Preparation method of rubber-based composite material with super-hydrophobic surface

A technology of super-hydrophobic surface and composite materials, which is applied in the field of preparation of rubber-based composite materials with super-hydrophobic surfaces, can solve problems such as no research reports on super-hydrophobic rubber materials, and achieve large-scale production and application, excellent moisture Effect of wet performance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0023] A method for preparing a rubber-based super-hydrophobic surface, comprising the steps of:

[0024] (1) The aluminum sheet is corroded in a NaOH solution with a mass concentration of 20% for 80 min, then cleaned with deionized water, and dried for subsequent use;

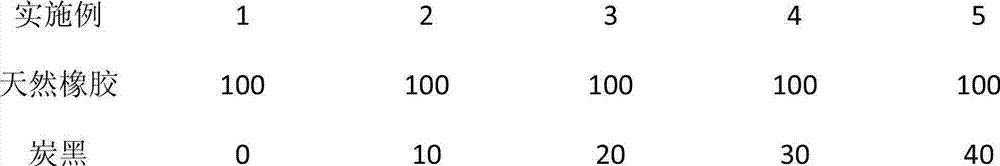

[0025] (2) Put the mixed rubber on the corroded aluminum sheet, vulcanize it on a flat vulcanizer, the vulcanization temperature is 143°C, and the vulcanization time Tc90 is measured by a vulcanization meter. After the sample is cooled, the aluminum sheet and the rubber are peeled off to obtain a rubber-based composite material with a micro-nano rough structure on the surface. In terms of parts by mass, the compounded rubber formula is as shown in Table 1;

[0026] (3) On the rough surface of the peeled rubber-based composite material, brush the ethanol solution of 0.5% hydroxy silicone oil in mass concentration, react in an oven at 80 ° C for 3 hours, take it out and cool it, and obtain a rubber with a super...

Embodiment 1

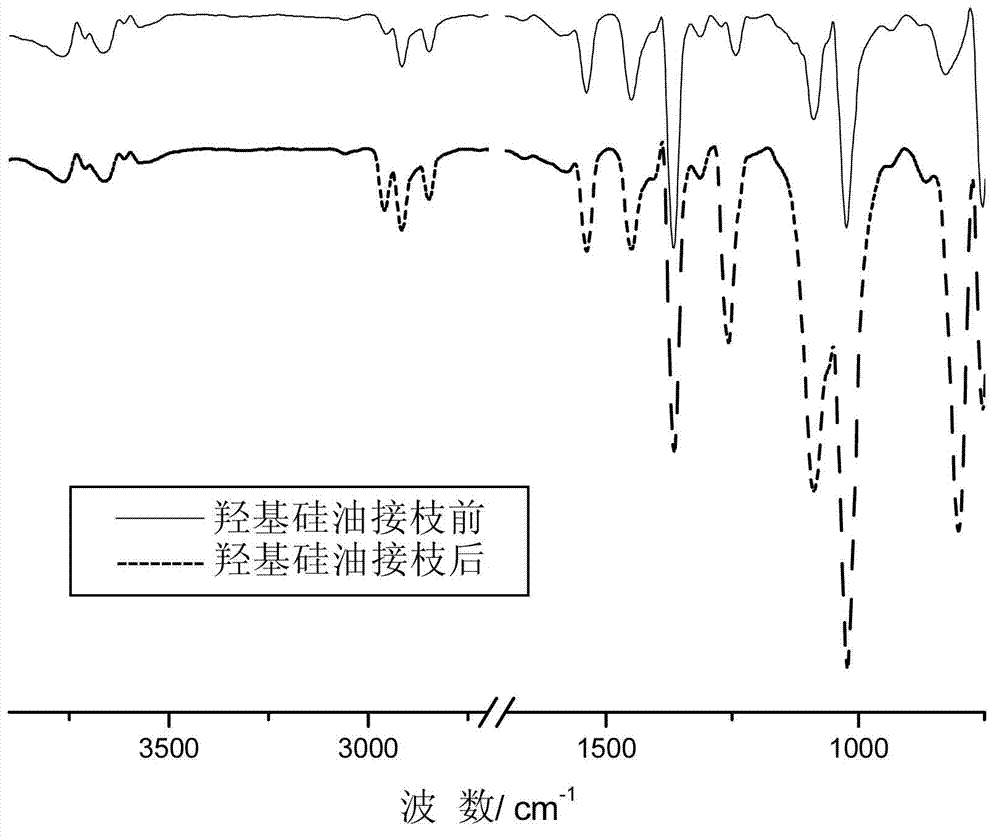

[0034] The infrared spectrograms before and after grafting of materials with hydroxy silicone oil in embodiment 1 can be found in figure 1 , the infrared spectrum of the material surface after grafting is at 1259cm -1 The C-H symmetrical deformation vibration peak on the silicon methyl group appeared, indicating that the surface of the rubber matrix had been grafted with hydroxyl silicone oil.

Embodiment 3

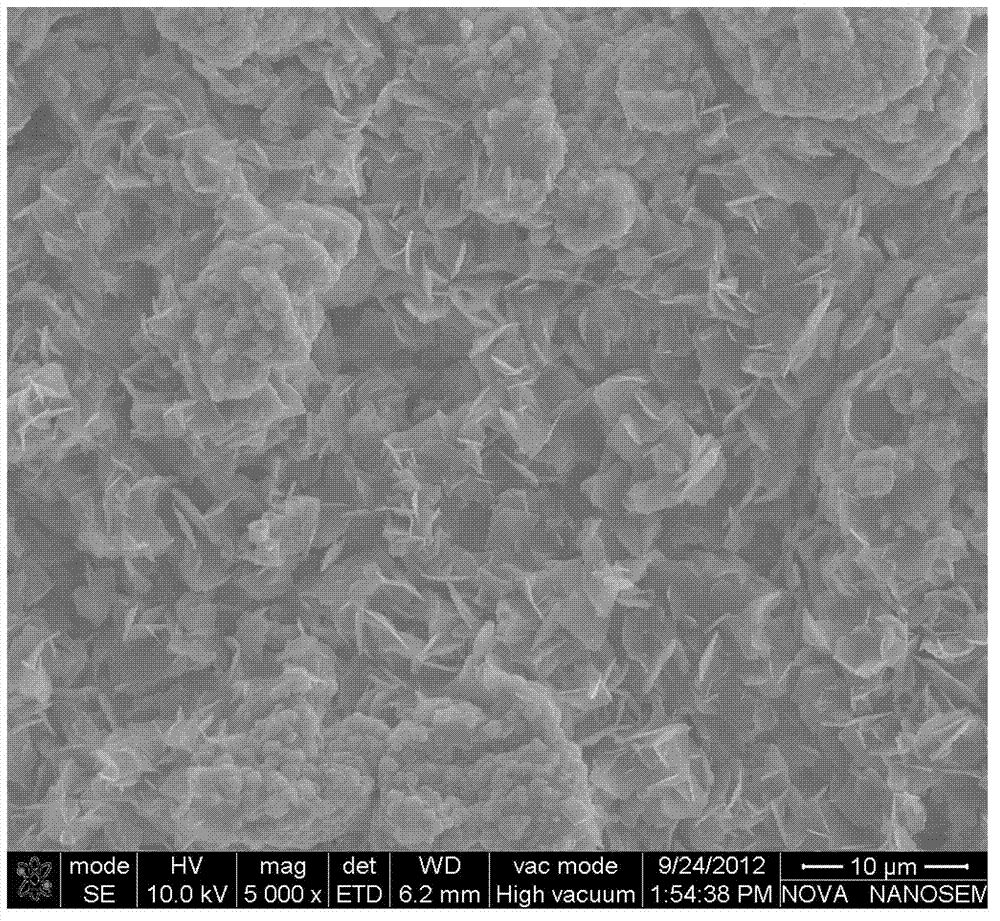

[0035] The surface scanning electron microscope (SEM) figure of the rubber composite material surface with superhydrophobic surface performance in embodiment 3 sees figure 2 . It can be clearly seen that the rubber surface has a fine micro-nano rough structure, which is one of the necessary conditions for a super-hydrophobic surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com