High-adaptability uniform film formation method and device for nanomaterial on substrate

A nano-material and adaptable technology, applied in the field of strong adaptable nano-particle uniform film-forming method and its device, and material preparation field, can solve the problems of complex device, inability to print nano-materials, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

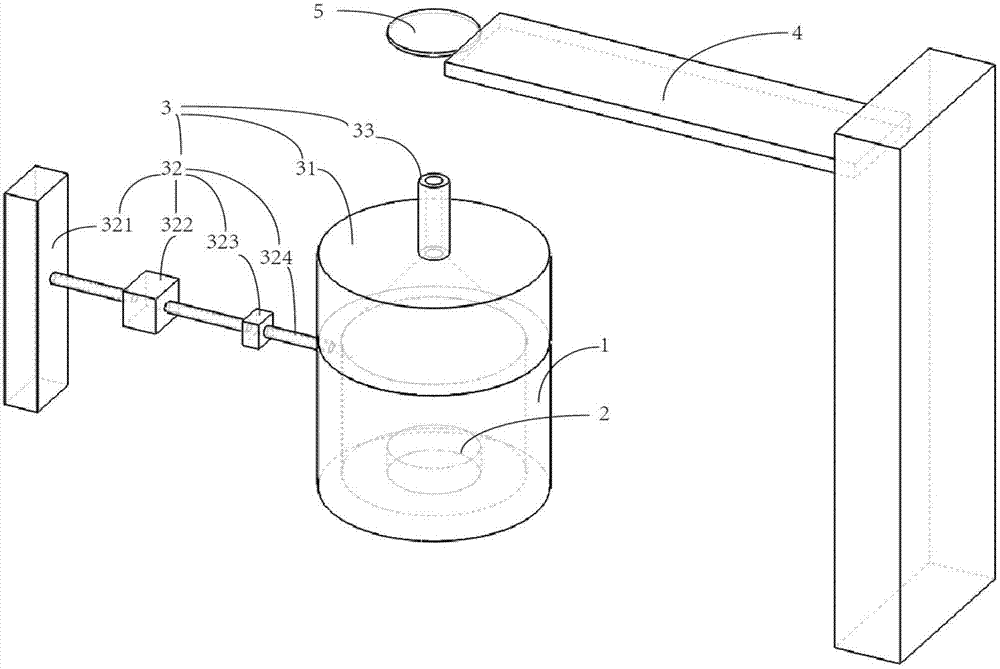

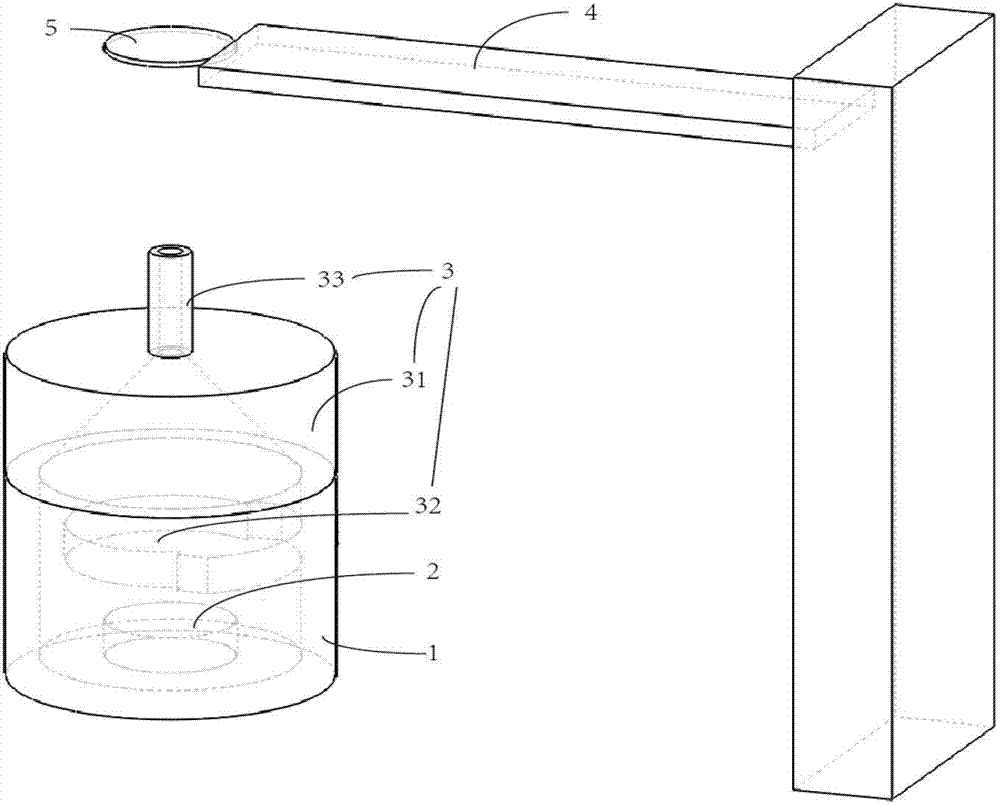

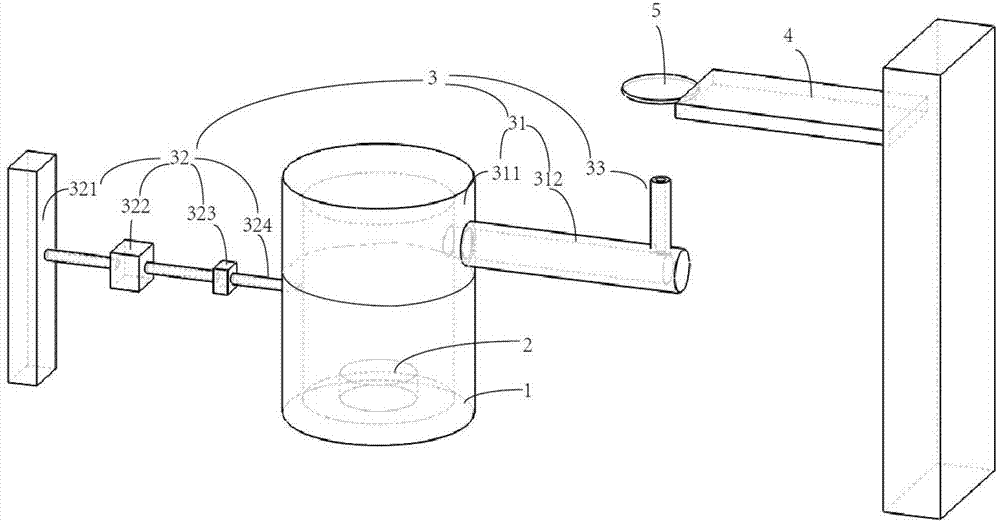

[0053] Substrate strong adaptability nano material uniform film formation device:

[0054] Such as figure 1 As shown, a uniform film-forming device of strongly adaptable nanomaterials on substrates includes: a liquid sample container 1 , an ultrasonic nebulizer 2 , an upward airflow generator 3 , and a system state controller 4 .

[0055] Wherein, the liquid sample container 1 is a cylinder with a sealed bottom, a first opening on the top, a second opening on the side, and a hollow inside, made of PVC, and used to hold nanomaterial mixed liquid or nanomaterial solution.

[0056] The ultrasonic nebulizer 2 is a conventional commercially available product, its power is 300W, its oscillation frequency is 2.4GHz, and it has 10 nozzles. Below the liquid level of the solution, the ultrasonic atomizer 2 includes an ultrasonic atomization sheet, and the distance between the ultrasonic atomization sheet and the nanomaterial mixed liquid or the liquid surface of the nanomaterial soluti...

Embodiment 2

[0070] Substrate strong adaptability nano material uniform film formation device:

[0071] Such as figure 1 As shown, a uniform film-forming device of strongly adaptable nanomaterials on substrates includes: a liquid sample container 1 , an ultrasonic nebulizer 2 , an upward airflow generator 3 , and a system state controller 4 .

[0072] Wherein, the liquid sample container 1 is a cylinder with a sealed bottom, a first opening at the top, a second opening at the side, and a hollow interior, made of quartz material, and used to hold nanomaterial mixed liquid or nanomaterial solution.

[0073]The ultrasonic nebulizer 2 is a conventional commercially available product, its power is 300W, its oscillation frequency is 2.4GHz, and it has 10 nozzles. Below the liquid level of the solution, the ultrasonic atomizer 2 includes an ultrasonic atomization sheet, and the distance between the ultrasonic atomization sheet and the nanomaterial mixed liquid or the liquid surface of the nanoma...

Embodiment 3

[0087] Substrate strong adaptability nano material uniform film formation device:

[0088] Such as figure 1 As shown, a uniform film-forming device of strongly adaptable nanomaterials on substrates includes: a liquid sample container 1 , an ultrasonic nebulizer 2 , an upward airflow generator 3 , and a system state controller 4 .

[0089] Wherein, the liquid sample container 1 is a cylinder with a sealed bottom, a first opening on the top, a second opening on the side, and a hollow interior made of stainless steel, and is used to hold nanomaterial mixed liquid or nanomaterial solution.

[0090] The ultrasonic nebulizer 2 is a conventional commercially available product, its power is 300W, its oscillation frequency is 2.4GHz, and it has 10 nozzles. Below the liquid level of the solution, the ultrasonic atomizer 2 includes an ultrasonic atomization sheet, and the distance between the ultrasonic atomization sheet and the nanomaterial mixed liquid or the liquid surface of the nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com