Circulating water composite corrosion inhibitor

A composite corrosion inhibitor, corrosion inhibitor technology, applied in the direction of descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the adverse effects of metal production, use and secondary processing, corrosion and other problems, to achieve good biodegradability and excellent corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

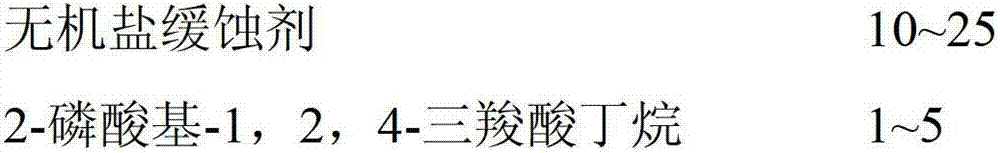

[0020] A circulating water composite corrosion inhibitor consists of the following components in parts by mass:

[0021]

[0022] In this example:

[0023] The inorganic salt corrosion inhibitor is tungstate;

[0024] Described chitosan is that the degree of N-deacetylation is 95%, and the average molecular weight is 1.3×10 6 high degree of deacetylation chitosan.

Embodiment 2

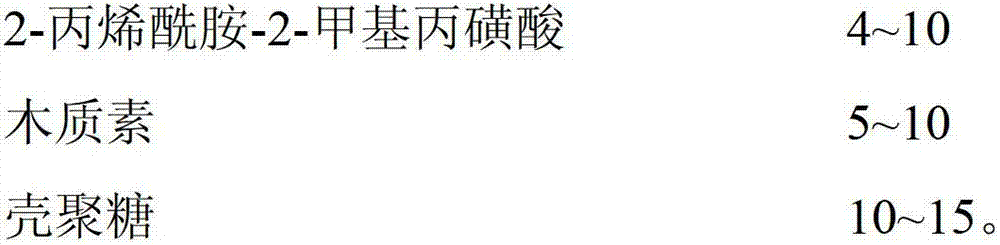

[0026] A circulating water composite corrosion inhibitor consists of the following components in parts by mass:

[0027]

[0028] In this example:

[0029] The inorganic salt corrosion inhibitor is molybdate;

[0030] Described chitosan is that N-deacetylation degree is 90%, average molecular weight is 1.1 * 10 6 high degree of deacetylation chitosan.

Embodiment 3

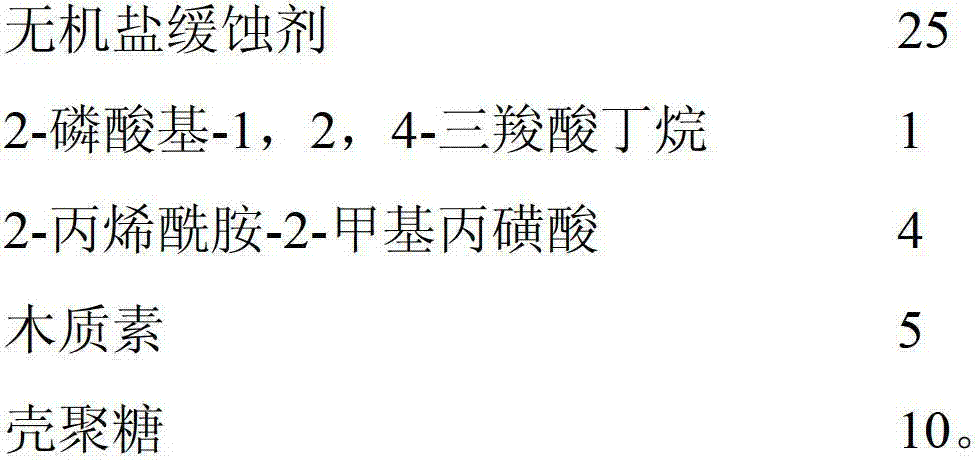

[0032] A circulating water composite corrosion inhibitor consists of the following components in parts by mass:

[0033]

[0034] In this example:

[0035] The inorganic salt corrosion inhibitor is zinc salt;

[0036] Described chitosan is N-deacetylation degree at 75%, average molecular weight is 9.7 * 10 5 Chitosan with a moderate degree of deacetylation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com