Rolling type wire drawing machine for aluminum plate wiredrawing texture forming

A technology of rolling wire drawing machine and wire drawing machine, which is applied to the parts of grinding machine tools, the control of workpiece feed motion, grinding machines, etc. external problems, to achieve the effect of increasing the utilization rate of water sources, stabilizing product quality, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

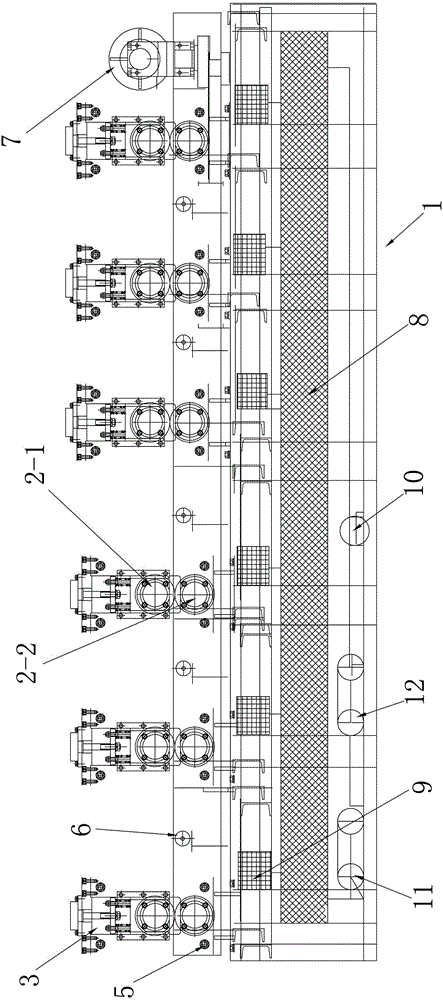

[0015] See attached figure 1 And attached figure 2 As shown, the rolling wire drawing machine for forming the wire drawing texture of the aluminum plate described in this embodiment includes a wire drawing machine host 1, wherein, the wire drawing machine host 1 is horizontally provided with multiple groups of rollers arranged side by side along the wire drawing direction at intervals And the water spray washing system used for product cleaning, each group of rollers is composed of paired upper and lower rollers 2-1, 2-2, the upper roller 2-1 can move up and down, and the lower roller 2-2 Fixed, above the two ends of each upper roller 2-1, there is a turbine motor 3 for driving the upper roller 2-1 up and down to adjust its balance degree, and the turbine motor 3 is fixed on the wire drawing machine host 1 Above, the turbine motor 3 at both ends of each upper roller 2-1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com