Waterflooding Development Method for Reservoirs in Ultra-high Water Cut Stage

It is a water flooding technology in ultra-high water cut period, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc. It can solve the problems of development and adjustment difficulties, increase recoverable reserves, and slow down the decline rate of water flooding production. Achieve good development effect and economic benefits, increase recovery rate, and extend the effective period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Taking La 6-PS1733 well as an example, the development method and effect of the present invention are set forth

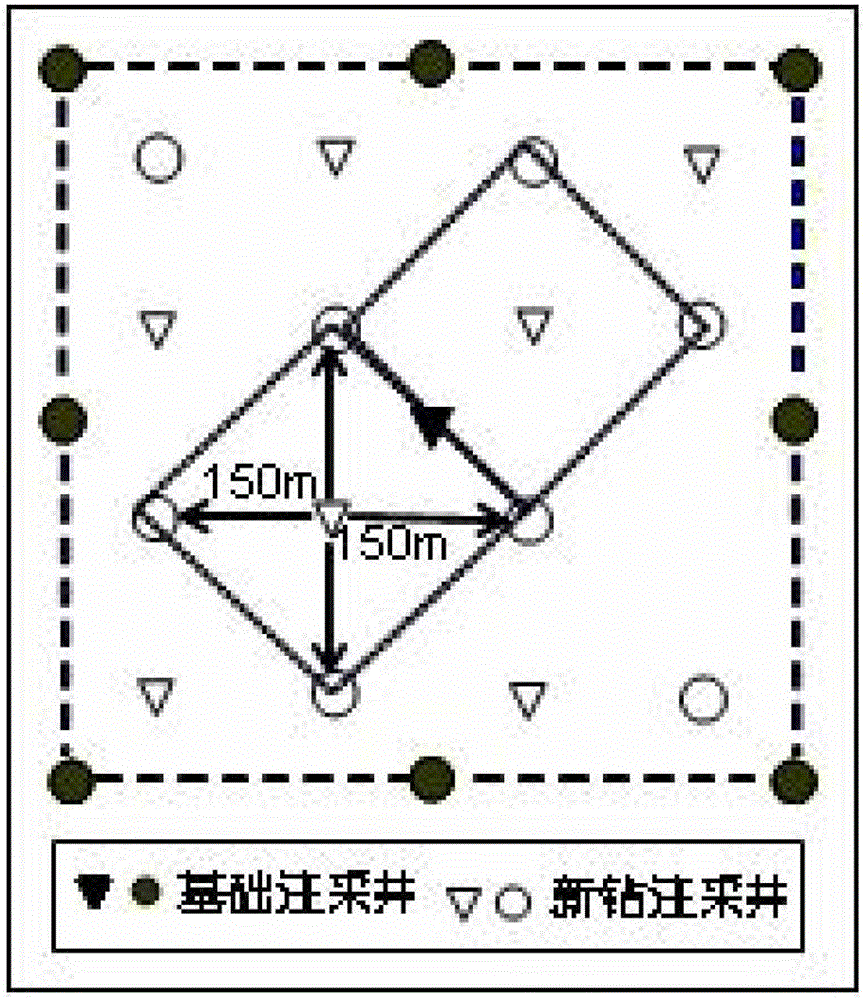

[0024] 1. Use polymer flooding with 150m injection-production well spacing:

[0025] The original water flooding development of the oilfield adopts 300m injection-production well spacing, the average daily liquid production of a single well is 11t, the daily oil production is 0.6t, and the water cut is 94.9%. La 6-PS1733 is used as the production well, and the injection-production well spacing is 150m by polymer flooding.

[0026] 2. Determine the development object:

[0027] Well La 6-PS1733 is a polymer flooding production well in a second-type oil layer in the block, which is used as a water flooding production well, and the target interval is the Sa III4-10 oil layer.

[0028] 3. Further refine oil layer units and analyze the types and functions of structural interfaces:

[0029] Divide the SaⅢ4-10 reservoir into seven structural units, ...

example 2

[0034] Example 2: Taking Well La 7-PS1734 as an example, explain the development methods and effects

[0035] 1. Use polymer flooding with 150m injection-production well spacing:

[0036] The original water flooding development adopts 300m injection-production well spacing, the average daily liquid production of single well is 11t, daily oil production is 0.6t, and water cut is 94.9%. La 7-PS1734 is used as a water injection well, and the injection-production well spacing is 150m by polymer flooding.

[0037] 2. Determine the development object:

[0038] The La 7-PS1734 well group is a polymer flooding injection-production well group in the second type of oil layer in the block, which injects water into the surrounding 4 production wells, namely La 7-PS1731, La 6-PS1723, La 7-PS1801, and La 7-PS1733 Wells, with an injection-production well spacing of 150m, are used as water flooding injection-production well groups, and the target interval is the Sa III 4-10 oil layer.

[0...

Embodiment 3

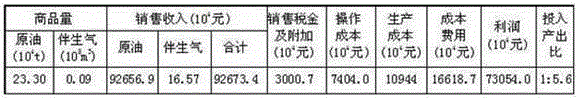

[0045] Embodiment 3: take Lamadian Oilfield as block object, adopt the method of the present invention to develop, and the step of specific development method is:

[0046] 1. Determine the well pattern and use polymer flooding with a 150m injection-production well spacing:

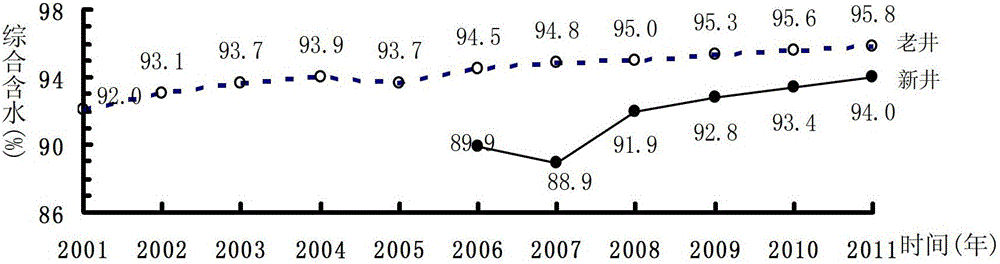

[0047] The practice of oilfield development shows that the control degree of reasonable injection-production well spacing should be higher than 90%, so as to adapt to the geological characteristics of oil reservoirs to the greatest extent and achieve high oil recovery and economic benefits. After the original water flooding 300m injection-production well spacing in block SaⅢ4-10 oil layer was reduced to 150m, the degree of water flooding control was greatly improved, from 86.36% of the original well pattern to 97.64%, an increase of 11.28 percentage points. Among them, three directions The above control degree increased from 72.73% to 86.05%, an increase of 13.32 percentage points, which can achieve a bett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com