Pipe snatching device

A technology of sliding base and sliding panel, applied in the direction of lifting device, etc., can solve the problems of time-consuming and laborious, no underground pipeline in coal mine, etc., and achieve the effect of high degree of mechanization, dexterous movement and convenient position adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

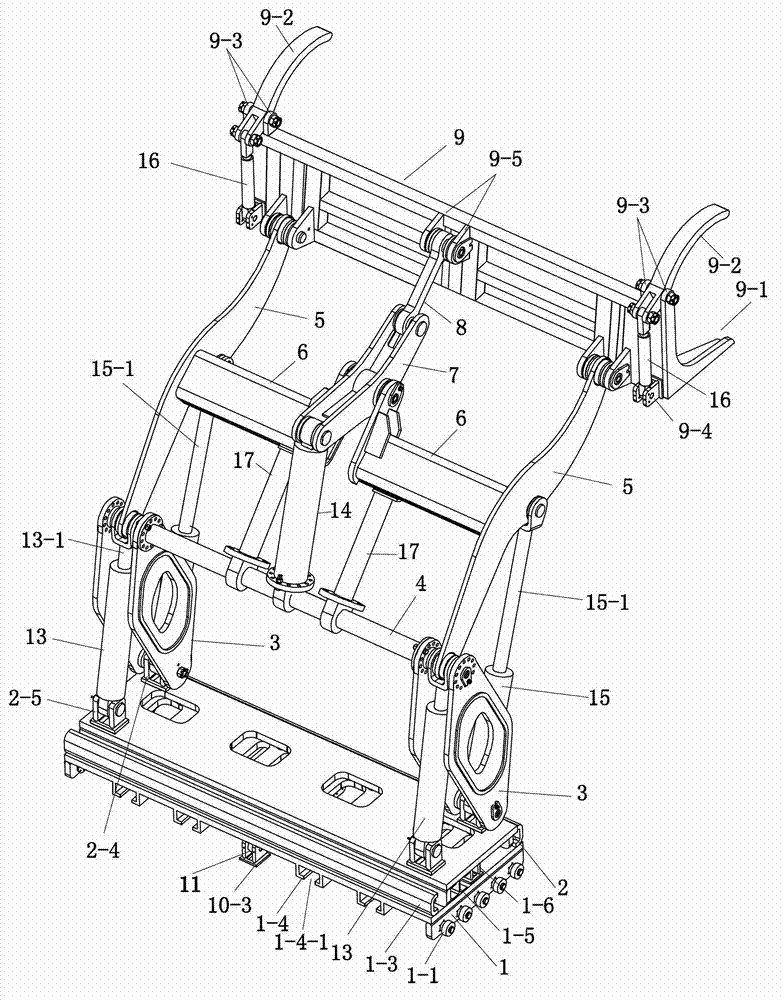

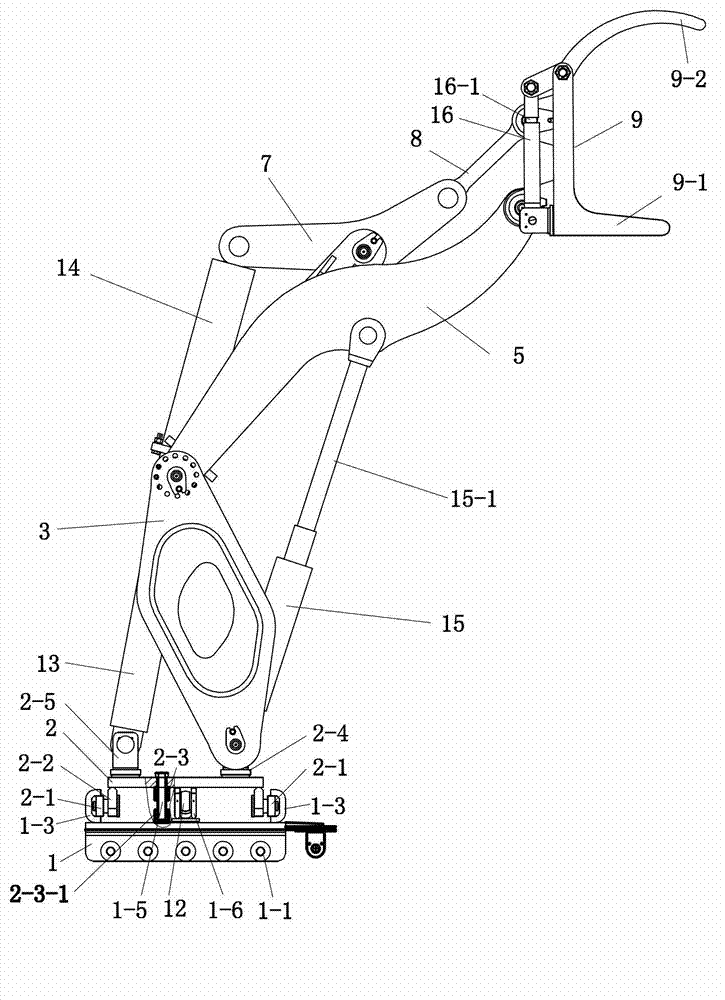

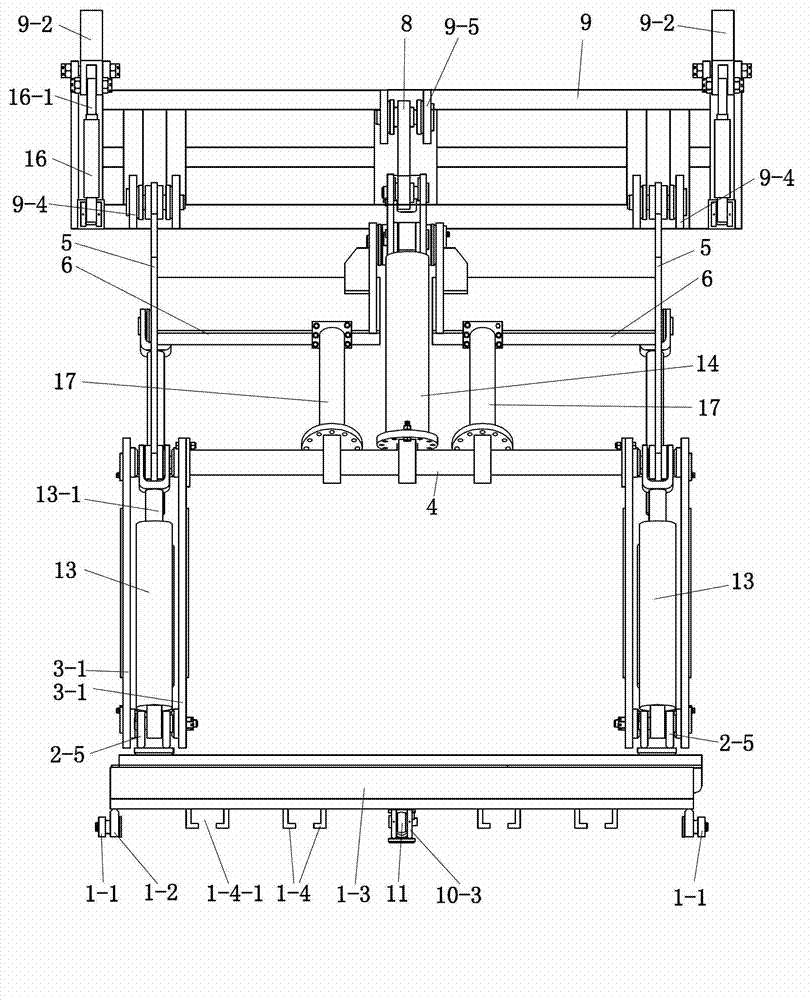

[0020] See Figure 1 to Figure 6 , this embodiment includes a slide table and a main body.

[0021] The sliding table includes a bearing board 10 , a sliding base 1 arranged on the bearing board 10 and a sliding panel 2 arranged on the sliding base 1 .

[0022] The left and right sides of the bearing plate 10 are respectively provided with a slide rail frame 10-1 arranged forward and backward, and at least one T-shaped or I-shaped guide rail 10-2 set forward and backward is fixed on the bearing plate 10 (see Figure 5 and Image 6 ).

[0023] A row of wheel frames 1-2 are respectively fixed on the left and right end faces of the sliding base 1, and each wheel frame 1-2 is connected with a roller 1-1. The two front and rear sides of the slide rail frame 10-1 are on the slide rail surface. Above-mentioned roller 1-1 can adopt rolling bearing. Each guide rail 10-2 corresponding to the carrier plate 10 on the bottom surface of the sliding base 1 is fixed with a pair of angled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com