A hammer crusher

A crusher, hammer impact technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problem of horizontal expansion of few new categories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

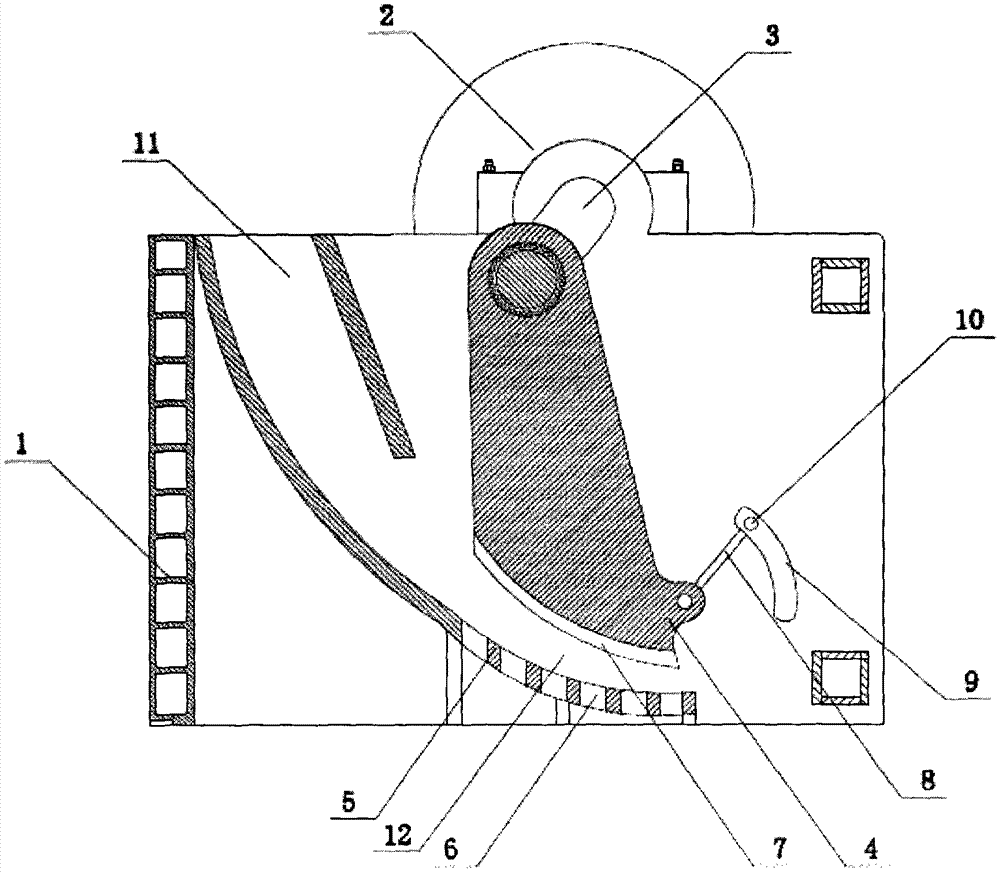

[0033] Example: such as figure 1 As shown, a hammer crusher includes a frame 1 , a crank drive shaft 3 and a transmission wheel 2 , and the crank drive shaft 3 is arranged on the frame 1 and connected with the transmission wheel 2 .

[0034] A heavy hammer 4 is arranged on the crank drive shaft 3, and a movable hammer plate 7 and a fixed hammer plate 5 are arranged obliquely under the heavy hammer 4. The movable hammer plate 7 is assembled on the lower end of the heavy hammer 4, and the fixed hammer plate 5 Assembled on the frame 1, the movable hammer plate 7 and the fixed hammer plate 5 are both provided with mesh holes 6 arranged in a network structure, and the movable hammer plate 7 and the fixed hammer plate 5 face each other to form a crushing chamber 12.

[0035] One side of the lower end of the weight 4 is pivotally connected to the shear force adjustment rod 8, which can be adjusted on the frame 1 through an arc-shaped guide rail 9, and the shear force adjustment rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com