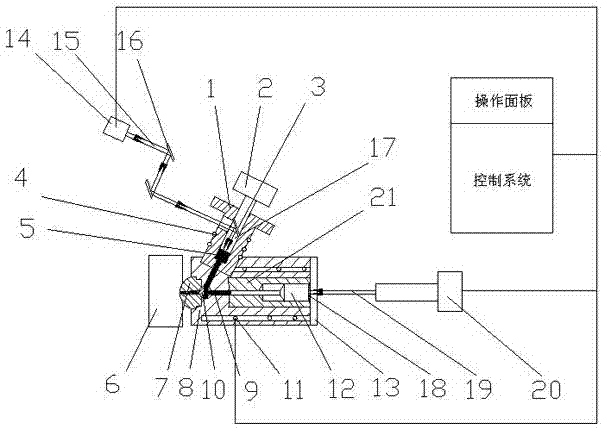

Micro-injection moulding method based on laser plasticizing and impacting technology and apparatus

A technology of laser shock and micro-injection, which is applied in the direction of coating, etc., can solve the problems of poor stability of one-time injection volume control accuracy and molding quality, difficult screw processing, and high strength requirements, and achieve simple structure, high injection molding quality, and melting Uniform plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

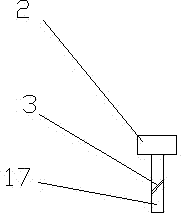

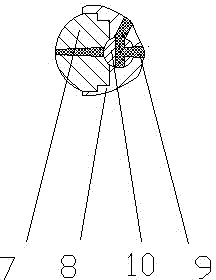

Method used

Image

Examples

example 1

[0042] Example 1, taking typical thermoplastic PMMA as an example, the melting temperature range of plastic PMMA is 250-370 degrees, CO 2 The laser is used as a laser for plasticization, and the laser wavelength generated is 10.6 microns, and the plastic PMMA has a 2 Laser absorption is good. The valve is in the working state 2. After drying, the plastic PMMA particles, with a diameter of 2mm, a height of 2mm, and a mass of 6.5mg, are put into the plasticizing cylinder with a preheating temperature of 105-220 degrees, and the plasticizing rod is pressed against the PMMA particles. , the laser starts to work, and outputs a continuous wave low-power laser with a spot diameter of 5mm and a power of 2W, and is irradiated at a fixed point, and the irradiation time is 0.05-0.1s. After the plastic PMMA is plasticized, the valve turns to working state 1, and the plasticizing rod pushes the plastic melt into the injection unit. After the plastic melt is injected into the injection uni...

example 2

[0043] Example 2, taking typical thermoplastic polyurethane TPU as an example, the melting temperature range of plastic TPU is generally between 170-205 degrees, CO 2 The laser wavelength generated by the laser is 10.6 microns, and the plastic TPU absorbs it well. The diameter of plastic TPU particles is 2mm and the thickness is 2mm. After drying, weigh 50mg with a precision balance and put it into a plasticizing cylinder with a preheating temperature of 140-170 degrees. 2 The laser starts to work, outputting a continuous wave low-power laser with a spot diameter of 3mm and a power of 3W, and continuously scans and irradiates the plastic TPU for 5s. The plastic TPU is plasticized and injected into the injection unit. The pulse wave laser of the laser shock injection system generates high-energy pulse laser. The energy of the pulse laser is 5J, the diameter of the spot is 5mm, and the pulse width is 20ns. The absorbent absorbs the laser energy and is ionized by high temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com