Method for cleaning an electrode shield for polysilicon production reduction furnaces

A technology of protective cover and reduction furnace, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., which can solve problems such as non-reuse, equipment damage, and current short circuit, and achieve reduction of industrial solid waste discharge Quantity, fast cleaning speed, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for cleaning an electrode protective cover for a polysilicon material production reduction furnace, comprising the following steps:

[0030] (1) Immerse the silicon dioxide electrode protection cover to be cleaned in sodium hydroxide alkali solution with a mass fraction of 10%, and perform ultrasonic cleaning at 60°C for 120 minutes; the ultrasonic frequency during the ultrasonic cleaning process is 0.2KHz;

[0031] (2) After the ultrasonic cleaning is completed, use 60°C deionized water to spray and wash until the pH of the eluate is neutral. After drying with nitrogen gas at 60°C for 60 minutes, a clean regenerative electrode protective cover A is obtained.

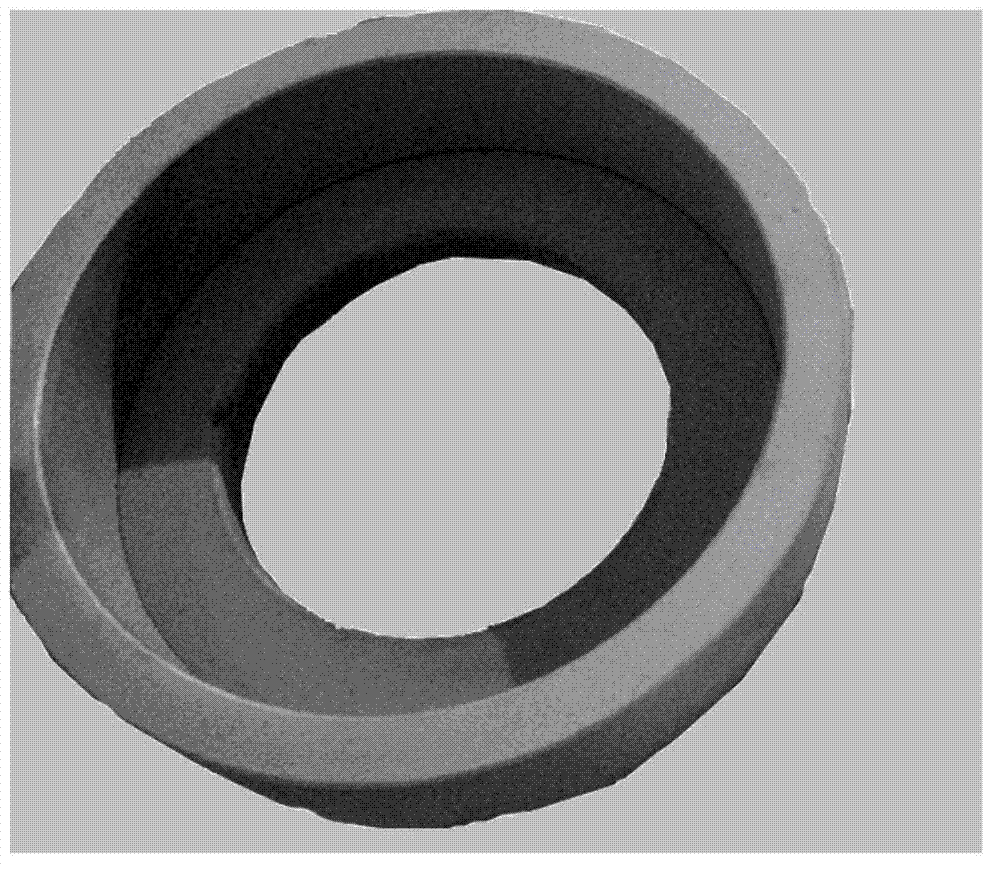

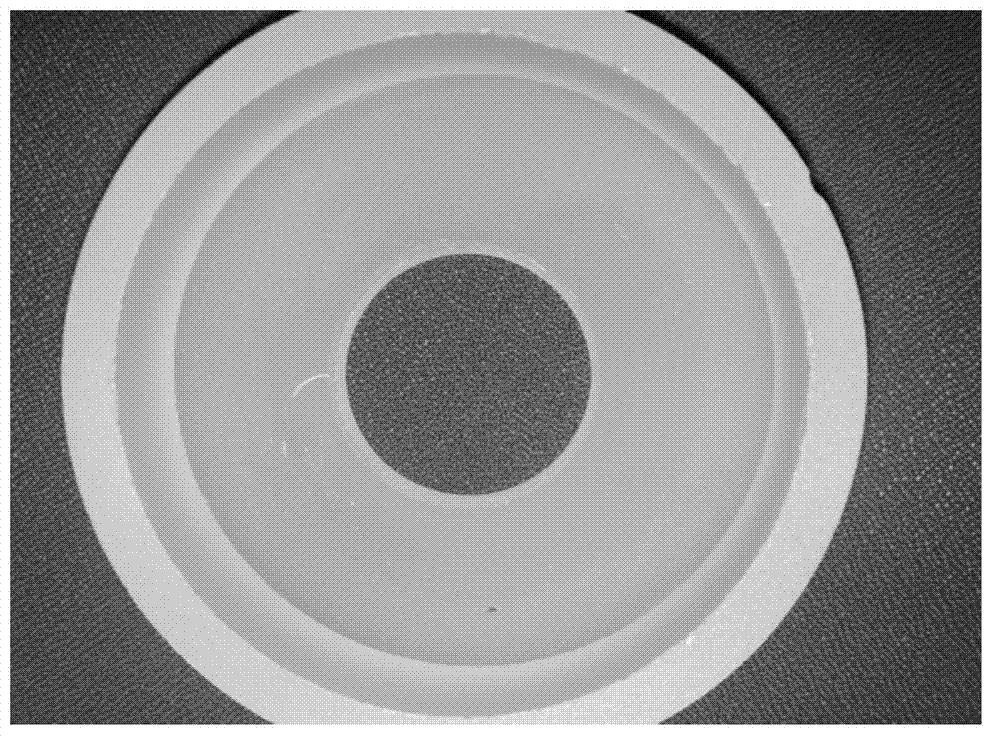

[0032] figure 1 It is the photo of the electrode protective cover before cleaning in this embodiment; figure 2 It is a photo of the regenerated electrode protective cover after cleaning in this embodiment. It can be seen from the figure that the surface of the electrode protective cover after cleaning...

Embodiment 2

[0036] A method for cleaning an electrode protective cover for a polysilicon material production reduction furnace, comprising the following steps:

[0037] (1) Immerse the silicon dioxide electrode protection cover to be cleaned in sodium hydroxide alkali solution with a mass fraction of 8%, and perform ultrasonic cleaning at 40°C for 200 minutes; the ultrasonic frequency during the ultrasonic cleaning process is 5KHz;

[0038] (2) After ultrasonic cleaning, clean the electrode protective cover with deionized water at 40°C for 30 minutes;

[0039] (3) Subsequently, the electrode protective cover was soaked and cleaned with hydrochloric acid at 30°C for 30 minutes;

[0040] (4) Finally, wash with deionized water at 40°C until the pH of the eluate is neutral, and dry with nitrogen at 80°C for 20 minutes to obtain a clean regenerative electrode protective cover B.

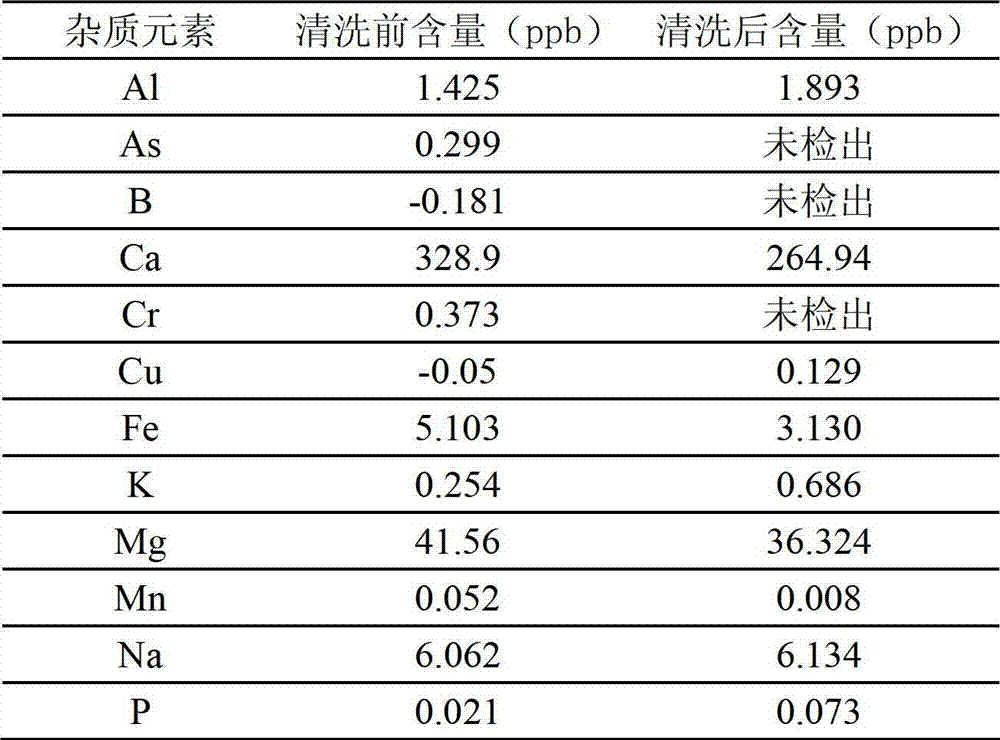

[0041] After testing, the removal rate of silicon on the surface of the electrode protective cover in this embodi...

Embodiment 3

[0043] A method for cleaning an electrode protective cover for a polysilicon material production reduction furnace, comprising the following steps:

[0044] (1) Immerse the silicon dioxide electrode protection cover to be cleaned in potassium hydroxide alkali solution with a mass fraction of 6%, and perform ultrasonic cleaning at 30°C for 60 minutes; the ultrasonic frequency during the ultrasonic cleaning process is 10KHz;

[0045] (2) After ultrasonic cleaning, clean the electrode protective cover with deionized water at 60°C for 2 minutes;

[0046] (3) Then, the electrode protective cover was soaked and cleaned with citric acid at 40°C for 20 minutes;

[0047] (4) Finally, wash with deionized water at 20°C by bubbling and spraying until the pH of the eluate is neutral, and dry with nitrogen gas at 50°C for 50 minutes to obtain a clean regenerative electrode protective cover C.

[0048] After testing, the removal rate of silicon on the surface of the electrode protective cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com