Double-nut tightening device with automatic counting function

An automatic counting and double nut technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome bolts and nuts, difficulty in achieving high unification and standardization of manual tightening nuts, and achieve the goal of improving automation production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

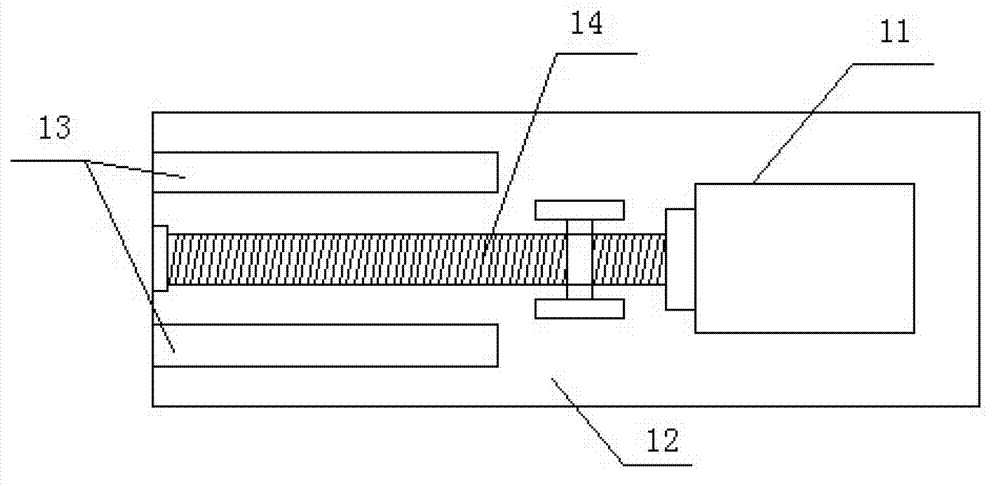

[0009] like figure 1 , figure 2 As shown, a double nut tightening device with automatic counting function includes a connecting shaft support frame 1, a double tightening head 2, a torque sensor 3, a first servo motor 4, a double tightening head spacing adjustment device 5, a connecting shaft 6, The second servo motor 7, the counting display screen 8, the second servo motor support frame 9, the guide rail moving table 10, the third servo motor 11, the base 12, the linear guide 13, the ball screw 14, and the third servo motor 11 are installed on the base 12, the ball screw 14 is connected with the third servo motor 11, the guide rail moving table 10 is connected with the lead screw 14 and installed on the horizontal guide rail 13, the guide rail moving table 10 is installed through the support frame 1 and the support frame 9. The second servo motor 8, the other end of the connecting shaft 6 is connected to the double tightening head spacing adjustment device 5, one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com