steam of 1.5Mpa is worked by the steam turbine, the saturated steam whose pressure is reduced to 0.5Mpa is discharged through the exhaust port of the steam turbine, and is transported to the fumaric acid drying and crystallization workshop and L-aspartic acid and L-alanine through pipelines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com