Turbine air cooling blade

A blade, air-cooling technology, applied in the direction of blade support elements, engine elements, machines/engines, etc., can solve problems such as difficult processing, and achieve the effects of improving efficiency, large mechanical load, and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

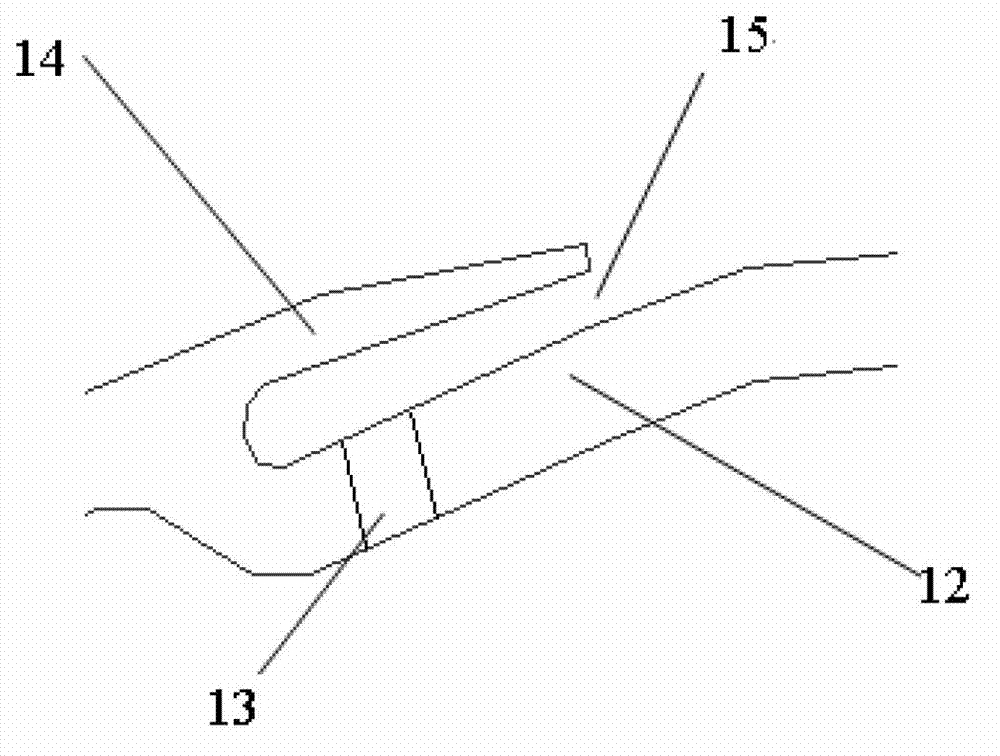

[0015] Below in conjunction with accompanying drawing the present invention is described in further detail, please refer to Figure 1 to Figure 3 .

[0016] Such as figure 1 As shown, a turbine air-cooled blade, the inner cavity is divided into a front cavity 2 and a rear cavity 3 by a partition plate 1, the cooling of the front cavity 2 is supplied by the upper end 4 and the lower end 5, and multiple Exhaust film hole 7, the air film hole 7 has a spatial angle and has components in both axial and radial directions figure 1 The direction and radial direction indicated by 8 in middle figure 1 In the direction indicated by middle 9, cold air sprays and cools the leading edge of the blade through the air film hole 7, and the rear cavity 3 is supplied with air from the upper end 4, and several scale cooling structural units are arranged on the surface of the blade. By setting the scale-shaped cooling structure unit on the surface of the blade, the downstream blade can be covere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com