Multi-cylinder rotary type compressor

A rotary compressor and multi-cylinder technology, which is applied to rotary piston/swing piston pump components, elastic fluid rotary piston/swing piston pump combinations, mechanical equipment, etc., can solve the lack of shaft rigidity , the reduction of piston efficiency, the increase of the compression load of the compression chamber, etc., to achieve the effect of improving wear failure and compression efficiency reduction, improving rigidity and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

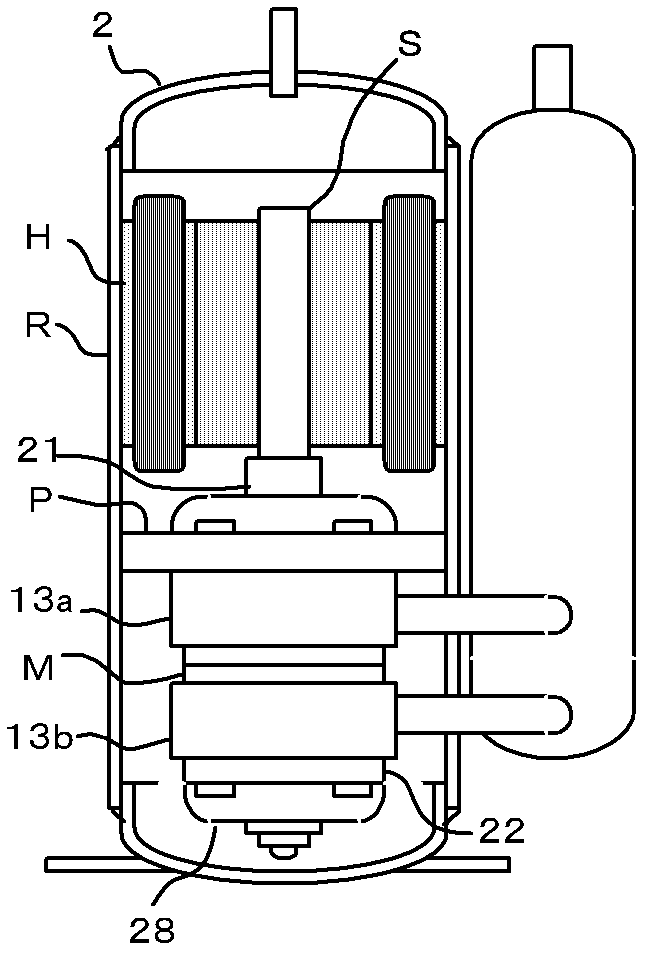

[0039] see figure 1 , is the internal structure of the rotary compressor R. The rotary compressor R is equipped with a compression mechanism P and a motor H in a sealed casing, which are fixed at the inner wall of the casing. The first cylinder 13a and the second cylinder 13b of the compression mechanism P are partitioned by a partition M.

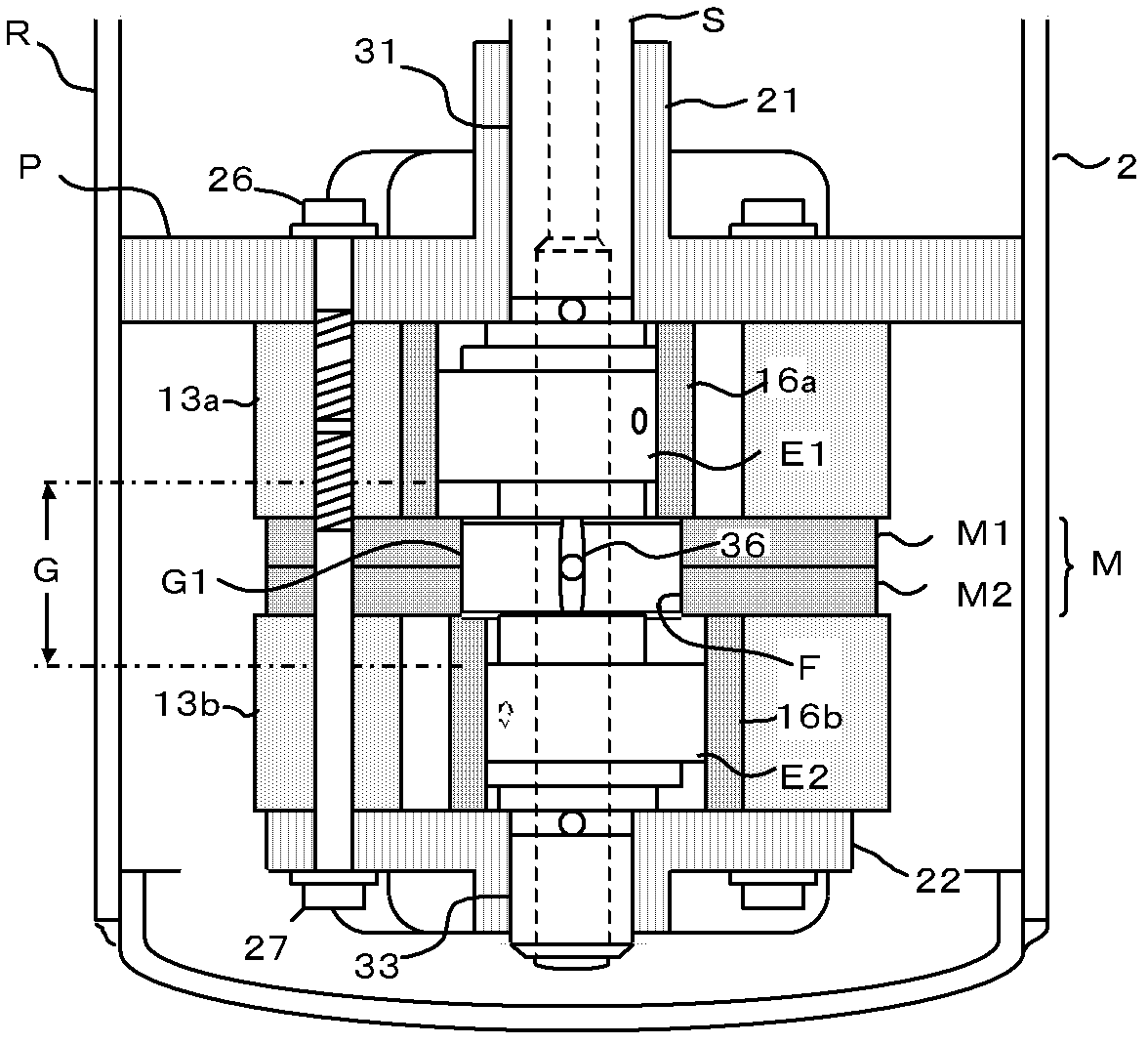

[0040] see figure 2 , is a detailed view of the compression mechanism P. In the first cylinder 13a and the second cylinder 13b constituting the compression mechanism P, a first piston 16a and a second piston 16b are arranged, and slide plates (not shown) that reciprocate in synchronization with them are arranged. A central partition M consisting of a first plate M1 and a second plate M2 divides the two cylinders between these cylinders.

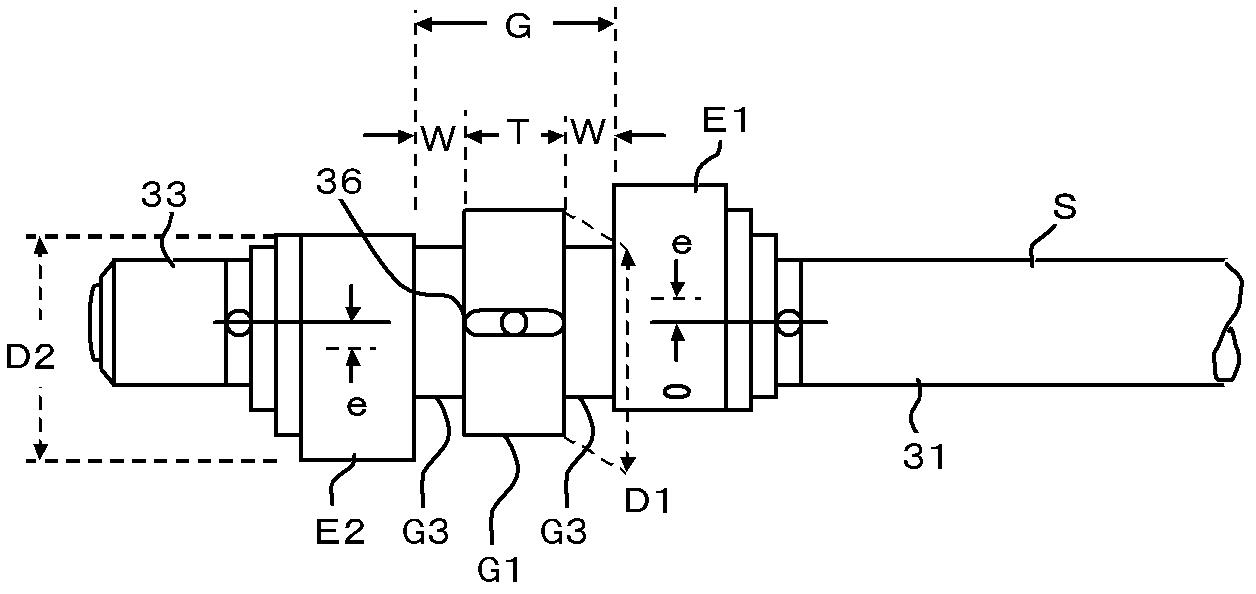

[0041] The connecting shaft G of the eccentric crankshaft S arranged at the center of the compression mechanism P is a shaft connecting the first eccentric shaft E1 and the second eccentric shaft E2,...

Embodiment 2

[0053] see Figure 9-Figure 10 , in this embodiment 2, a central groove 45 with an inner diameter of d2 is disposed in the center of the second plate M2, and a central hole 44 with an inner diameter of d1 is opened on the outer plane of the central groove 45 .

[0054] In Embodiment 2, the inner diameter d3 of the central groove 45 is the inner diameter of the intermediate bearing F, so d2=d3. d2=d1+2e, a thin-walled thrust portion 46 is formed at the bottom of the central groove 45, see Figure 10 . As in Embodiment 1, d2=d3=D1+c. Also, d1=D2+c.

[0055] see Figure 11 , represents the process of inserting the second plate M2 into the eccentric crankshaft S and assembling the middle partition M. Same as Embodiment 1, when the second flat plate M2 moves upward through the outer periphery of the second eccentric shaft E2, as Figure 11 . Moreover, in order to ensure that the center of the center hole 44 coincides with the center of the main shaft 31, it needs to be moved...

Embodiment 3

[0061] see Figure 13 , the present embodiment 3 is that one flat plate constitutes the intermediate partition M, so compared with the embodiment 1 or embodiment 2 in which the intermediate partition M is formed by two flat plates, the processing and assembly of the intermediate partition M are relatively easy. The advantage, the disadvantage is that the width of the intermediate bearing F or the length of the bearing will be halved. However, the condition of increasing the width W of the second intermediate shaft G3 is achievable. Also, in Embodiment 3, the outer diameter D1 of the first intermediate shaft G1 and the outer diameter D2 of the second eccentric shaft cannot be different. That is, D1≈D2.

[0062] See embodiment 1 for all the other undescribed parts, and will not repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com