Cultivation of green algae chlorococcum pamirum for production of biofuel

A technology of Pamir Chlorella and a culture medium, which is applied to the cultivation field of Pamir Chlorella for producing biofuel, and can solve the problems such as no commercial biodiesel products yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Collection and purification of the green alga Chlorococcus pamirs

[0101] Cells were collected using phytoplankton nets (5 micron pore size) at Yakin River, Forsyth County, NC. After washing with sterile medium, the harvested cells were plated on agar plates containing growth medium (see figure 2 shown). After one week of illuminating the plate with fluorescent light, the cells from the plate were transferred to a new plate using a microbial transfer loop. After 3 transfers, sterile single clones were obtained. A single clone of Chlorococcus pamiris was identified and selected for further cultivation. The cell shape of the Chlorococcus pamiris cell line is like an ellipsoid, and the cells become spherical in fixed culture.

Embodiment 2

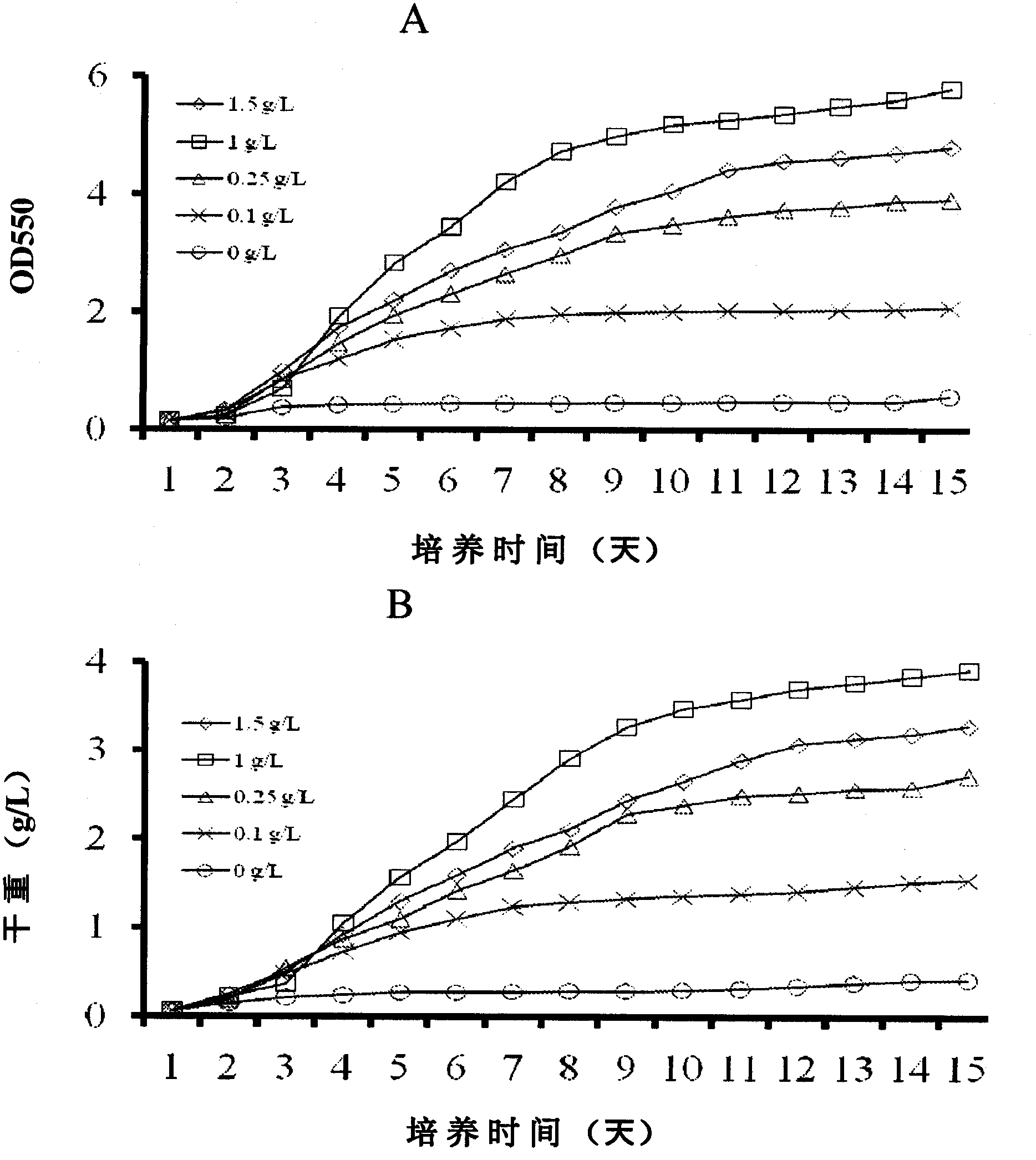

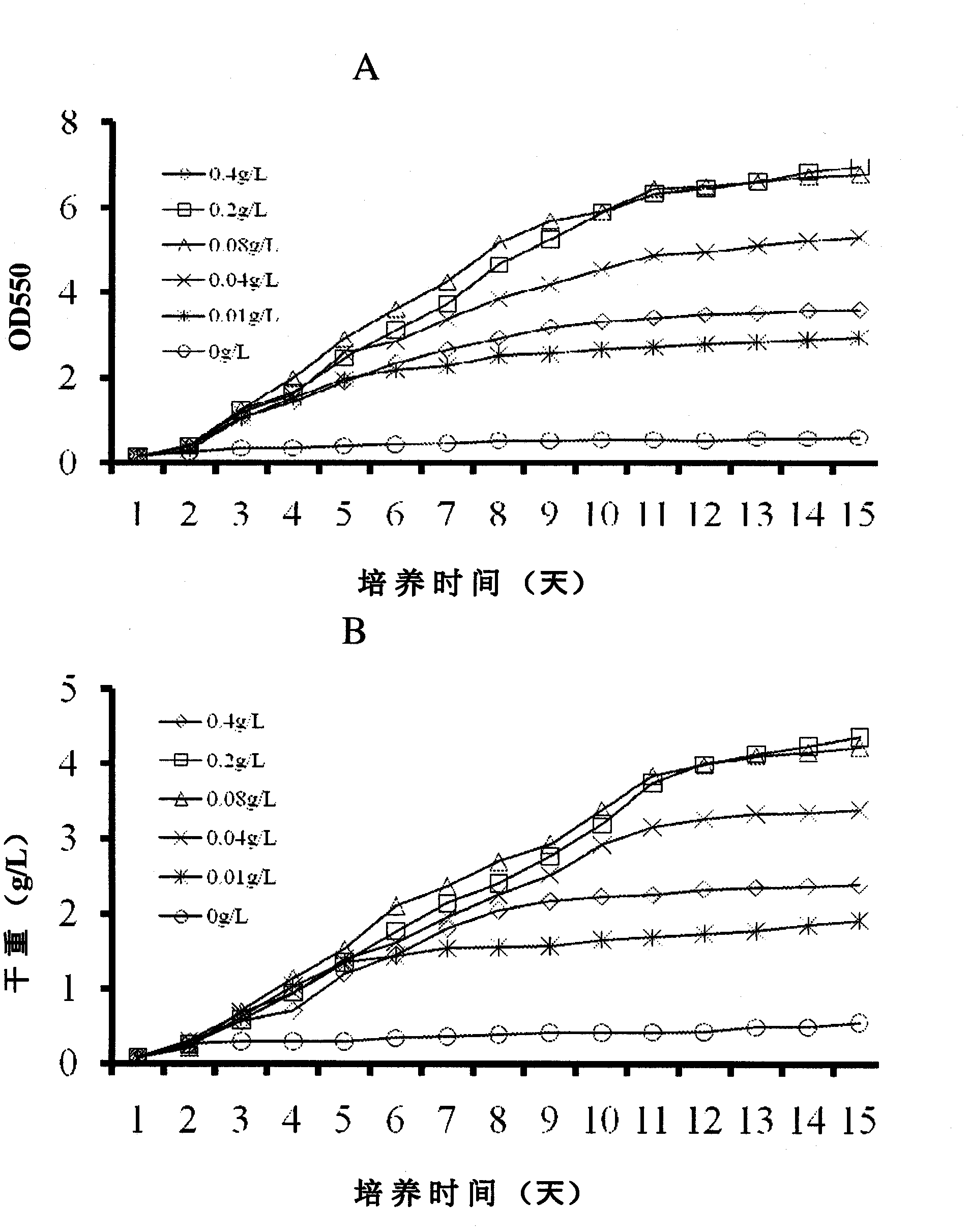

[0103] Cultivation of microalgal cells of the species Chlorococcus pamiris

[0104] General procedure

[0105] Pamirs cells were inoculated into cylinders with internal diameters of 4.5 cm or 2.8 cm, respectively, during exponential growth phase. The maximum culture volumes correspond to cylindrical vessels of 450 ml and 250 ml, respectively. Vessels with an inner diameter of 4.5 cm were used in this experiment to induce lipid enrichment, while other types of cylinders were used in experiments with different growth characteristics. The culture in each culture cylinder was applied with a strength of 100 μmol m -2 the s -1 The temperature is 25° C., and the ventilation is 0.6 liters / minute (filtered air, passing through a microporous membrane with a pore size of 0.22 μm).

[0106] Media and Growth Conditions

[0107] The growth medium used in the present invention to realize the accelerated growth of Chlorococcus pamirs organisms and increase the oil content in the orga...

Embodiment 3

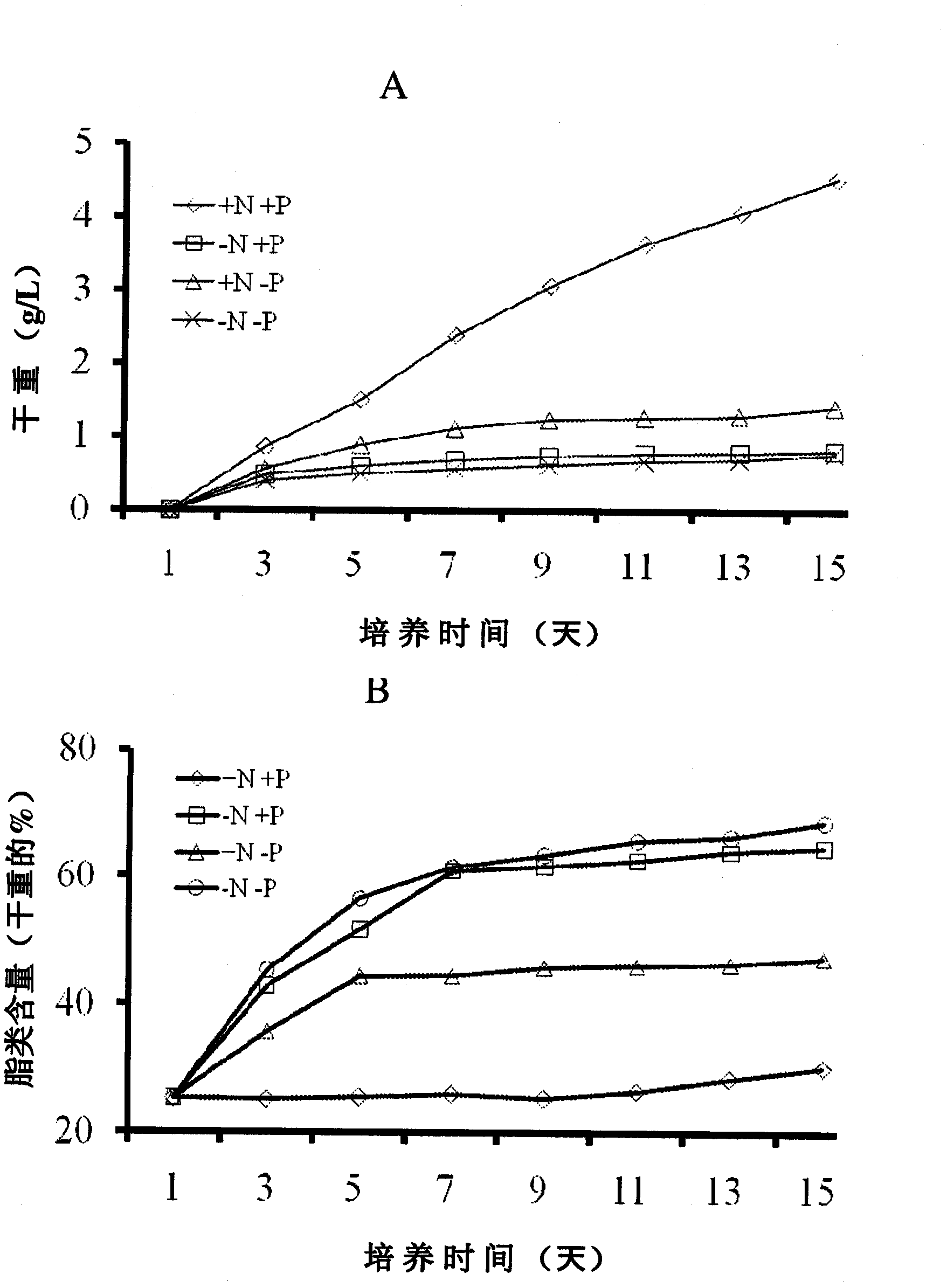

[0115] Increased lipid enrichment of the microalgae Chlorococcus pamiris

[0116] Nitrogen deficiency

[0117] Enhanced lipid enrichment of Chlorococcus pamiriella cells by exposure to nitrogen-deficient media. In this operation, Chlorococcus pamiri cells taken from an 8-liter photobioreactor were washed with a nitrogen-deficient medium containing: 0.025-1.75 g / L magnesium sulfate 7 hydrate, 0.5-3.6 g / L Sodium carbonate, 0.025-0.20 g / L calcium chloride, 0.001-0.005 g / L EDTA disodium, 0.075-1.5 g / L dipotassium hydrogen phosphate 3 hydrate, 0.2-2 mL / L A5 trace elements, The final pH was in the range of 7.4-8.2.

[0118] Then, the cells were cultured in the same nitrogen-depleted medium. After 7-10 days of culturing in the nitrogen-deficient medium, the oil content in the cells of the Chlorococcus pamirs strain was significantly enhanced (the oil content was promoted from the initial 20-30% of the dry weight of the algae to 50-65%) ).

[0119] Phosphorus deficiency condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com