A combined structure of a lift pump room and a rear ozone contact pool

A technology for ozone contact pools and structures, applied in drainage structures, buildings, industrial buildings, etc., can solve the problems of pipelines and equipment being easily corroded by ozone, high operation and maintenance costs, and unfavorable safe operation of water plants, etc. The effect of opening times, reducing mutual interference, and facilitating production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

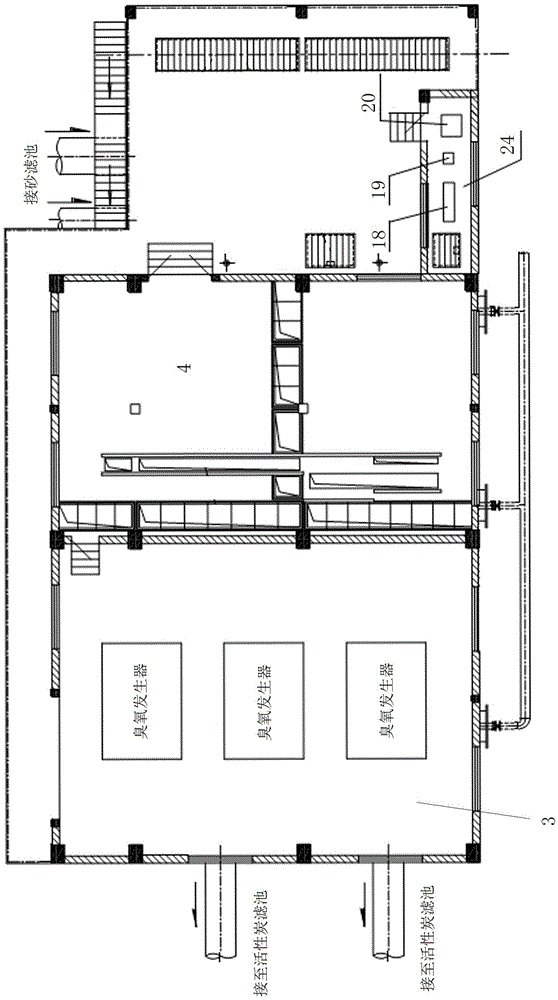

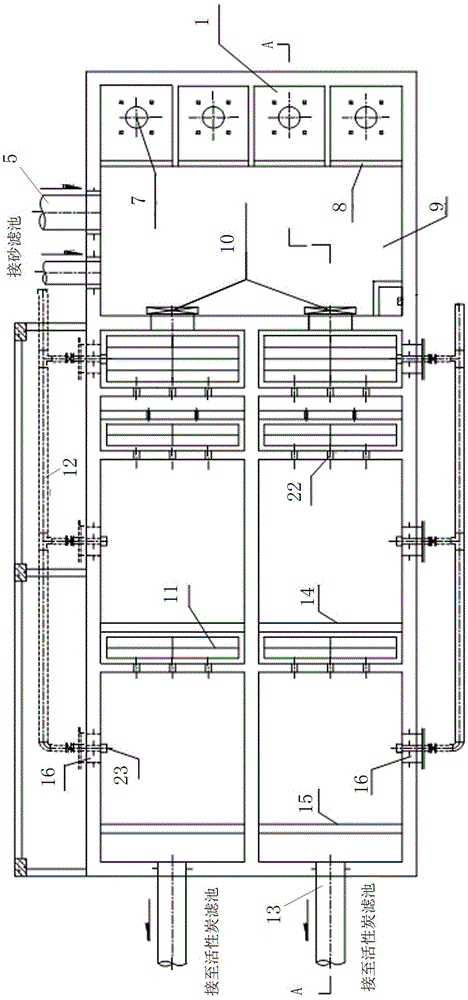

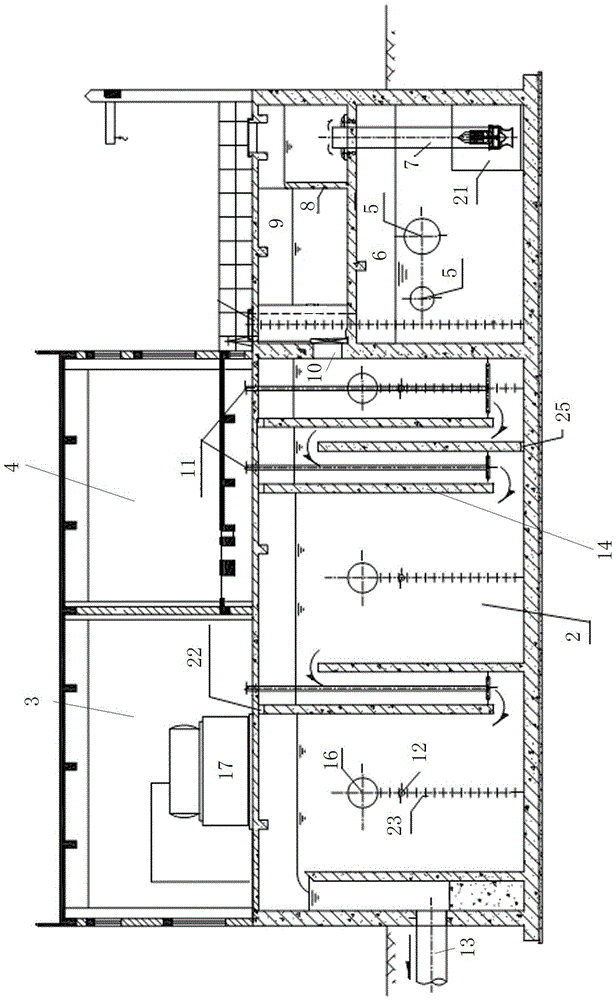

[0009] The present invention will be further described below in conjunction with drawings and implementation.

[0010] The present invention relates to a lifting pump room and a rear ozone contact pool, which mainly includes a lifting pump room 1, a rear ozone contact pool 2, and an ozone generator room 3 and a power distribution room 4 jointly built with it. The lifting pump Room 1 includes upper and lower floors, the lower layer is provided with water inlet pipe 5 and water suction well 6, the upper layer is provided with water outlet confluence channel 9, and a lifting pump and well shaft are arranged between the upper and lower layers to lift the water from the lower layer to the upper layer. In this embodiment , four lift pumps and shafts are provided, and four lift wells are set on the upper layer, overflow weirs 8 are set between each lift well and the outlet confluence channel, each lift well is provided with a lift pump 7, and the lower part of the lift pump is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com