A kind of polyester pleated light-shielding fabric and preparation method thereof

A pleated and polyester technology, applied in the field of polyester pleated shading fabric and its preparation, can solve the problems of affecting the appearance and touch, complex production process, high equipment requirements, and achieve the effect of good pleated style, good shading effect and better pleated structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The utility model will be further described below in conjunction with the drawings.

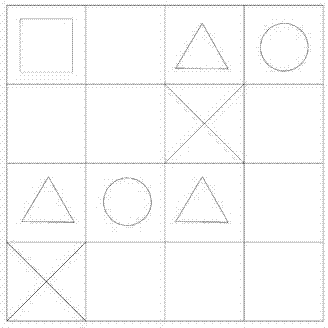

[0016] It is woven with one set of warp yarns and two sets of weft yarns, the warp yarns are made of 100D / 48F cationic polyester low-stretch yarn; the surface wefts are made of 300D / 96F polyester fully drawn yarns, and the inner wefts are made of 300D / 96F polyester fully drawn black yarns; The density is 65 yarns / cm; the weft yarn density is 50 yarns / cm; the total number of warp yarns is 18,360; figure 1 As shown, both the surface layer and the inner layer adopt a plain weave structure, and the weft arrangement ratio of the surface layer and the inner layer is 1:1.

[0017] Put the surface weft into a fully enclosed boiler and heat it from room temperature to 100°C~120°C at a heating rate of 2°C~5°C / min, and keep it at high temperature for 10~20min before taking it out, and wait until the temperature drops to 50°C~80°C Left and right, then refer to figure 1 As shown, according to the conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com