Blast type combustor

A burner and air blast technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve problems such as secondary air uniformity, high energy, high efficiency, and affecting combustion conditions, and achieve air volume Controllable, full combustion and uniform air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

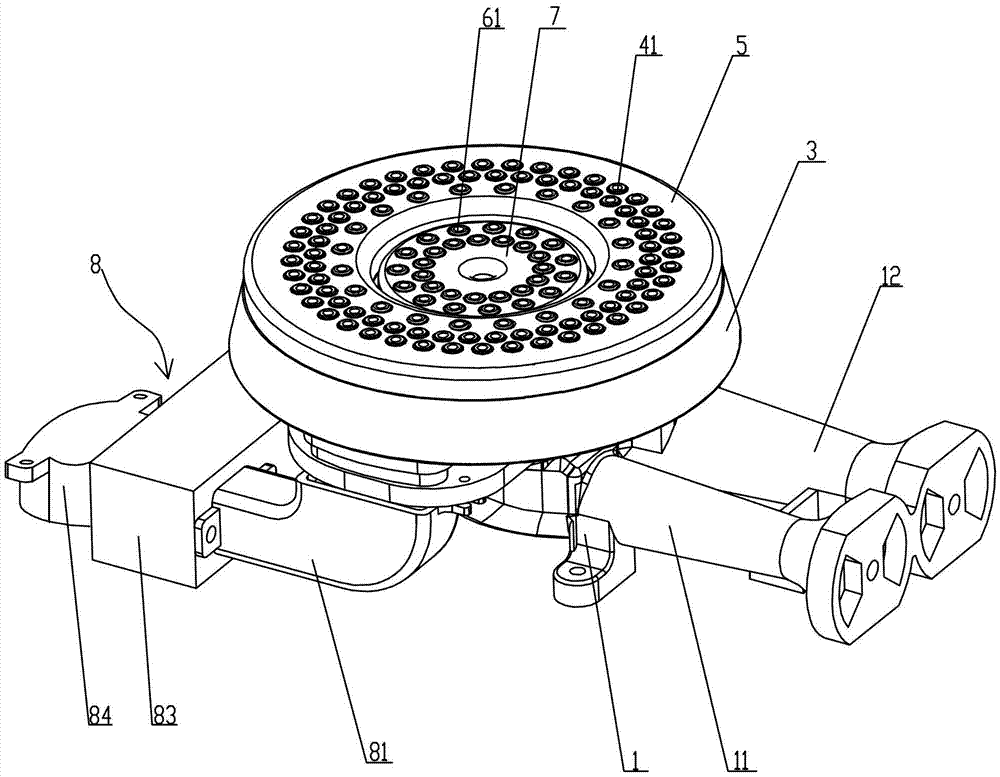

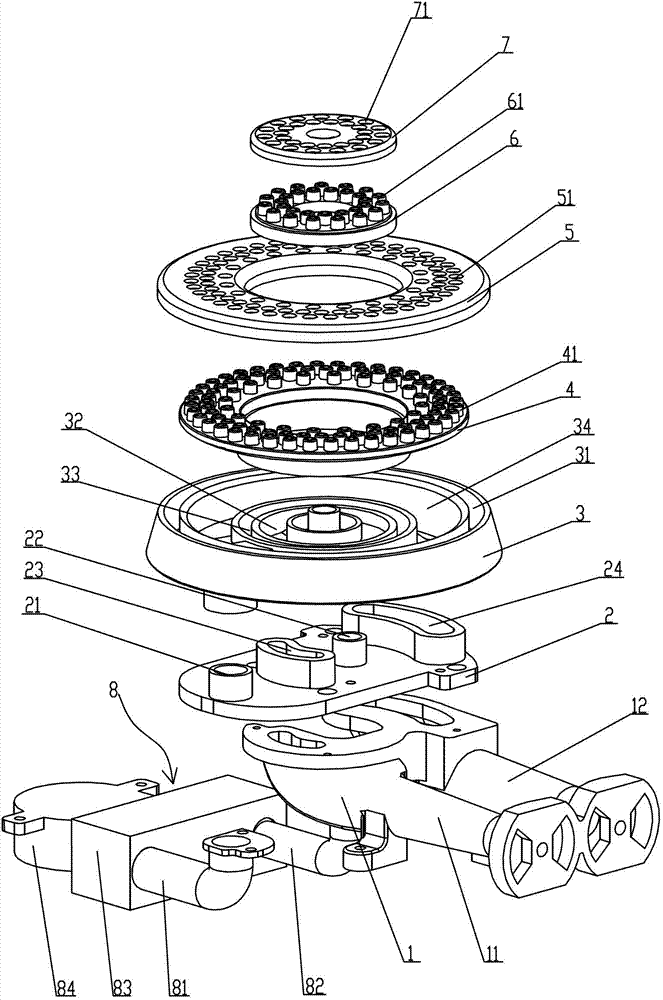

[0020] Example 1, such as Figure 1 to Figure 4 As shown, a blast burner, a blast burner, includes a burner 1, the burner 1 is provided with an inner injection tube 11 and an outer injection tube 12, the primary air is from the burner 1 The shrinking tube of the gas is mixed with the gas and then enters the inner ring injection tube 11 and the outer ring injection tube 12 . The burner head 1 is provided with a burner base 2, and the burner base 2 is provided with a first outer ring air channel 21, a first inner ring air channel 22, and a first inner ring gas channel 23 communicating with the inner injection pipe 11 And the first outer ring gas passage 24 communicating with the outer injection pipe 12; the burner base 2 is equipped with a blast device 8, and the blast device 8 is provided with an outer ring air pipe 81 communicating with the first outer ring air passage 21 With the inner ring air pipe 82 communicating with the first inner ring air channel 22 , the blower devic...

Embodiment 2

[0021] Example 2, such as Figures 5 to 7 As shown, the difference from Embodiment 1 is that the second outer ring gas channel 34 is located outside the second outer ring air channel 31, the outer fire cover 4 covers the second outer ring air channel 31, and the outer ring cover 5 covers the second outer ring air channel 31. The second outer ring gas channel 34 cover, the second outer ring air channel 31, the outer ring fire hole 41, the outer ring cover hole 51 and the second outer ring gas channel 34 are connected in sequence, and the secondary air flows out from the outer ring fire hole 41 , and the gas flows out through the outer ring cover hole 51 and converges at the fire outlet, so that the middle of the fire outlet is secondary air, and the gas is supplemented around it. Each fire outlet has a separate hole to supplement air, so that each fire outlet can be separated. Add secondary air. The second inner ring air channel 32 is located at the outside of the second inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com