Multifunctional manipulator device for injection molding machine and quality full-inspection method for injection products

A technology for multi-functional manipulators and injection molding products, applied in the field of injection molding machines, can solve the problems of slow detection mode, inability to ensure the pass rate of ex-factory products, and inability to achieve full inspection of products, so as to ensure quality, improve comprehensive competitiveness, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

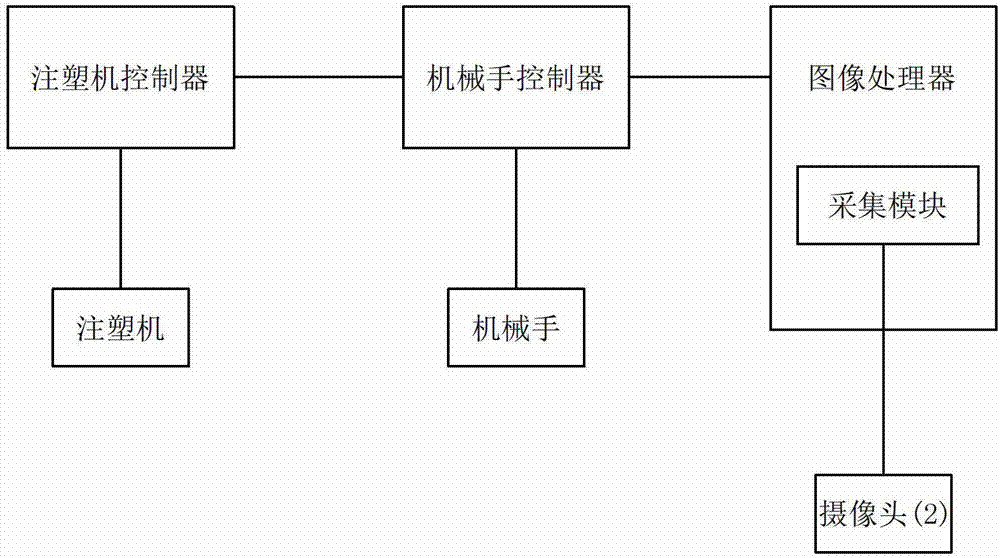

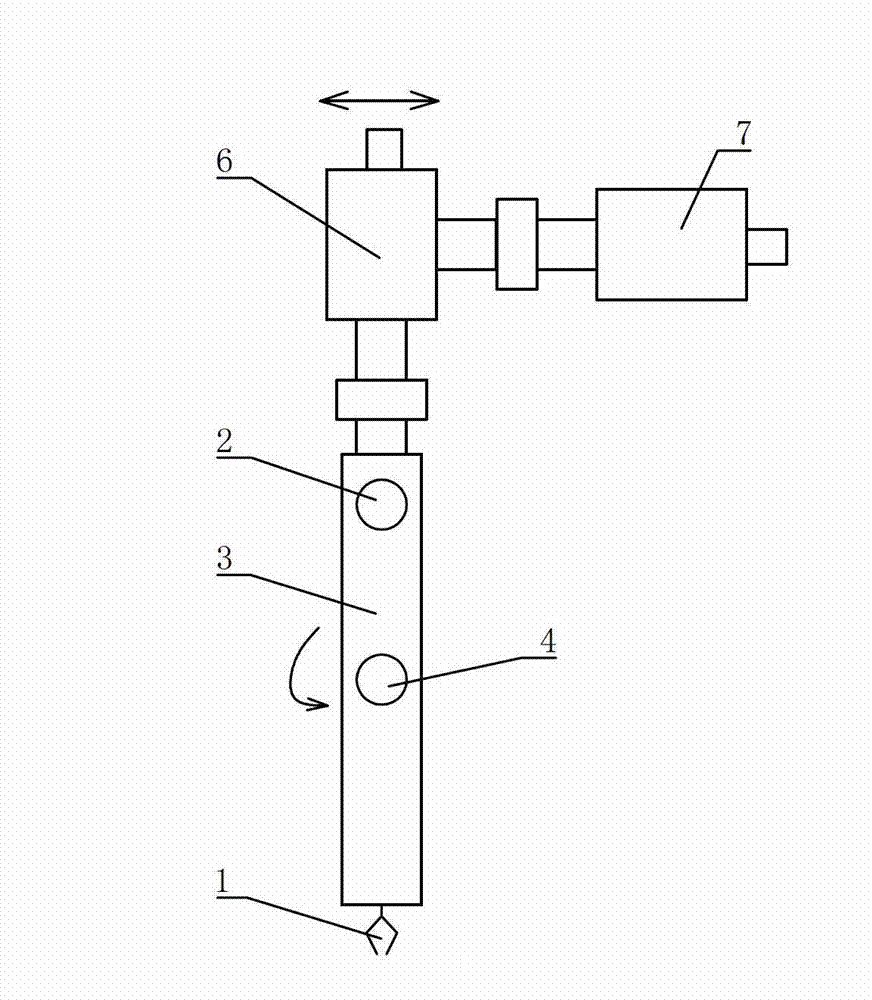

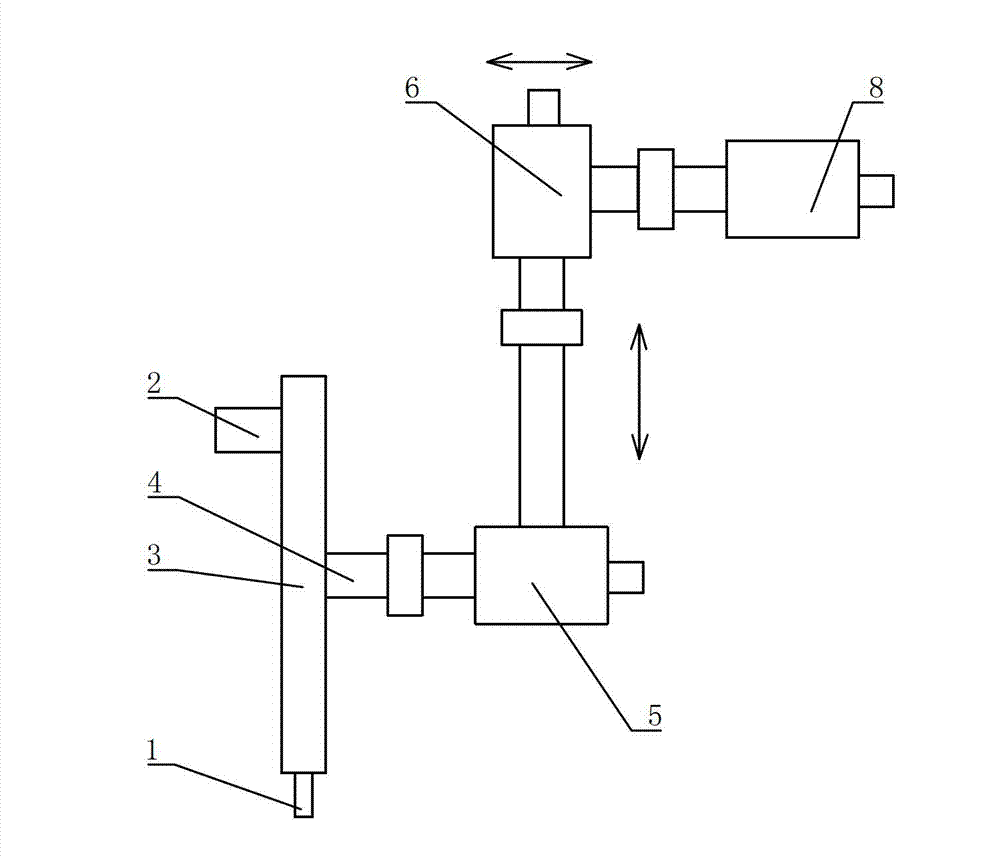

[0023] Such as Figure 1-Figure 3 As shown, a multifunctional manipulator device for an injection molding machine, including a manipulator and a control system.

[0024] A product fixture 1 and a camera 2 are provided on the manipulator, and the manipulator has at least degrees of freedom in x, y, and z directions, that is, the product fixture 1 and camera 2 also have degrees of freedom in these three directions, and can move in space.

[0025] The control system includes a manipulator controller and an image processor. The manipulator is electrically connected to the manipulator controller and the movement of the product fixture 1 and the camera 2 is controlled by the manipulator controller. The image processor is electrically connected to the camera 2 to control the shooting and processing of the camera 2. The captured image samples are electrically connected to the image processor and the manipulator controller, and the two control each other and feed back signals to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com